3 ROOFING UNDERLAYMENT

3.1 Purpose

Roof coverings such as clay or concrete roof tiles, slate, or roof shingles (discontinuous roofing) allow water to penetrate the roof covering to varying degrees. These types of roof covering will typically be installed with an underlayment to avoid precipitation (snow and rain) from penetrating the primary roof covering.

Traditionally, many discontinuous roof coverings were built using mortar bedding or some other form of sealant (such as roof putty or mortar) to weatherproof the roof. This is still a workable solution if the underside of the roof covering is freely accessible for maintenance, although it is not especially practical.

If the loft space is utilised or the house is constructed with a habitable loft space or couple roof, the use of roofing underlayment is often the only solution, because it is impossible to maintain such mortar bedding or weatherproofing of the roof covering in the traditional fashion.

Water penetration is not usually a problem when using certain roof coverings such as metal sheets. However, condensate may appear on the underside due to night time cooling as the roof radiates to the atmosphere. Condensate may drip on to the thermal insulation and, in severe cases, moisture may accumulate during winter and penetrate the assembly. It will then be possible to drain off the condensate via roofing underlayment to avoid problems of moisture absorption.

To avoid moisture problems in the roof assembly, the underlayment must do the following:

- It must collect and drain off the small amounts of moisture (or condensate) that might penetrate the roof covering.

- It must allow moisture from the inside to diffuse, mitigating the risk of harmful moisture absorption, which may result in black mould, decay, and dry rot in the roof structure. Moisture from the inside is removed by ventilation below the roofing underlayment and/or by diffusion through the underlayment material.

Water from the roofing underlayment must, as a rule, be discharged into the gutter. For single-family dwellings with a relatively tight roof covering, water from the underlayment can be drained off behind the gutter.

Roofing underlayment is available in various materials and qualities, in rolls, as sheeting, or combinations of these. A distinction is made between freely suspended membranes or flexible sheets and firm underlayment (i.e., a membrane on board or plywood decking). In terms of moisture, roofing underlayment is divided into two main types:

- Vapour-impermeable underlayment where moisture from the inside is removed by ventilation on the underside of the underlayment.

- Vapour-permeable underlayment where moisture from the inside is removed by diffusion as water vapour through the underlayment material.

Vapour-impermeable underlayment can be used in vented roof assemblies. Vapour-permeable underlayment can be used in both unvented and vented roof assemblies (see Section 2.3, Roof Ventilation, and Section 3.2, Vapour-Control Function).

Requirements regulate underlayment performance in terms of airtightness, tent effect, strength, durability, and fire reaction are relative to the building type and storey height, roof covering, roof pitch, the overall roof complexity, the possibility of maintenance, and impact from the outdoor climate (terrain category) for example. For assistance in the choice of underlayment, please consult DUKO's website (www.duko.dk) (Dampspærre- og Undertagsklassifikationsordning) (Vapour Barrier and Roofing Underlayment Classification Scheme).

Information on underlayment is also available from TRÆ 67, Undertage (Roof Underlayment) (Træinformation, 2013), Undertage – opbygning, materialer og projektering (Underlayment – Assembly, Materials, and Design) (Byg-Erfa, 1997), Frithængende undertage af banevarer – monteringsdetaljer (Freely Suspended Roll-Material Underlayment – Installation Details) (Byg-Erfa, 2015c), and Undertage – diffusionstætte og diffusionsåbne (Roofing Underlayment – Vapour-Impermeable and Vapour-Permeable) (Byg-Erfa, 2007).

3.1.1 Applicable Standards for Roofing Underlayment

Membrane underlayment is subject to the standard DS/EN 13859-1, Flexible sheets for waterproofing – Definitions and characteristics of underlays – Part 1: Underlays for discontinuous roofing (Danish Standards. 2014a).

3.1.2 Spacer Bars

Spacer bars are used in roofs with underlayment to:

- Raise the battens to enable water and dirt to pass underneath

- Ensure effective fixing of the underlayment

- Ensure adequate ventilation on the underside of the roof covering in conjunction with air-intake at the eaves and exhaust at the ridge

The thickness of the spacer bars should be at least 25 mm and they should be made of pressure-treated timber or similar material. The treatment must not be harmful to the underlayment and the bars must be resistant to moisture impact exposure.

Spacer bars must be made of sharp-edged, pressure-treated timber according to DS/EN 351-1:2007 (Danish Standards, 2007b) or according to the guidelines issued by Nordisk Træbeskyttelsesråds (The Scandinavian Wood Preservation Council) (NTR AB, NTR Gran/Spruce) (Nordisk Træbeskyttelsesråd, 1998). The spacer bars also ensure continuity between the vent openings (e.g., at the eaves and ridge as well as effectively fixing the underlayment).

Battens are usually fixed to the rafters through the spacer bars. However, battens may also be fixed indirectly. In this case, the thickness of the spacer bars should be at least 32 mm and they should be nailed to the rafters close to the battens. The battens are then fixed to the spacer bars (cf. TRÆ 65, Taglægter (Roof Battens) (Træinformation, 2011b)).

Issues concerning roof battens are outlined in Section 2.6.1, Roof Battens.

3.2 Vapour-Control Function

The function of the underlayment should be viewed in conjunction with the function and effectiveness of the vapour barrier. Regardless of the type of roof assembly, small amounts of moisture will be able to penetrate the assembly from the inside. To avoid moisture accumulation, moisture rising from the inside must be removed in tandem with its formation.

A distinction is made between two types of underlayment assemblies, namely vented and unvented assemblies.

- In a vented assembly, moisture is removed via ventilation below the underlayment.

- In an unvented assembly, vapour-permeable underlayment is uses (i.e., products that are sufficiently vapour-permeable/porous to water vapour to allow moisture to diffuse through the material). Normally, underlayment with a Z-value of less than 3 GPa s m2/kg is regarded as vapour-permeable.

Vented and unvented underlayment assemblies will only function correctly if moist air is effectively prevented from migrating into the roof assembly. If excessive moisture is allowed to migrate into the roof assembly, neither ventilation nor diffusion will be able to remove it.

Effective prevention of moisture ingress is usually implemented by:

- Using vapour-impermeable materials (i.e., materials with a high Z-value on the warm side of the insulation, e.g. a vapour barrier (possibly in the form of sheeting). The materials will reduce or prevent diffusion.

- Constructing airtight assemblies, for example using a vapour barrier or sheeting installed with airtight joints, intersections, and penetrations achieved using vapour-barrier tape or foil adhesive. The airtight installation will prevent moisture ingress caused by convection (airflow).

Old roof assemblies must also be airtight. For example, plaster coats must be intact and without cracks and existing vapour barriers must be executed with airtight joints and penetrations, trapdoors must be tight and there must be no openings in joints between walls and ceilings.

If a vapour barrier is already in place, its tightness must be checked. Special attention must be paid to joints, intersections, and penetrations. To be on the safe side, the tightness of an existing assembly can be checked by conducting an airtightness check (see Section 2.4.3, Airtightness).

Vapour barriers must be made of durable and vapour-impermeable material with a min. Z-value of 50 GPa s m2/kg, unless documentation specifies that a lower Z-value is adequate in a systems solution (e.g., by calculation) (see Section 2.1.2, Vapour Barriers in Roofs).

If there is any uncertainty about the tightness of an existing vapour barrier or doubt as to the possibility of constructing a tight vapour barrier, we recommend installing a vented underlayment assembly. Alternatively, a new vapour barrier must be fitted.

Regardless of the underlayment type, venting must be established on the underside of the roof covering to avoid condensate and frost damage to the roof covering. To ensure unobstructed ventilation and discharge of precipitation between battens and underlayment, spacer bars must be fitted on top of the rafters and underlayment (see Section 3.1.2, Spacer Bars).

Gangways, made of tight material in loft spaces such as plywood sheets or abutting wood boards must be raised 20–30 mm above the thermal insulation to ensure free air circulation underneath them, removing any moisture that could be rising from below. Care should be taken in raising the gangway if it forms part of the general stabilising system of the building.

3.1.2 Vented Roofing Underlayment

Underlayment has traditionally been installed as a vented assembly, meaning that moisture migrating into the assembly from the inside is removed from below the underlayment via outside-air ventilation. Firm underlayment such as roofing membranes on a sheeting or wood board decking and roll-material underlayment is vapour-impermeable and must therefore always be vented on the underside. During renovation, plastered loft spaces can, in some cases, adequately ensure airtightness (cf. Section 8.2.3, Vapour Barriers and Roof Renovation).

Vent openings complying with the general rules for installing ventilation in roof assemblies must be established to vent the underside of the underlayment (see Section 2.3, Roof ventilation). From the vent openings, air flows through the loft space or through a vent space between the thermal insulation and the underlayment.

In couple roofs, the vent space must have a median height of at least 45 mm.

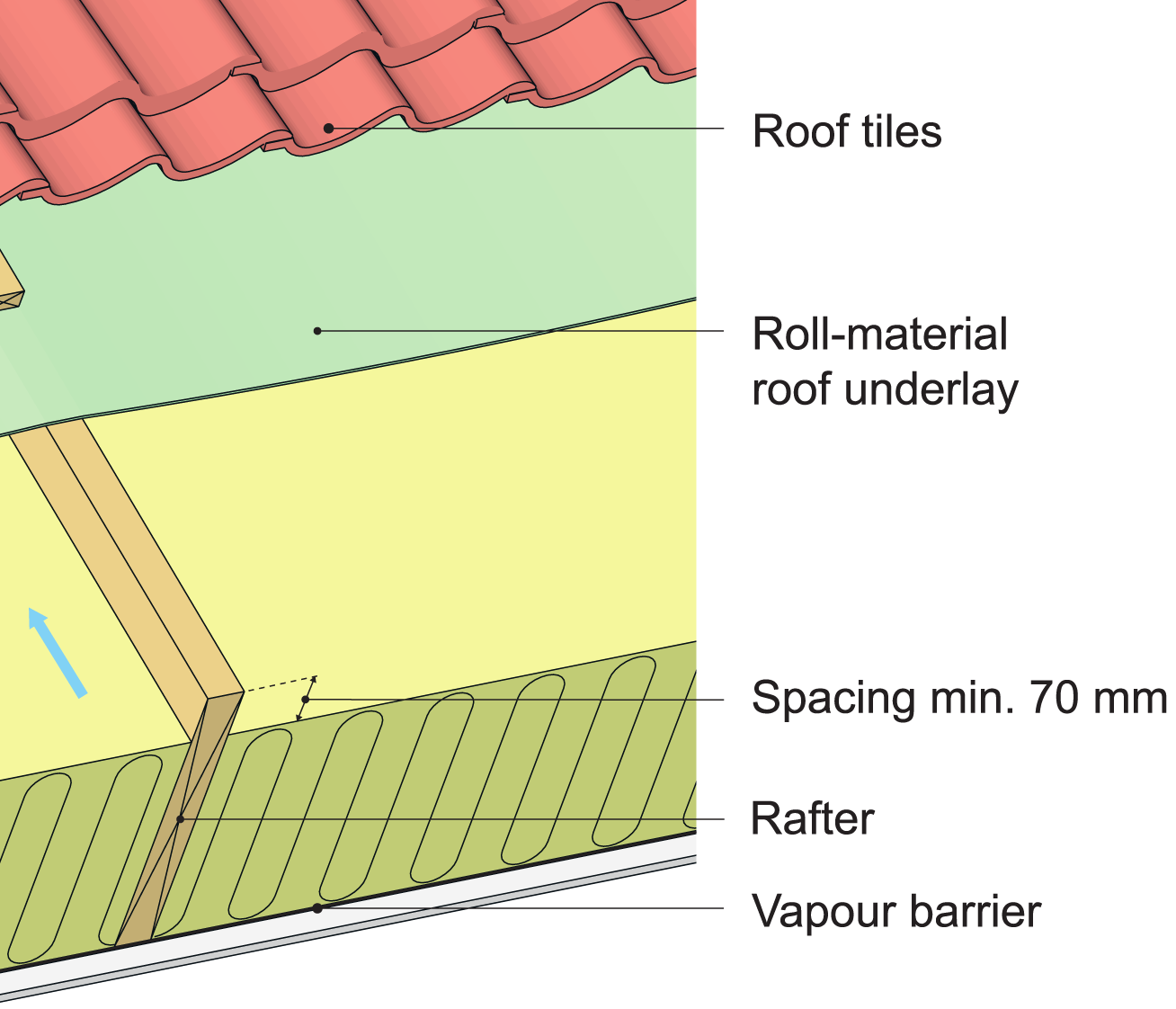

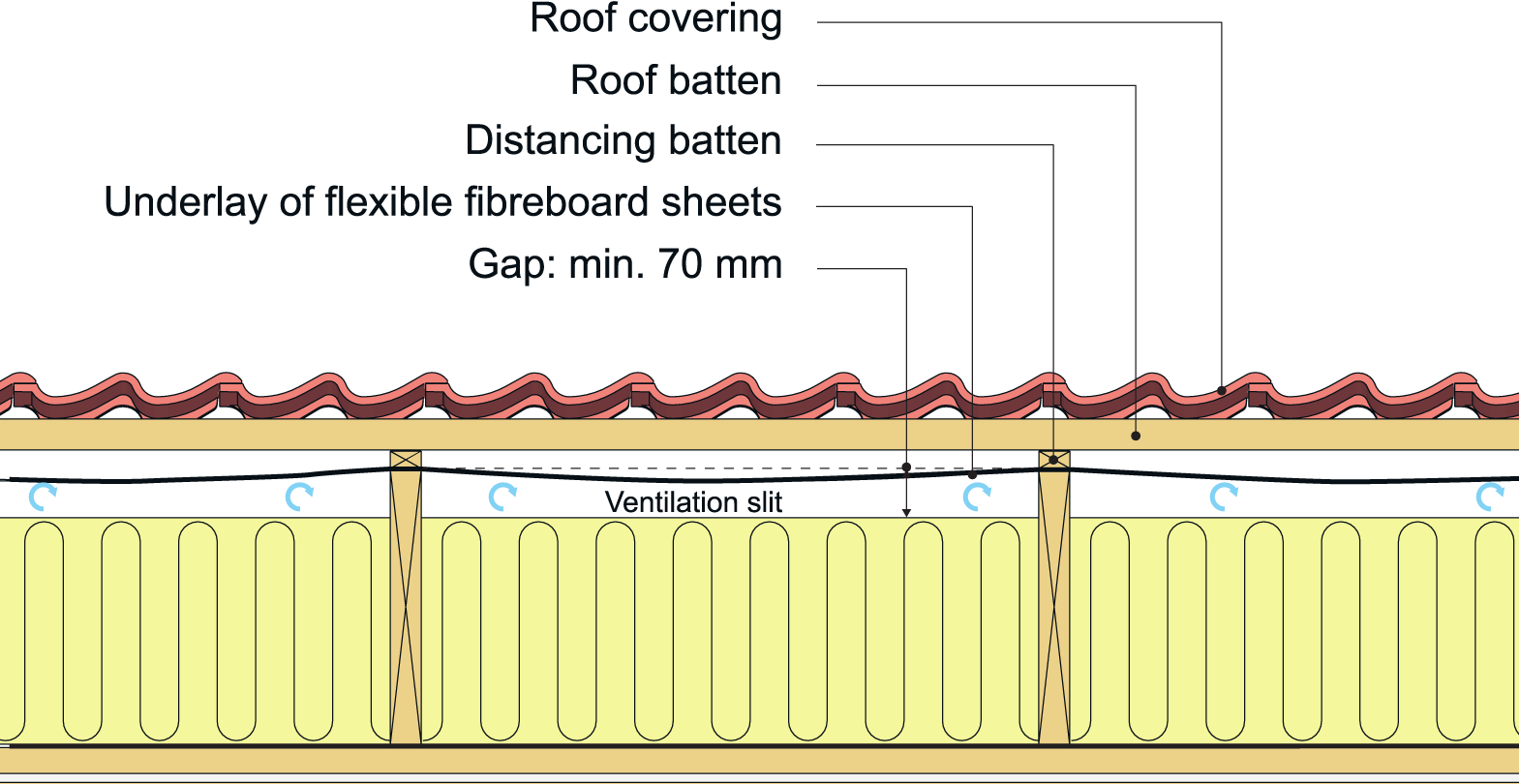

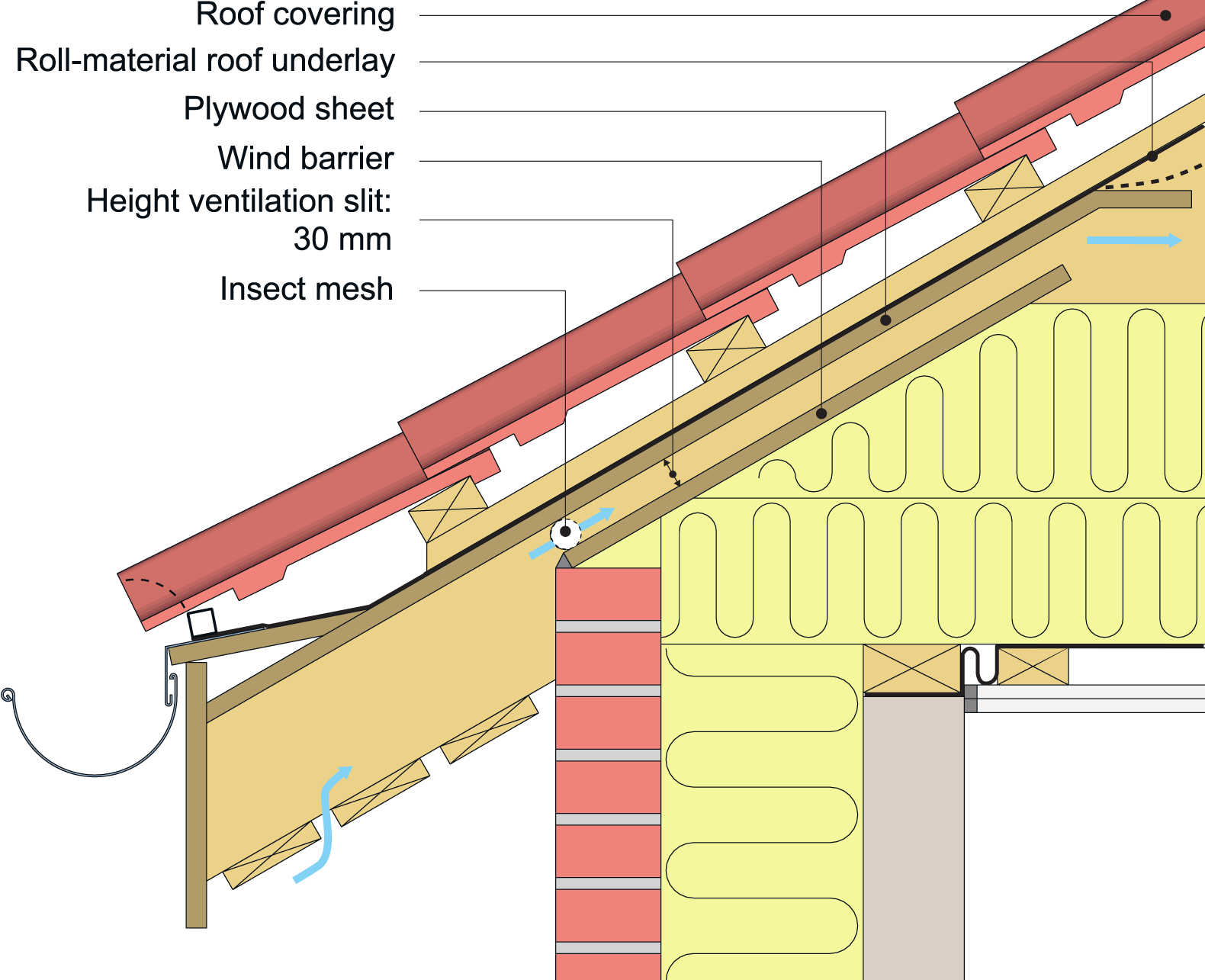

For a firm underlayment, it will be sufficient to specify a vent space height of 45 mm. For roll material and flexible materials (e.g., fibreboard sheets), the specified vent space height must be at least 70 mm, because the underlayment will be fitted between the rafters (see Figure 36).

For roof surfaces on buildings with depths exceeding 16 m, the ventilation conditions should be subject to moisture assessment, factoring in the size of the vent openings as well as the height of the vent space.

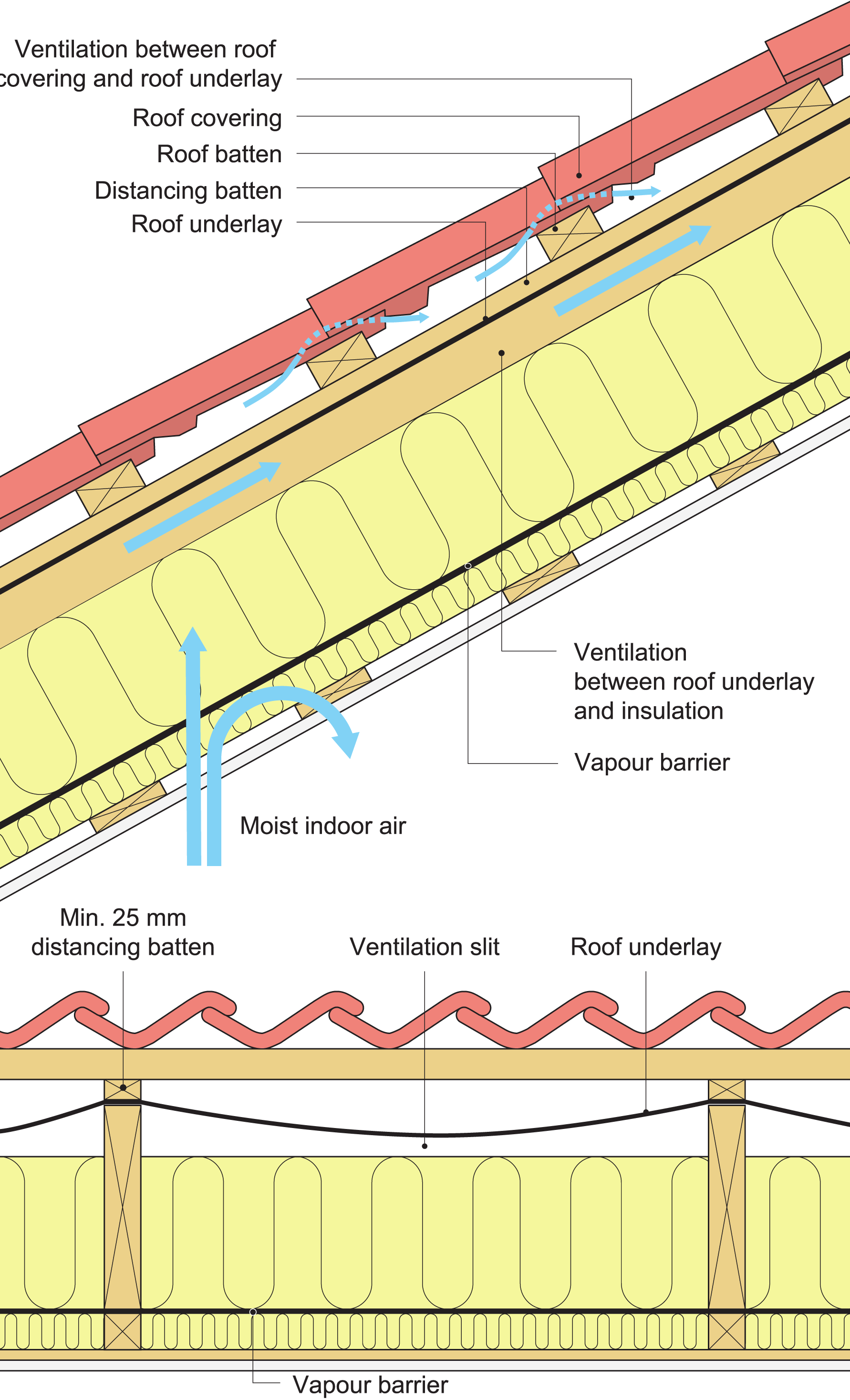

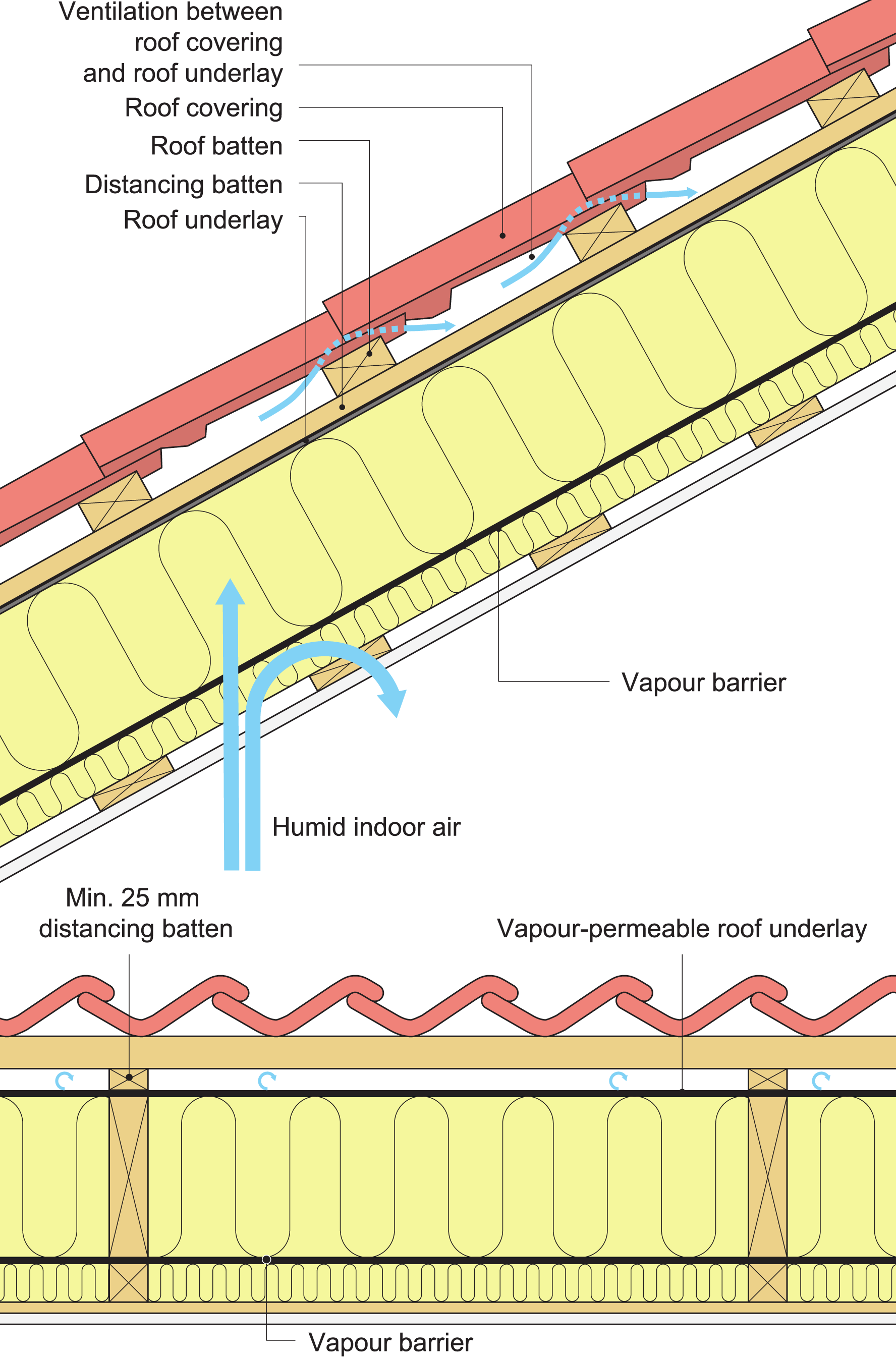

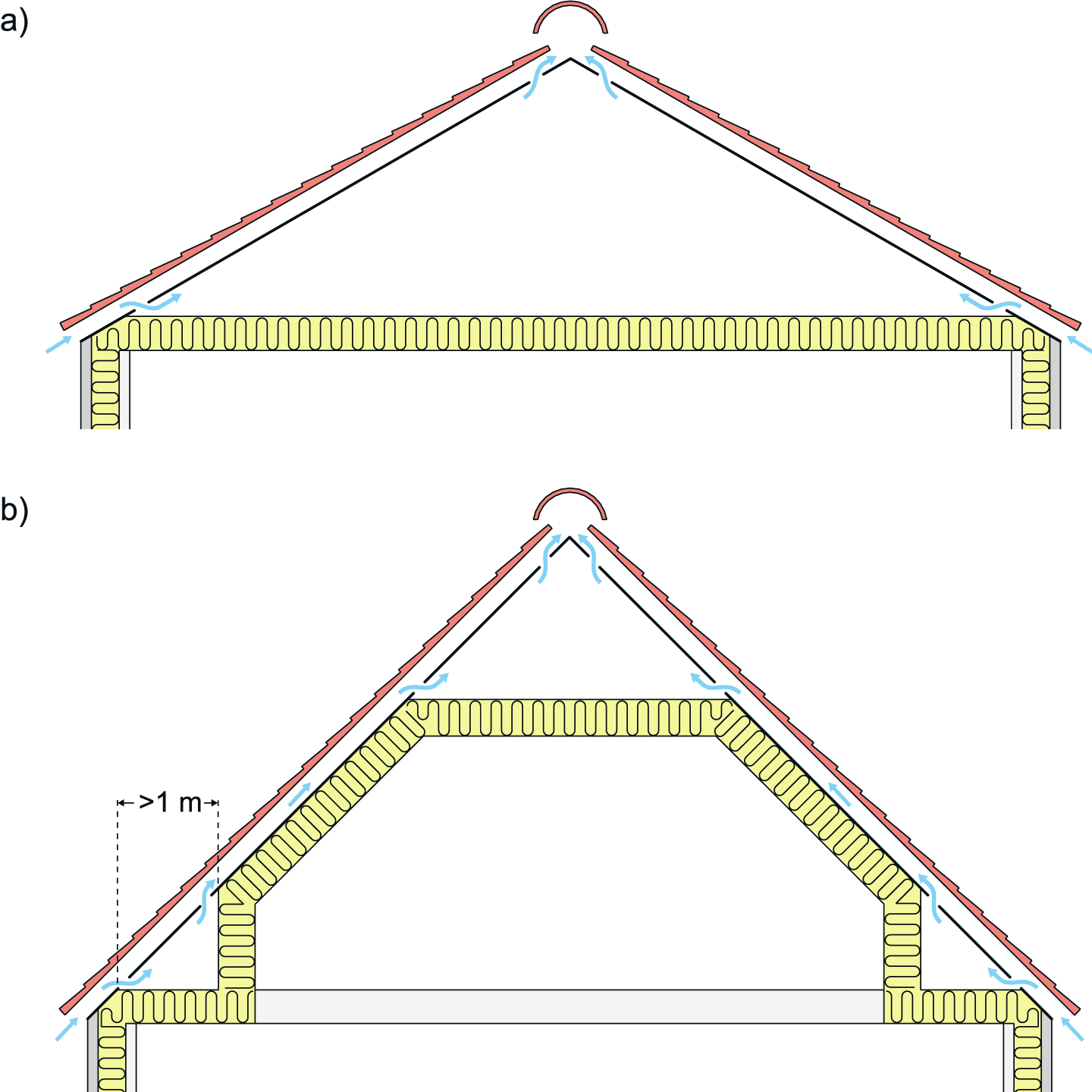

Figure 36. Vented underlayment where the moisture migrating into the roof assembly from the inside is removed by venting the space between the thermal insulation and the underlayment. Installing an airtight vapour barrier will reduce both convection and diffusion of moisture into the roof assembly. The median vent space height must be min. 45 mm, which means that, in the case of roll material and soft-sheet materials, the design vent space height must be 70 mm, because these materials are freely suspended between the rafters as shown in the lower figure. The spacer bar must be pressure-treated (see Section 3.1.2, Spacer Bars).

Figure 37. A vented roof structure with roof tiles and underlayment is a typical example of a cold roof assembly. The supporting structure (the rafters) are, in part, located outside the thermal insulation with direct contact to the outdoor climate. When using roll-material underlayment as shown in the example, always, in a rafter structure, allow a space of min. 70 mm between the thermal insulation and the underlayment to achieve a median vent space gap of 45 mm.

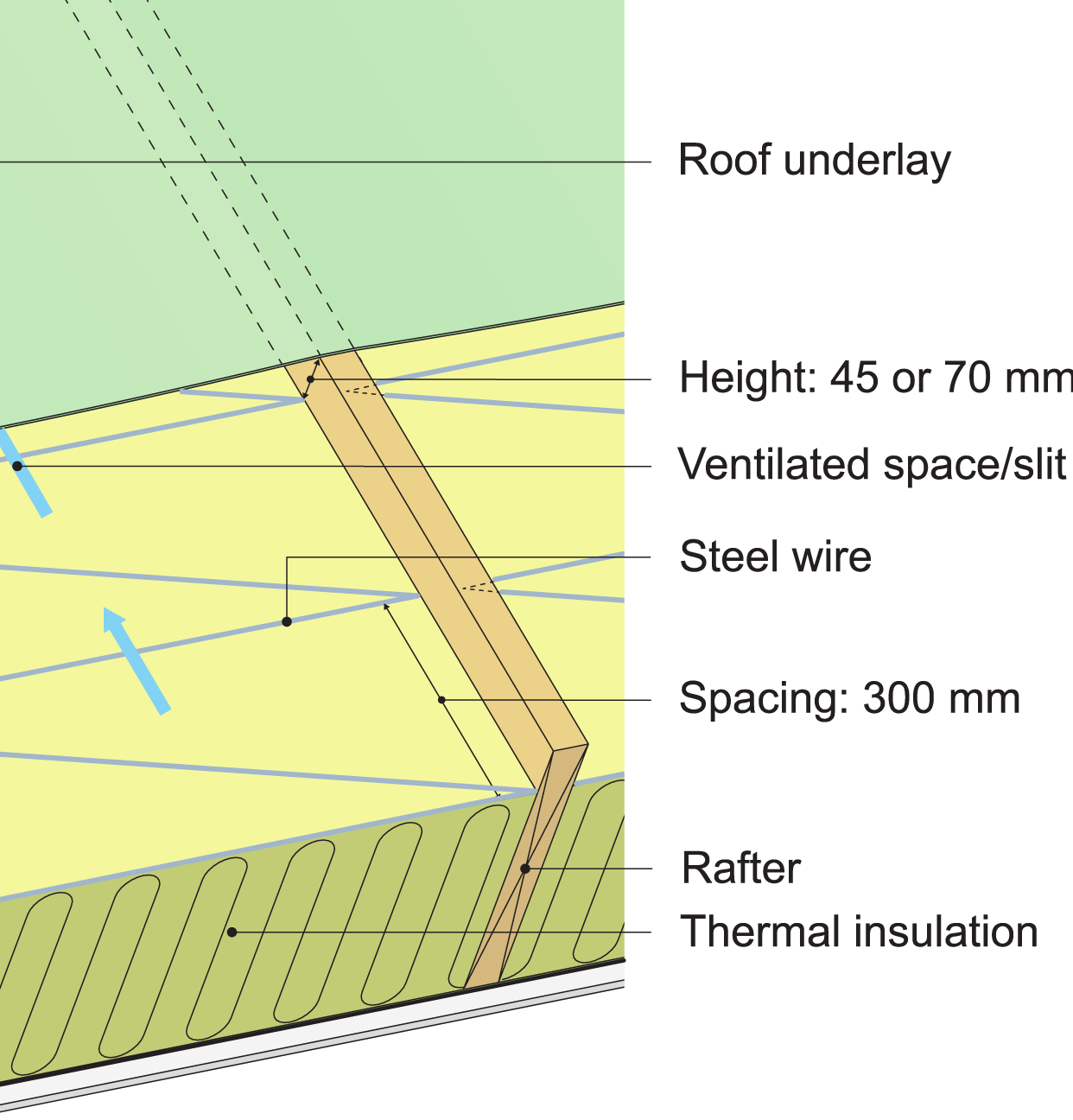

Please note that certain types of thermal insulation are supplied with excess height. There is a risk, therefore, of reducing the effective vent space. When specifying the construction height of vented underlayment, one should remember to allow for the possible excess height of the thermal insulation material. Alternatively, the thermal insulation material must be fixed, for example, with a 2 mm steel wire per 300 mm (see Figure 38).

Figure 38. Certain thermal insulation materials are supplied with excess height. The insulation can be fixed, for example, by 2.0 mm galvanised steel wire per 300 mm on the outer side of the insulation material, to retain vent space height in a vented underlayment assembly, or to prevent buckling of the material in an unvented underlayment assembly. Alternatively, a 20 mm vent space can be specified between the thermal insulation and the underlayment, allowing for the excess height.

3.2.2 Unvented Roofing Underlayment

In unvented underlayment assemblies, there is no vent space between the thermal insulation and the underlayment (see Figure 39). In this case the overall construction height will be reduced by comparison to a vented underlayment assembly with the same thermal insulation thickness.

Figure 39. Unvented underlayment where moisture from the inside is removed by diffusion through the underlayment. A precondition for the unvented underlayment assembly is an airtight vapour barrier which can reduce both the convection and diffusion of moisture migrating into the roof assembly. An unvented underlayment must not be used in conjunction with plastered lofts, because the vapour diffusion resistance of a plastered loft cannot adequately safeguard against diffusion. Furthermore, plastered lofts are prone to damage and so may allow humid indoor air to rise through cracks and holes. The spacer bar must be pressure-treated (see Section 3.1.2, Spacer Bars).

In unvented roof assemblies, captured moisture must be removed by diffusion through the underlayment (i.e., by water vapour penetrating the underlayment). Moisture is then removed from the upper side of the underlayment by venting between the roof covering and the underlayment or via natural leakages in the roof covering, such as the overlap between roof tiles.

Thus, an unvented underlayment must be executed using a material which is both watertight and capable of withstanding precipitation, as well as being open to water vapour diffusion, thereby allowing moisture to escape from the building through the material via diffusion.

To ensure adequate water vapour diffusion, the water vapour resistance factor (the Z-value) of the underlayment material must be less than 3 GPa s m2/kg. Determining the Z-value is done by performing a so-called wet-cup test. The test determines the water vapour permeability by measuring the moisture transmission through the material when it is used to separate two different and relatively humid climates (cf. DS/EN ISO 12572 (Danish Standards, 2016a)).

Although vapour-permeable, the underlayment is only capable of discharging small amounts of moisture. A precondition for the assemblage to function is that an airtight vapour barrier has been established.

Please note that an unvented underlayment must not be used for plastered lofts without vapour barriers as plastered lofts do not provide adequate protection against moisture transmission. This is partly because the Z-value (water vapour resistance factor) for plastered lofts is not comparable to that of the underlayment material, meaning that it is uncertain whether moisture migrating into the assembly from below can be removed fast enough. Furthermore, there will often be cracks in the plaster and a risk of moist indoor air migrating into the roof assembly.

In unutilised loft spaces, collar roof apexes, or in large cold crawl spaces (crawl spaces with a floor width of > 1 m) with an unvented underlayment, thermal uplift may cause an accumulation of moisture. If this is the case, it is particularly important that the vapour barrier is tight, thereby reducing the ingress of additional moisture from below. The installation of at least ’modest ventilation’ would be necessary, such as with 50 cm2 roof vents or vent spaces in every second roof truss in loft spaces, apexes, and crawlspaces (see Figure 40).

Please note that certain types of insulation materials may be supplied with excess height. Thus, there will be a risk that flexible underlayment material is pushed up by the insulation so that the underlayment will buckle and slope towards the rafters. When designing the construction height for unvented underlayment, therefore, remember to allow for the possible excess height of the thermal insulation material, for example, by specifying a space of 20 mm between the thermal insulation and the underlayment. Alternatively, the insulation material should be fixed, for example, using a 2 mm steel wire per 300 mm (see Figure 38).

Figure 40. (a) An unvented underlayment assembly in an open loft space and (b) large crawl spaces (with a floor area width of more than 1 m) and apex. In these a modest form of ventilation (e.g., roof vents placed at the top and bottom of every other roof truss) must be established, because the forward pressure controlling the diffusion is poor in these areas (see Section 2.3, Roof Ventilation)..

3.3 Types of Roofing Underlayment Material

Underlayment can be installed and structured in various ways and can be made of various materials.

A distinction is usually made between the following types or underlayment:

- Firm underlayment

- Roll-material underlayment

- Sheeting.

3.1.1 Firm Underlayment

A firm underlayment is characterised a deck which is strong enough to withstand footfall when installing the underlayment plus its ancillary details. The decking can be made of boards or wood-based sheets such as plywood or OSB sheets. Unsupported joints should be avoided when installing sheet decking (i.e., transverse sheet joints must be supported by battens). Sturdy roll-roofing membranes (such as bituminous felt or roofing foil) are normally used for firm underlayment (cf. Træ 67, Undertage (Underlayment)) (Træinformation, 2013), but lighter roll materials can also be used (cf. www.duko.dk). If the underlayment is to be used for work purposes during the construction period, it must be sufficiently robust to withstand the resultant impacts. Firm underlayment is normally vapour-impermeable and must therefore be vented on the underside.

Apart from functioning as an underlayment, a firm sheeting underlayment will contribute to the absorption of wind as it acts as a shear wall and can serve a bracing function. Boards do not function to the same extent in this way.

For a detailed discussion of the regulations of boards and wood-based sheets used as underlayment for a roofing membrane, see Section 5.7.4, Constructing a Membrane Roof.

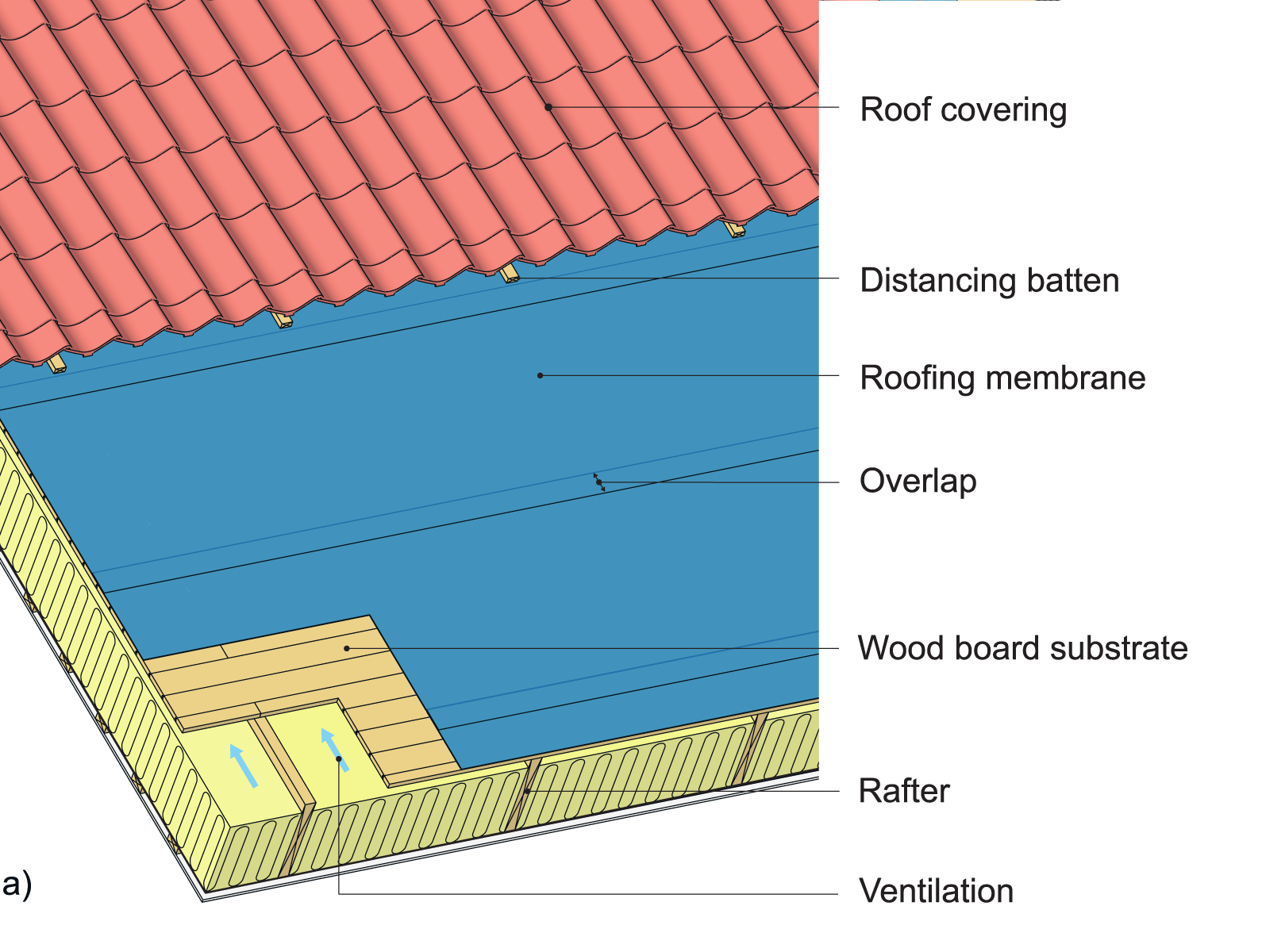

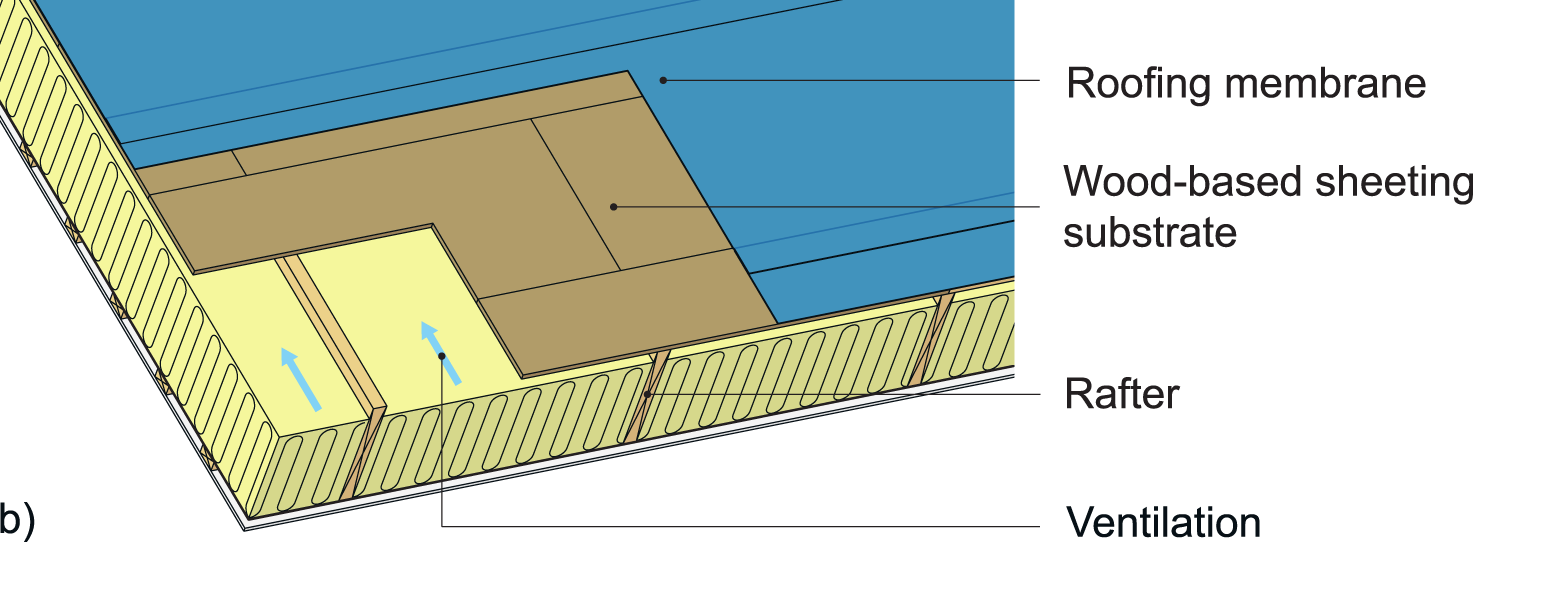

Examples of roof assemblies with firm underlayment are shown in Figures 41 and 42.

Figure 41. Examples of the materials of a roof assembly featuring (a) a vented, firm underlayment of boards and (b) wood-based sheets (also see Figure 42).

Figure 42. Cross section of a roof assembly with vented, firm underlayment. The height of the vent space must be at least 45 mm. Allowances must be made for the excess height of thermal insulation in the design phase (see Figure 38).

3.3.2 Roll-Material Underlayment

Roll-material underlayment is normally comprised of freely suspended membranes installed across rafters (BAR, 2013) and has no bracing function.

Roll-material underlayment is available both in vapour-impermeable membranes, which always require vented assemblies (see Section 3.2.1, Vented Roofing Underlayment), and in vapour-permeable membranes (with a Z-value less than 3 GPa s m2/kg) where moisture from the inside is normally removed by diffusion through the material (see Section 3.2.2, Unvented Roofing Underlayment).

Some roll materials can be installed on a firm decking of wood boards, plywood, or OSB sheets without being classed as roof covering. Such assemblies should be installed with ventilation under the firm decking. Roll materials should only be installed on firm decking when the following conditions are met:

- The wood-based decking should not be exposed to moisture resulting from the tent effect (i.e., decking could absorb moisture if the underlayment material is exposed to water).

- If the underlayment is vapour-permeable, the overall assembly of decking plus underlayment must have a Z-value of less than 3 GPa s m2/kg.

- The installation should be installed as specified by the manufacturer, who must stipulate that installation on firm decking is appropriate.

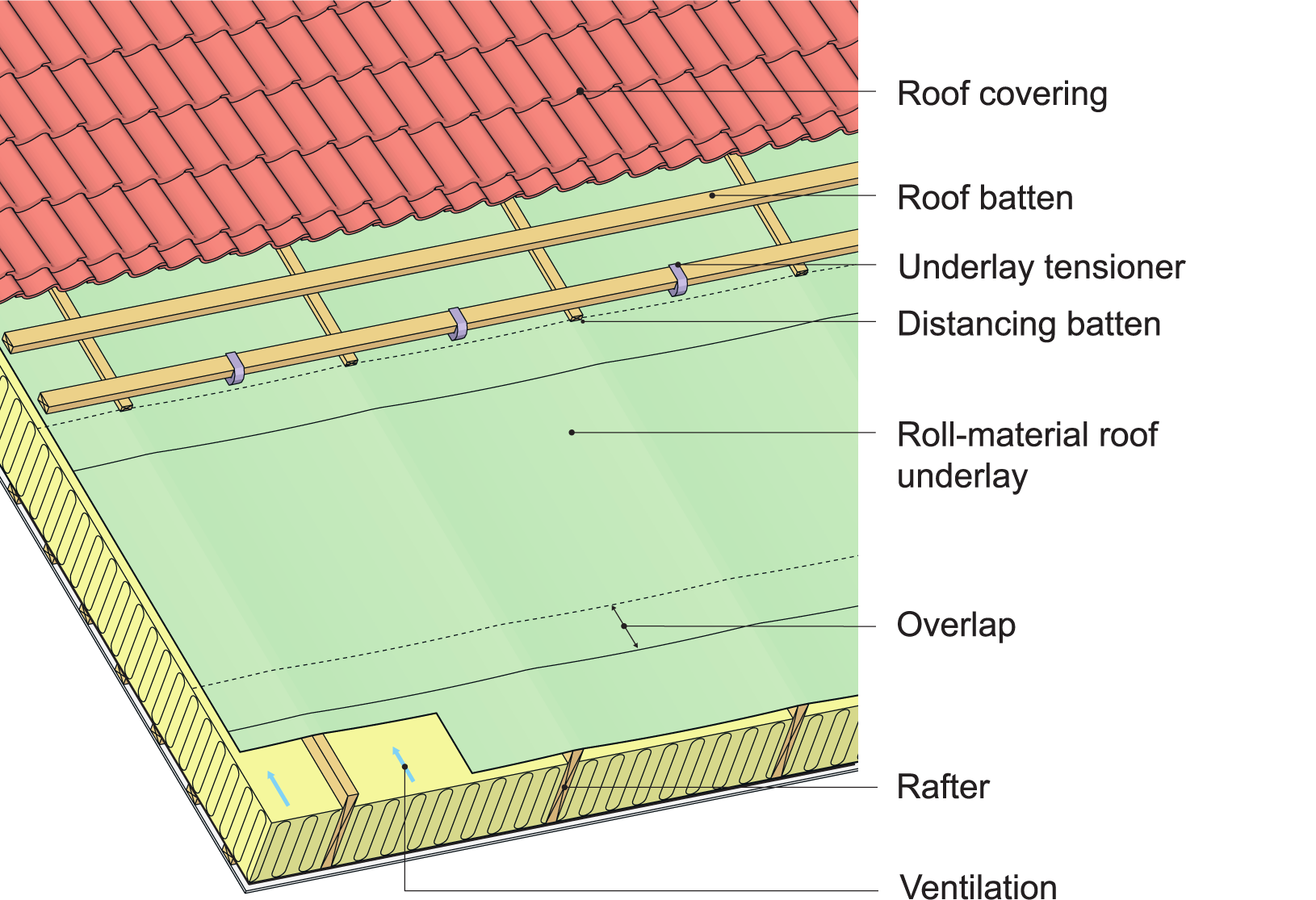

Figures 43 and 44 are examples of roof assemblies with vented underlayment of roll material.

Figure 43. Examples of the roof materials in a roof assembly with a vented roll-material underlayment. An underlayment tensioner is used if needed (i.e., if the underlayment is not sufficiently tight when installed) (see Figure 44).

Figure 44. Cross section of a roof with vented roll-material underlayment. The vent space gap must be min. 70 mm (measured at the rafters). In the design phase, allowances must be made for the possible excess height of the thermal insulation (see Figure 38).

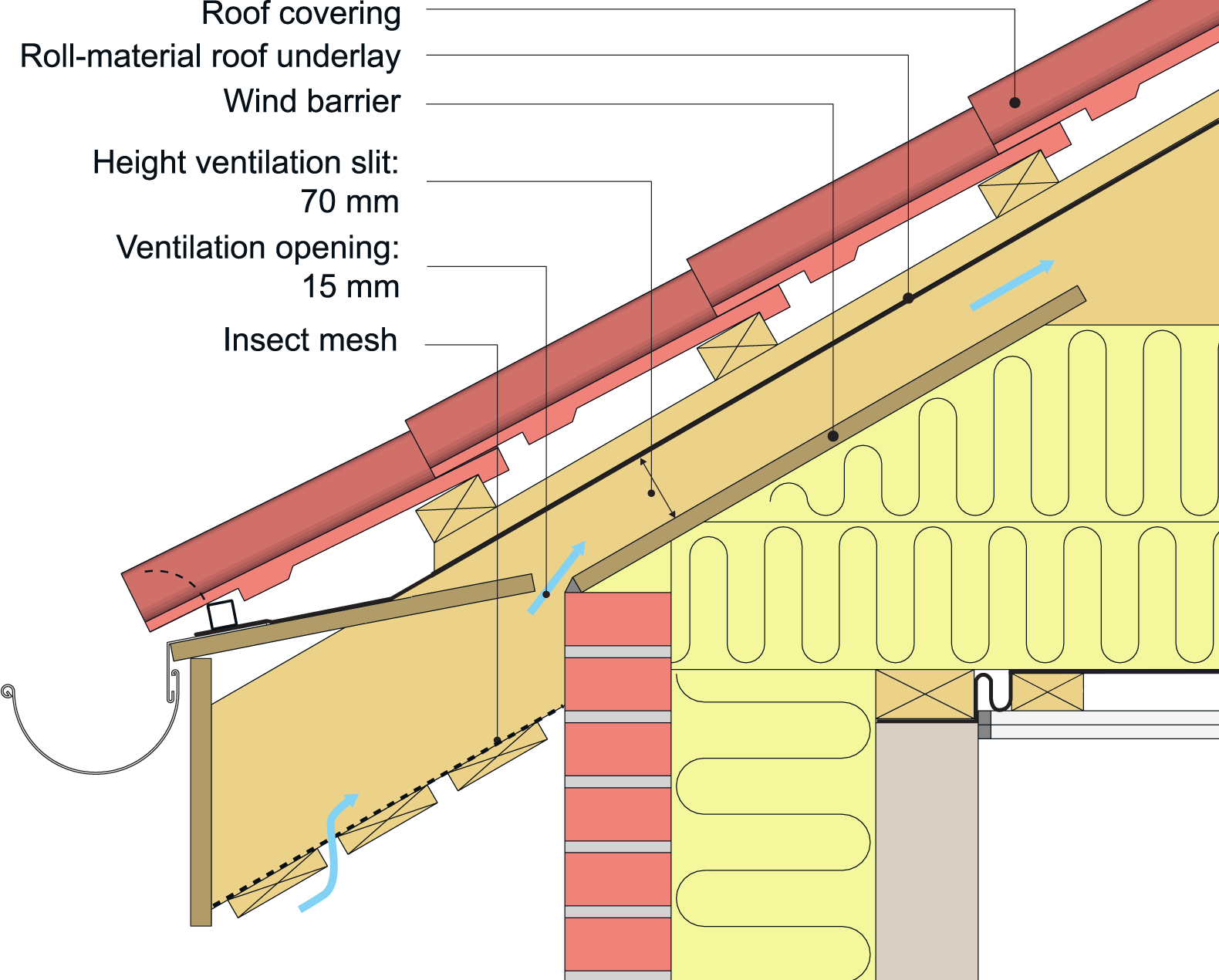

3.3.3 Flexible Sheeting

Flexible sheeting underlayment usually consists of high-density fibreboard sheets. Typically, these are relatively thin vapour-permeable sheets, that have received surface or pressure treatment. The sheets are not walk-proof.

Flexible sheeting underlayment must be waterproof and, when used in unvented underlayment structures, they must be vapour-permeable (with a Z-value of less than 3 GPa s m2/kg) (in keeping with other underlayment products).

Further information about installing flexible sheeting underlayment (fibreboard sheets) is available in TRÆ 67, Undertage (Underlayment) (Træinformation, 2013).

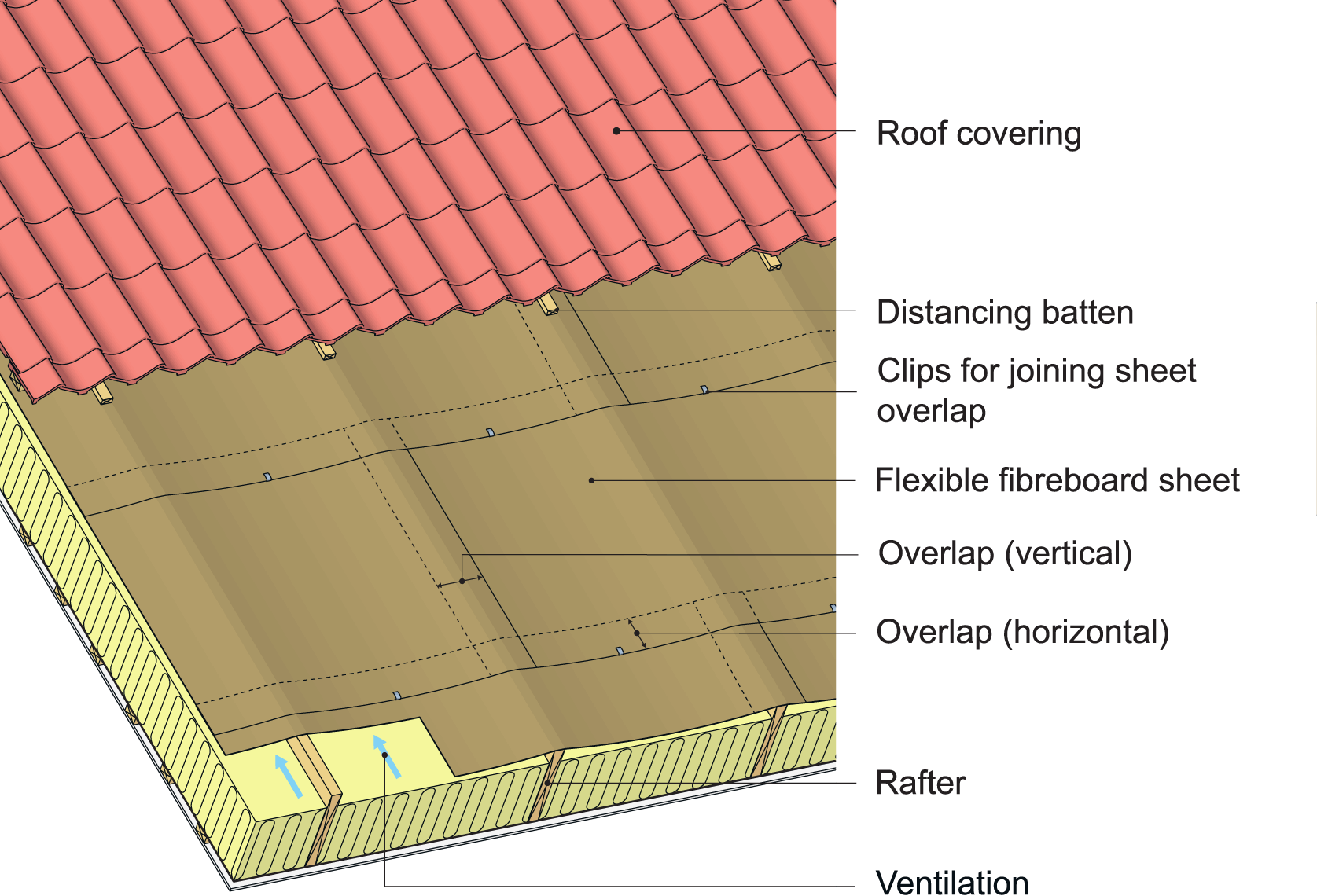

Figures 45 and 46 show examples of roof assemblies with a vented underlayment of flexible fibreboard sheets.

Figure 45. An example showing components of a roof assembly with a vented underlayment of fibreboard sheets. The vent space gap must be at least 70 mm deep (measured at the rafters) (see also Figure 46).

Figure 46. Cross section of roof with a vented underlayment of flexible fibreboard sheets. The vented space height must be 70 mm (measured at rafters). In the design phase, allowances must be made for possible excess height of thermal insulation (see Figure 38.

3.4 Details – Roofing Underlayment

This section features underlayment design with selected details. When specifying the details of an underlayment, each specific case should be considered relative to ventilation guidelines as well as provisions of the Building Regulations concerning fire safety and thermal insulation, for example. General concerns relating to roof choice are treated in Section 1.1, Roof Design.

For examples of detail selection, see Section 6, Dormers, Roof Lights, and Skylights, Section 7, Flashings – Penetrations and Intersections, and Section 9, List of Examples.

For further details, please consult DUKO (www.duko.dk), www.godetage.dk, www.membranerfa.dk, and TRÆ 67, Undertage (Roofing Underlayment) (Træinformation, 2013).

Furthermore, see installation guides and further information from product manufacturers.

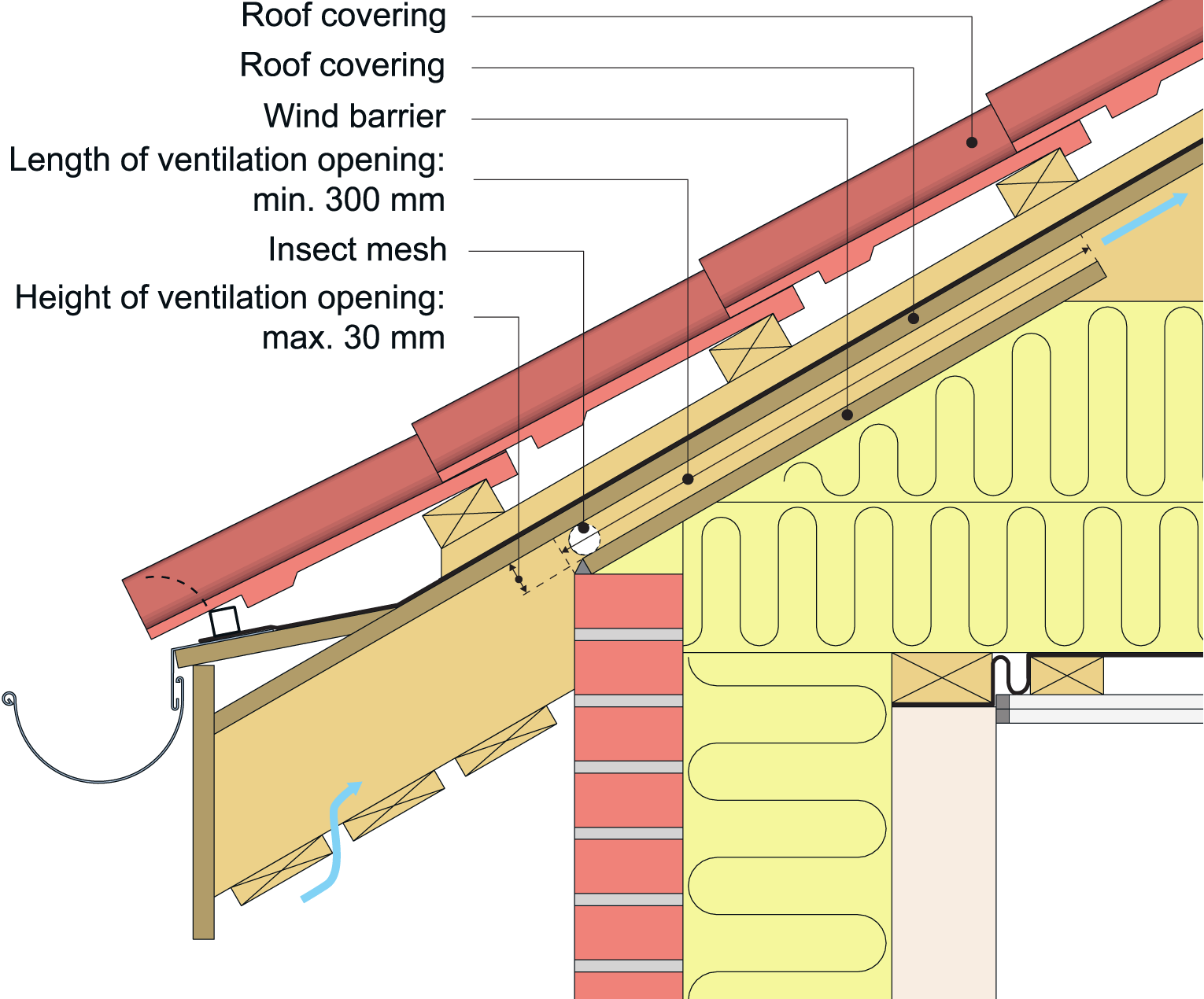

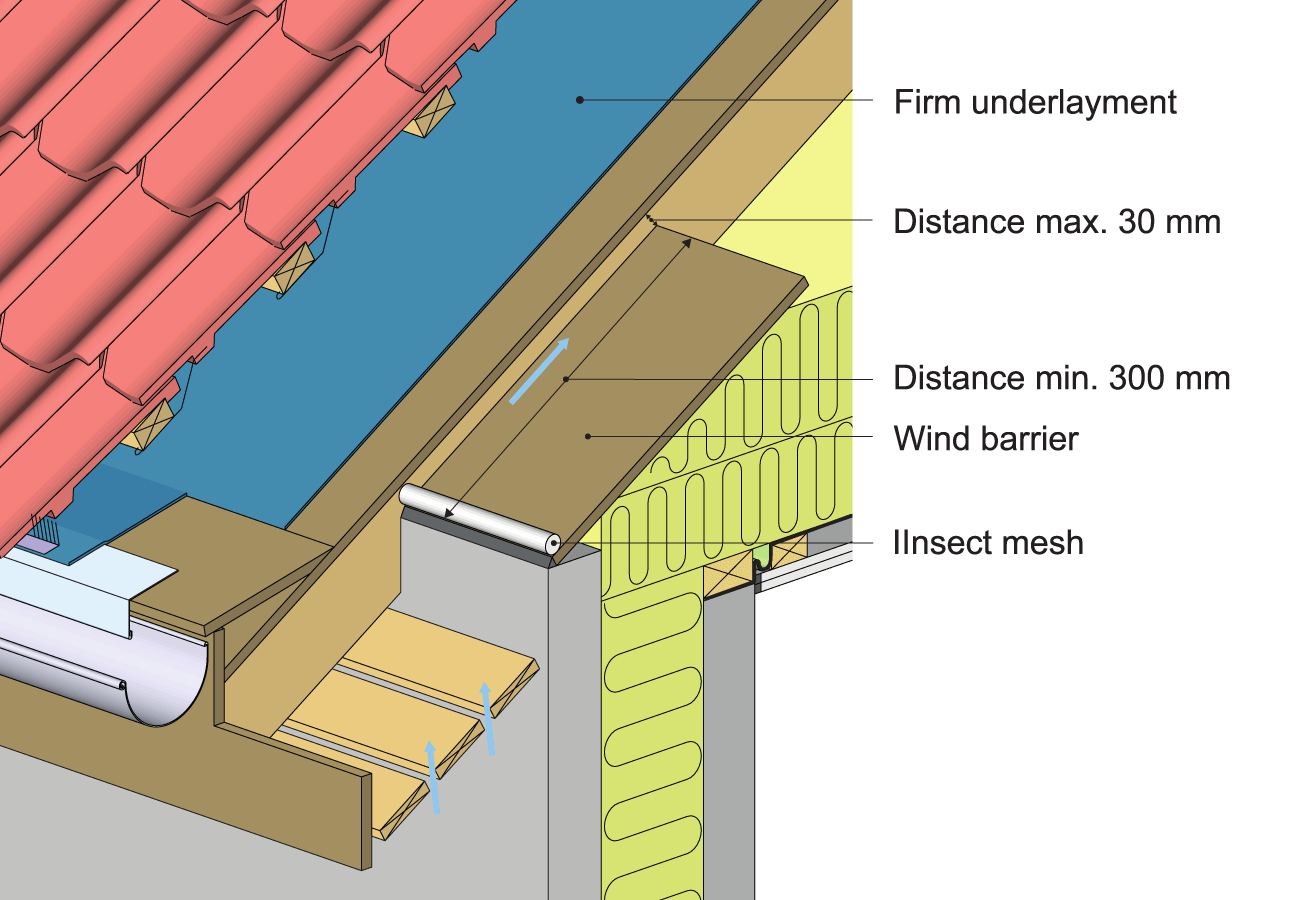

Fire-Safe Eaves with a Firm Underlayment

Figure 47. In multi-storey buildings, underlayment at eaves and gable ends must be protected against flame spread. To ensure that the roof structure meets fire safety regulations and is adequately vented, the space between wind barriers in the vent space must be min. 300 mm long and max. 30 mm high. There should be no eave vent spaces 1 metre from fire compartment walls (see Figure 48) (DBI Fire and Security, 2007.

Figure 48. An example of an eave assembly with firm underlayment and roofing membrane cladding. The figure shows a roof in a multi-storey building which is also subject to specific requirements regarding the form and proportions of vent openings to avoid the risk of flame spread. The insect mesh in this example is fitted to the vent opening but could also be fitted across the soffit boards. A plywood wind barrier will fix the thermal insulation material, preventing cold air from entering under the insulation (see Figure 47).

Roll-Material Underlayment at Eaves

Figure 49. Underlayment at eaves in a roof assembly with roll-material underlayment and vented loft space. When using insect mesh in the vent opening, the opening must be at least 30 mm high, as in this example. Alternatively, the insect mesh can be fitted across the soffit boards, as shown in Figure 50.

Figure 50. Underlayment at eaves in a roof assembly with roll-material underlayment and vented loft space. The vent opening must be at least 15 mm high when the insect mesh is fitted across the soffit boards as in this example.

Gable End with Overhang

Figure 51. Example of wood-fibre sheet underlayment details at a gable end with an overhang. Flashing has been added to the fascia to prevent water ingress behind the fascia.

Valley

Figure 52. Example of vented underlayment at a valley. The vent openings consist of roof vents in the underlayment just above the valley (see Section 7.2.4, Valleys).

Penetration

Figure 53. Positioning of roof vent in underlayment below a penetration (e.g., a roof light or chimney), to ensure effective ventilation, which would otherwise be blocked by the roof light. When using interlocking clay roof tiles, a vent tile must be placed near the roof vent.