9 LIST OF EXAMPLES

This section lists examples of typical roof assemblies, each including:

- Roof type with a description of the construction and accompanying drawings. Details include the assembly as a whole (e.g., vapour barrier, insulation, roofing underlayment, and roof covering).

- A review of typical materials used in the roof assembly. All descriptions structured to describe the roof assembly layer by layer seen from the outside.

- Examples are illustrated with drawings showing the relative position of the materials used.

- Roof assembly examples are supplemented by examples of how details are executed (see Section 7, Flashings – Penetrations and Intersections).

9.1 Vented Roofs

In vented roof assemblies, moisture is removed from the inside by ventilation between insulation and roofing underlayment or insulation and roof covering. If discontinuous roof coverings with roofing underlayment such as clay tiles are used, there must also be ventilation on the underside of the roof covering.

A precondition for an efficient vented roof is that moisture from the inside of the house is prevented from entering the roof assembly, typically by means of a vapour barrier, which must be both vapour-impermeable and airtight (preventing the upward flow of moist indoor air).

9.1.1 An example of a Vented Roof in a Single-Family Dwelling with Roofing Underlayment and Unutilised Loft Space

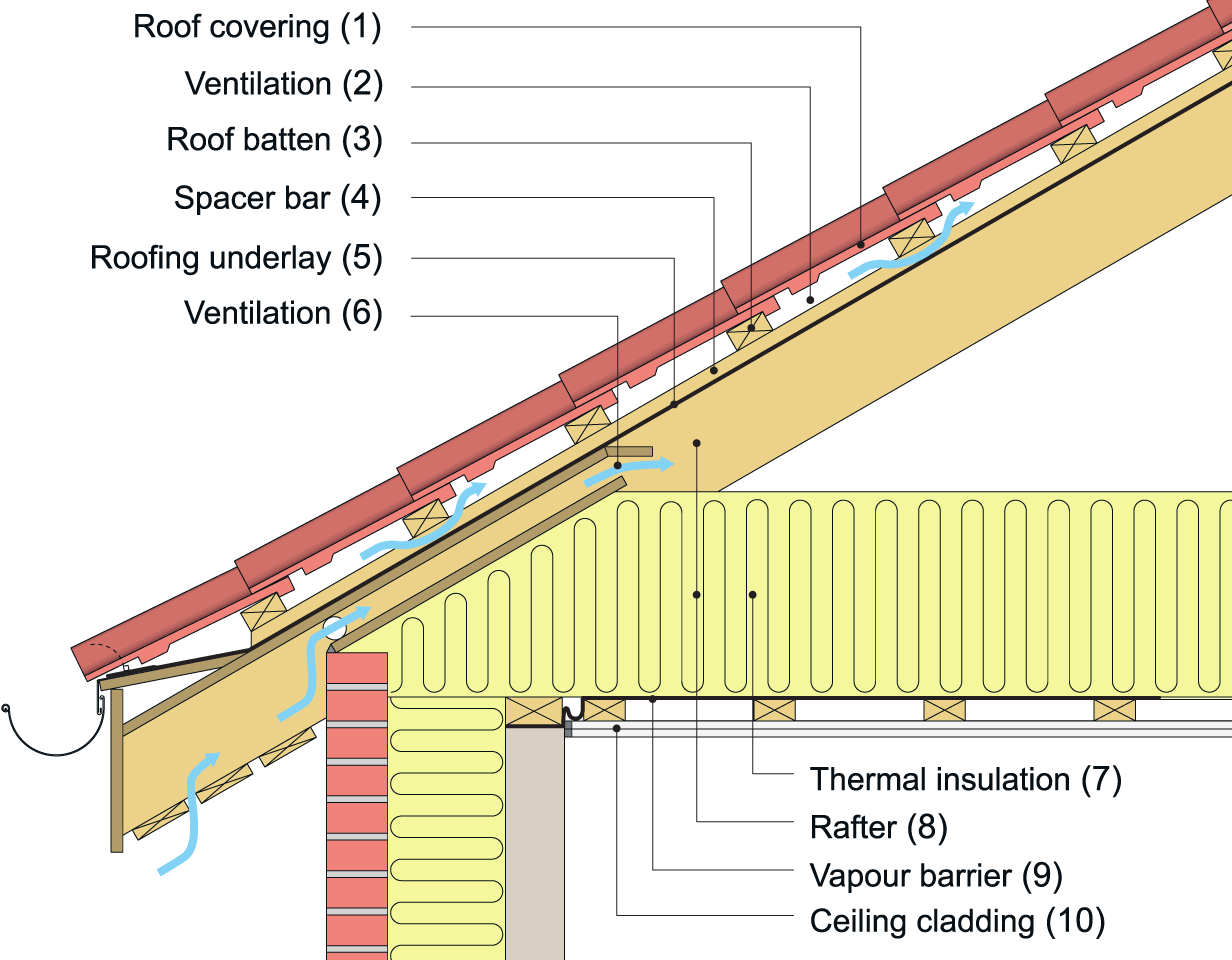

Figure 253. An example of a vented tiled roof with roofing underlayment in a single-family dwelling with vented unutilised loft space. The moist indoor air is prevented from penetrating the roof assembly by means of a tight vapour barrier. Any moisture that might penetrate from below or enter via the ventilation system during specific weather conditions is removed via ventilation between the thermal insulation and roofing underlayment.

- The roof covering (cf. Section 5, Roof Coverings) is shown as roof tiles in the drawing, but could also be slate, fibre-cement slate, or corrugated sheets. The roof covering could also be a roofing membrane. If that is the case, the following items 2–4 do not apply. For reasons of fire safety, the roof covering must be classed as BROOF(t2). This criterion is met by the types of roof covering listed. Please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire) (The Danish Transport, Construction and Housing Authority, 2018e).

- Ventilation between roof covering and roofing underlayment (cf. Section 2.3, Roof Ventilation). If roofing underlayment has been installed, ventilation must be established between roof covering and underlayment. The size of the vent openings is relative to the type of roof covering. Manufacturer’s instructions must be followed. For clay tiles, there will typically be a requirement for a specific vent opening size (e.g., 200 cm2 per linear metre at the eaves and ridge).

- Roof battens (cf. Section 2.6.1, Roof Battens). The roof covering is installed on roof battens unless the roof covering is a roofing membrane. A batten dimension of 38 × 73 mm is commonly used. This applies to a rafter spacing of up to 1000 mm, a batten spacing of max. 550 mm, and a roof covering of max. 60 kg/m². For large-scale rafters, a wider batten spacing, or heavy roof coverings, it may be necessary to use larger batten dimensions (cf. Section 2.6.1, Roof Battens) and Taglægter (Roof Battens) (Træinformation, 2011b).

- Spacer bars (cf. Section 3.1.2, Spacer Bars). Pressure-impregnated spacer bars are used with dimensions of min. 45 × 25 mm.

- Roofing underlayment (cf. Section 3, Roofing Underlayment), may be made of roll material, flexible sheets, or may be a firm underlayment (i.e., walk-proof decking with roll material laid on top). The roofing underlayment can be vapour-permeable or vapour-impermeable and must suit the roof covering, roof slope, underlayment accessibility, specific location of the house, and complexity of the roof. Roofing underlayment can be selected according to DUKO’s guidelines (www.duko.dk).

- Ventilation between roofing underlayment and thermal insulation (cf. Section 2.3, Roof Ventilation). The roof assembly must be vented via vent openings measuring min. 30 mm (including fitted insect mesh). The vent space between the insulation and the roofing underlayment must be min. 70 mm for roll material and flexible sheets and min. 45 mm for firm roofing underlayment. If vapour-permeable roofing underlayment is used in open loft spaces, apexes, or large crawl spaces (floor areas wider than 1 metre), modest ventilation is established using roof vents in the roofing underlayment top and bottom in every second set of roof trusses, for example.

- Thermal insulation (cf. Section 2.4, Heat Loss). The thickness of the thermal insulation layer is specified based on the energy calculation and the material’s thermal conductivity (λ-value). For assemblies with unutilised loft spaces, the lower min. 50 mm of the thermal insulation can be executed using min. material class D-s2,d2 [class B material]. The remaining part of the thermal insulation can (under certain conditions, such as if the insulation is flashed at the outermost 300 mm at eaves) be executed in insulation materials which, in fire-safety terms, are inferior to material class D-s2,d2 [class B material] (please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire) (The Danish Transport, Construction and Housing Authority, 2018e)).

- Rafters (cf. Section 2.6, Load-Bearing Capacity and Stability), are normally made of timber, but can also be made of steel. Dimensions are calculated via structural calculations, but geometric conditions resulting from requirements for thermal insulation thickness can also be a determining factor.

- The vapour barrier (cf. Section 2.1.2, Vapour Barriers in Roofs) is normally a roll material. Steps must be taken to ensure that the vapour barrier has tight joints and is connected to adjoining building parts with tight joints. The vapour barrier can be fixed to rafters or lathing using clamps positioned in a straight line, consecutively spaced out at approx. 100 mm. It is a good idea to place the vapour barrier so that it extends a little into the thermal insulation layer (max. 1/3 measured from the warm side), thereby protecting it from perforation and allowing installations such as power cables to be installed without perforating the vapour barrier. Please note the health and safety regulations concerning insulation below the vapour barrier.

- The ceiling is normally made from sheeting (e.g., a single or double layer of plasterboard installed with staggered joints, or wood panelling). For reasons of fire safety, the ceiling must be classed as min. cladding class K1 10 D-s2,d2 [class 2 cladding]. Any installations in the loft space must be protected against frost and must be accessible for inspection (e.g., via a trapdoor). The trapdoor must be air and vapour tight. Similarly, there are requirements for the thermal insulation capacity of the trapdoor (U-value ≤ 1.80) (BR18, § 257).

9.2 Unvented Roofs

In unvented roof assemblies with discontinuous roof coverings such as roof tiles or slate and a vapour-permeable roofing underlayment, indoor moisture is removed via diffusion through the roofing underlayment (see Section 3.2.2, Unvented Roofing Underlayment).

In unvented roof assemblies with continuous roof coverings, moisture can be removed via a moisture-adaptive vapour barrier which must fulfil certain conditions (see Section 2.1.2, Vapour Barriers in Roofs).

Unvented roofs can also be constructed as warm roofs (cf. Section 1.3, Warm and Cold Roofs).

9.2.1 An Example of an Unvented Couple Roof with Discontinuous Roof Covering for a Single-Family Dwelling

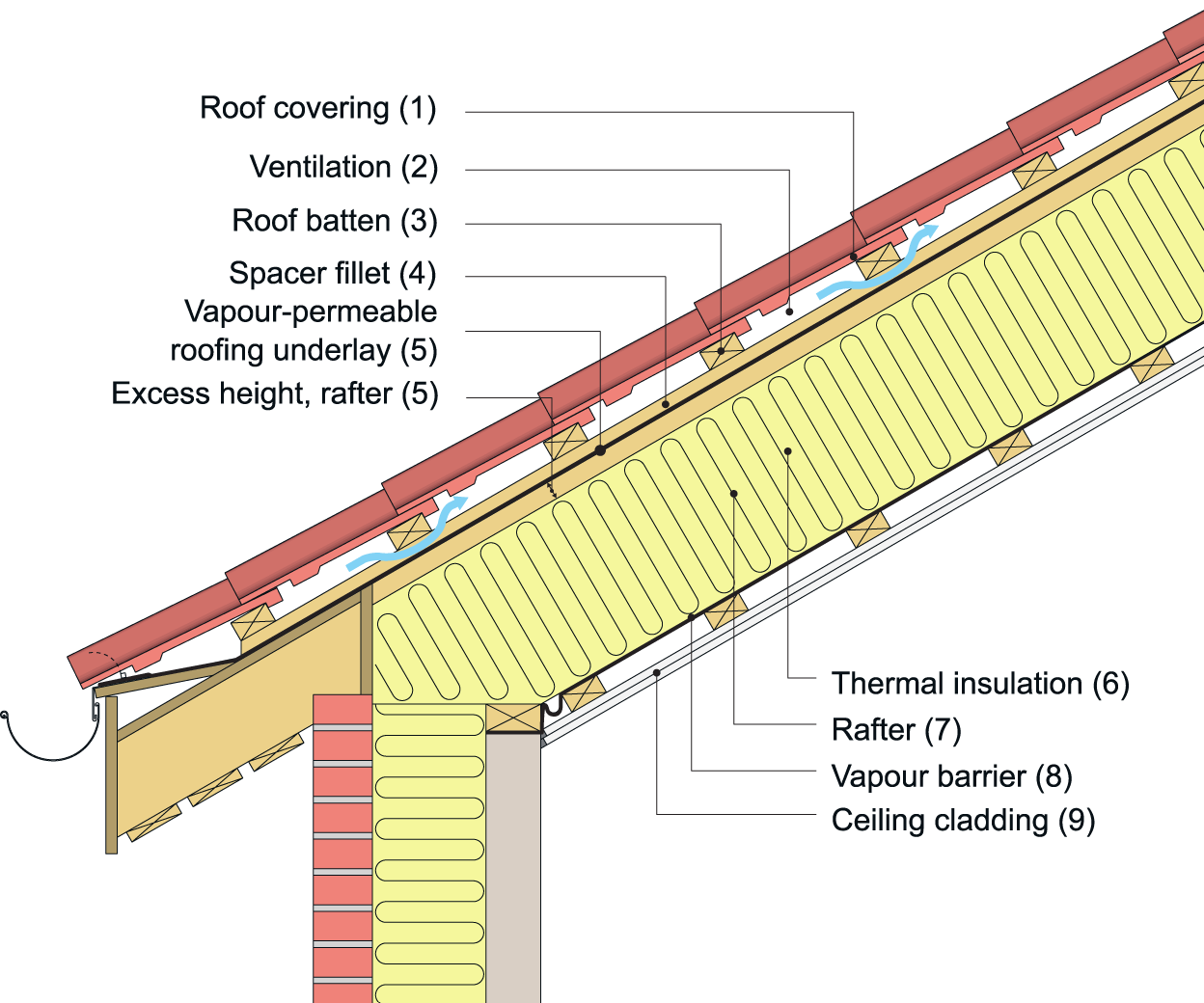

For roll-material roofing underlay, it should be noted that insulation materials are supplied with a thickness tolerance, meaning that the insulation may have excess height relative to the declared thickness. When designing rafter heights, allowances should be made for this excess height, or the insulation could be fixed with 2 mm wire per 300 mm, for example (Byg-Erfa, 2015b). This will prevent the roofing underlayment from bending upwards between rafters, allowing any water on the underlayment to penetrate at joints and nail holes above the rafters.

Figure 254. An example of an unvented couple roof with a tiled roof and vapour-permeable roofing underlayment in a single-family dwelling. The vapour barrier prevents moist indoor air from penetrating the roof assembly. Any moisture that might penetrate from below is removed by diffusion via the roofing underlayment and ventilation of the roof covering.

- The roof covering (cf. Section 5, Roof Coverings) is shown here as roof tiles, but could also be slate or fibre-cement sheets. For reasons of fire safety, the roof covering must be classed as BROOF(t2). This criterion is met by the types of roof covering listed. Please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire) (The Danish Transport, Construction and Housing Authority, 2018e).

- Ventilation between roof covering and roofing underlayment (cf. Section 2.3, Roof Ventilation). Ventilation must be established between roof covering and underlayment. Ventilation capacity is relative to roof covering type. Manufacturer’s instructions must be followed. Clay tiles will usually have to meet requirements for a specific vent opening size (e.g., 200 cm2 per linear metre at the eaves and ridge).

- Roof battens (cf. Section 2.6.1, Roof Battens). A batten dimension of 38 × 73 mm is commonly used. This applies to rafter spacing of up to 1000 mm, batten spacing of max. 550 mm, and roof covering of max. 60 kg/m².

- Spacer bars (cf. Section 3.1.2, Spacer Bars). Pressure-impregnated spacer bars are used with dimensions of min. 45 × 25 mm.

- Roofing underlayment (cf. Section 3, Roofing Underlayment). Roll material or flexible sheets are usually used for vapour-permeable roofing underlayment. The underlayment must be vapour-permeable and must match the roof covering, roof slope, location of the house, and complexity of the roof. If roll-material underlayment is installed, the insulation must be fixed, or the rafters must be designed to allow for the excess height of some thermal insulation materials of up to 15 mm per layer. This will prevent the roofing underlayment from bending upwards between rafters, which would allow any water on the underlayment to penetrate at joints above the rafters (Byg-Erfa, 2015b). Roofing underlayment can be selected according to DUKO’s guidelines (www.duko.dk). If vapour-permeable roofing underlayment is used in open loft spaces, apexes, or large crawl spaces (floor areas wider than 1 metre), modest ventilation is established, for example, by using roof vents in top and bottom of the roofing underlayment in every second set of roof trusses.

- Thermal insulation (cf. Section 2.4, Heat Loss). The thickness of the thermal insulation is specified based on the energy calculation and the material’s thermal conductivity (λ-value). For assemblies with unutilised loft spaces, the lower min. 50 mm of the thermal insulation can be made from material in min. class D-s2,d2 [class B material]. The remaining part of the thermal insulation can (under certain conditions, such as if the insulation is flashed) be made from insulation materials with an inferior fire-safety material class than D-s2,d2 [class B material] (please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire) (The Danish Transport, Construction and Housing Authority, 2018e)).

- Rafters (cf. Section 2.6, Load-Bearing Capacity and Stability) are normally made of timber, but can also be made of steel. Dimensions are calculated via structural calculations, but geometric conditions (e.g., requirements for thermal insulation) can also be a determining factor.

- The vapour barrier (cf. Section 2.1.2, Vapour Barriers in Roofs) are normally made from roll material. Steps must be taken to ensure that the vapour barrier has tight joints and is also connected to adjoining building parts with tight joints. The vapour barrier is fixed (e.g., to rafters or lathing) using clamps placed in a straight line, spaced consecutively at approx. 100 mm. It is advisable that the vapour barrier be positioned so that it extends marginally into the thermal insulation layer (max. 1/3 measured from the warm side for moisture load classes 1 and 2), protecting it from perforation and allowing installations (such as power cables) to be fitted without perforating the vapour barrier.

- The ceiling is normally made from sheeting material (e.g., a single or double layer of plasterboard) installed with staggered joints, or from wood panelling. For reasons of fire safety, the ceiling material class must be min. cladding class K1 10 D-s2,d2 [class 2 cladding] (see Section 2.5.2 Fire from the Inside). If there are installations in the loft space, these must be protected from frost and must. be accessible for inspection (e.g., via a trapdoor). The trapdoor must be air and vapour tight. Similarly, there are requirements for the thermal insulation capacity of the trapdoor (U-value ≤ 1.80) (BR18, § 257).

9.2.2 An example of an Unvented Roof with a Moisture-Adaptive Vapour Barrier

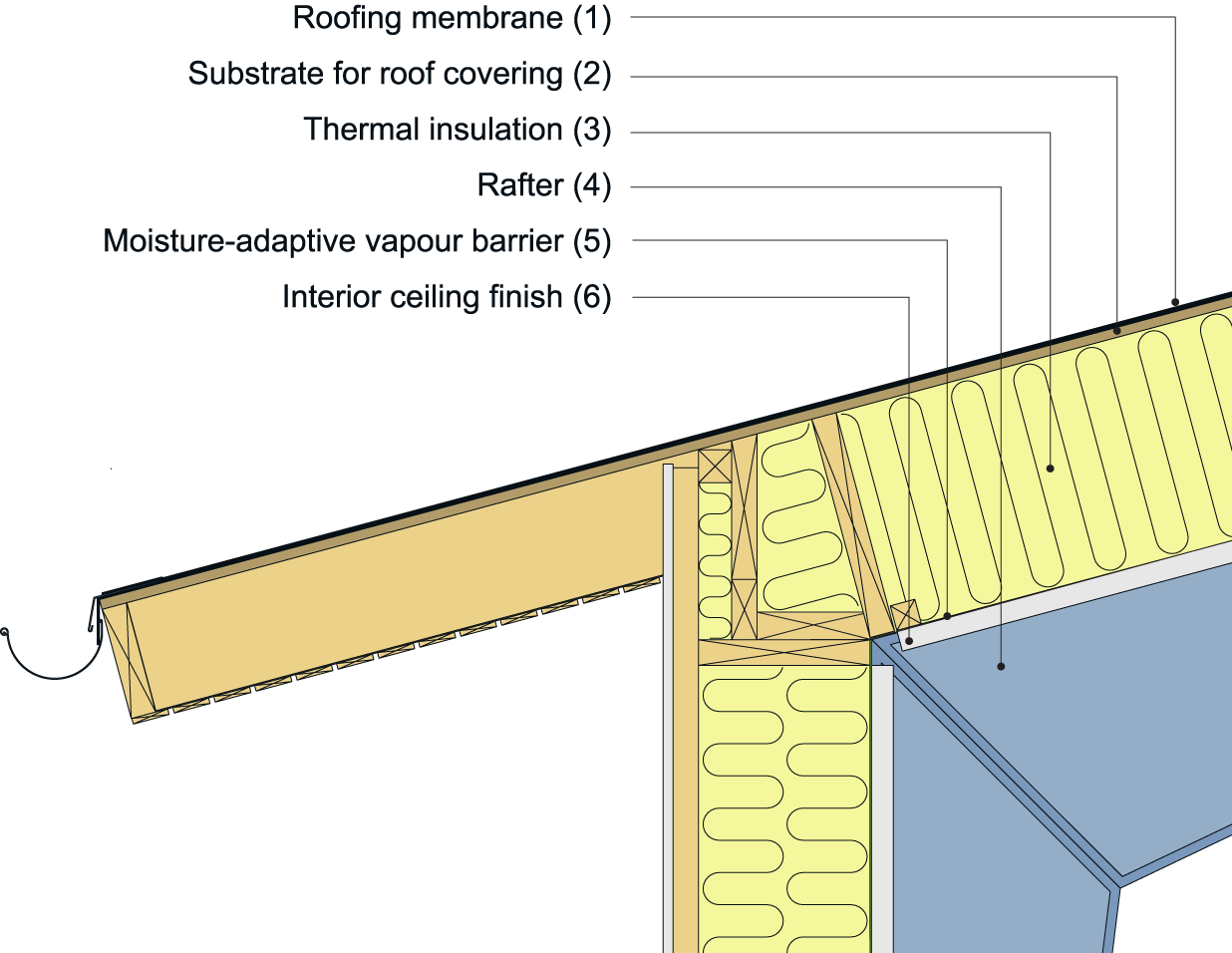

In unvented roofs with a continuous roof covering (such as membranes or zinc), a moisture-adaptive vapour barrier can be used. During the summer, it allows moisture to escape from the roof assembly through the loft space.

Moisture-adaptive vapour barrier is the term used for special vapour barriers whose diffusion resistance is dependent on the relative humidity (RH) of the surroundings. Moisture-adaptive vapour barriers are normally highly diffusion resistant at a low RH where they function as an ordinary vapour barrier (typically during winter). At a high RH, on the other hand, their diffusion resistance is low (i.e., they no longer function as vapour barriers) and they allow moisture to pass through.

A precondition for using these materials is that the roof is warmed by the sun during summer. Under these conditions moisture from diffusion is pressed down towards and through the vapour barrier (see Section 2.1.2, Vapour Barriers in Roofs). Therefore, this type of roof must not be exposed to long periods of shade such as that case by north-facing parts of pitched roofs with high slopes, adjacent taller buildings, parapet walls, tall trees, or solar panels.

This solution is regarded as less moisture-proof and should therefore not be used in moisture load class 3 or higher.

Figure 255. An example of unvented roof assembly with a moisture-adaptive vapour barrier and a continuous roof covering (e.g., in a sports hall). Moisture penetrating the roof assembly during winter is removed when the sun heats the roof covering during summer. In these conditions, moisture is transported down to the vapour barrier where it is able to diffuse into the space below. The ceiling cladding must be vapour-permeable.

- The roof covering (see Section 5, Roof Coverings) is normally a watertight roofing membrane, such as bituminous felt or PVC foil. For reasons of fire safety, the roof covering must be classed as BROOF(t2). Please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire) (The Danish Transport, Construction and Housing Authority, 2018e).

- Substrate for roof covering (see Section 5.7.4, Constructing a Membrane Roof) is typically made of a substrate of wood boards or timber-based sheets, including the upper side of composite roofing slabs.

- Thermal insulation (see Section 2.4, Heat Loss). The quantity of thermal insulation is specified based on the energy performance requirement of the building and the material’s thermal conductivity (λ-value). Insulation materials which are not a minimum material class of D-s2,d2 [class B material] can only be used under certain conditions (please see Bygningsreglementets vejledning til kapitel 5 – brand (Guidelines in the Building Regulations for Chapter 5 – Fire)) (The Danish Transport, Construction and Housing Authority, 2018e). The thermal insulation must completely fill the cavity space between vapour barrier and substrate.

- Rafters (cf. Section 2.6, Load-Bearing Capacity and Stability) are normally made from steel, but can also be made from glue-laminated wood (gluelam). Dimensions are calculated using structural calculations, but geometric conditions resulting from requirements for insulation can also be a determining factor.

- Moisture-adaptive vapour barrier (cf. Section 2.1.2, Vapour Barriers in Roofs) is a roll material. Steps must be taken to ensure that the vapour barrier has tight joints and is also connected to adjoining building parts with tight joints. The vapour barrier is fixed (e.g., to rafters or lathing) using clamps placed in a straight line which are consecutively spaced approx. 100 mm from one another (see SBi Guidelines 224, Moisture in Buildings) (Brandt, 2013). When dry, the vapour barrier should have a Z-value of min. 50 GPa s m2/kg, unless it can be documented (by calculation) that a lower value is safe.

- The ceiling often consists of cement-bonded wood wool sheets (as shown on the drawing) or of a single or double layer of plasterboard installed with staggered joints. For reasons of fire safety, the ceiling must be classed as min. cladding class K1 10 D-s2,d2 [class 2 cladding] (see 2.5.2 Fire from the Inside). To exploit the moisture-adaptive properties of the vapour barrier, the surface treatment must be vapour-permeable.

Major risks of leakages or reduced drainage are likely to occur in roof details (e.g., intersections, hips, channels, and penetrations). Special attention is therefore required in both the design and execution phase.

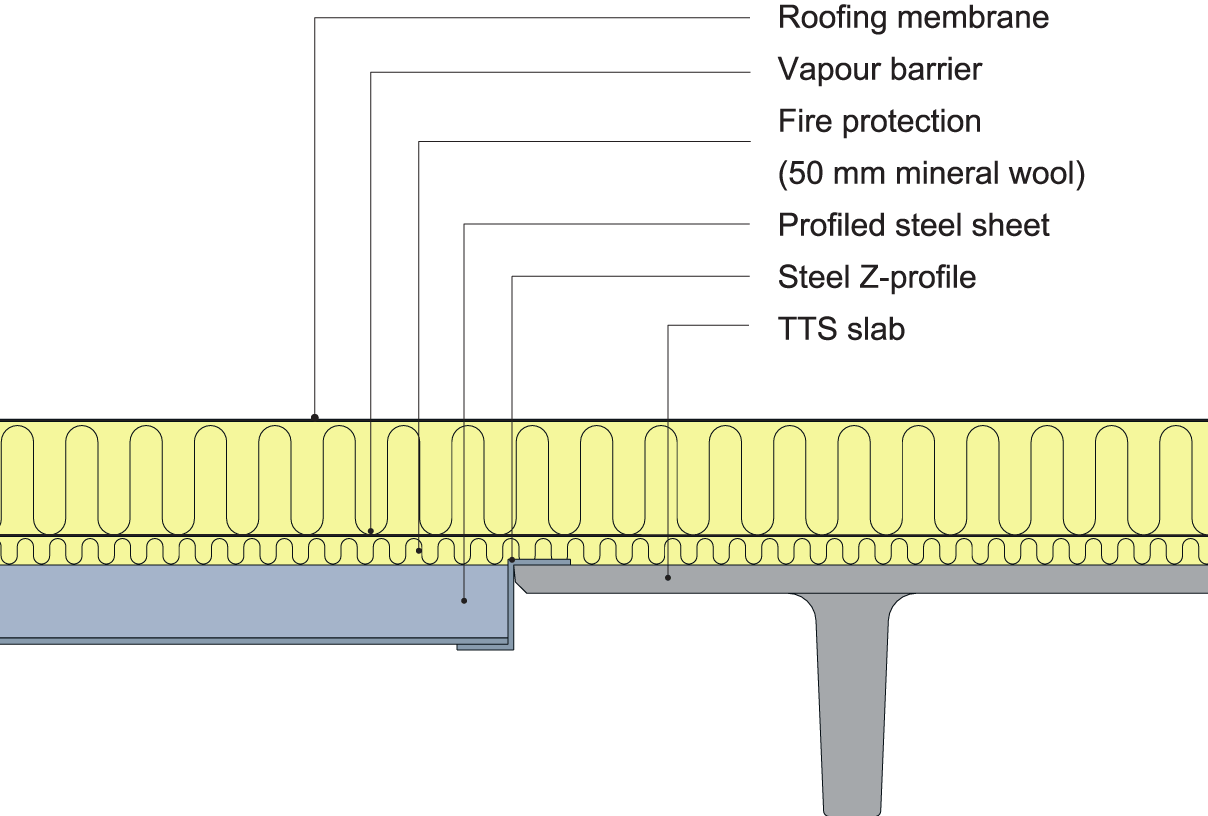

9.2.3 An example of an Industrial Roof Design

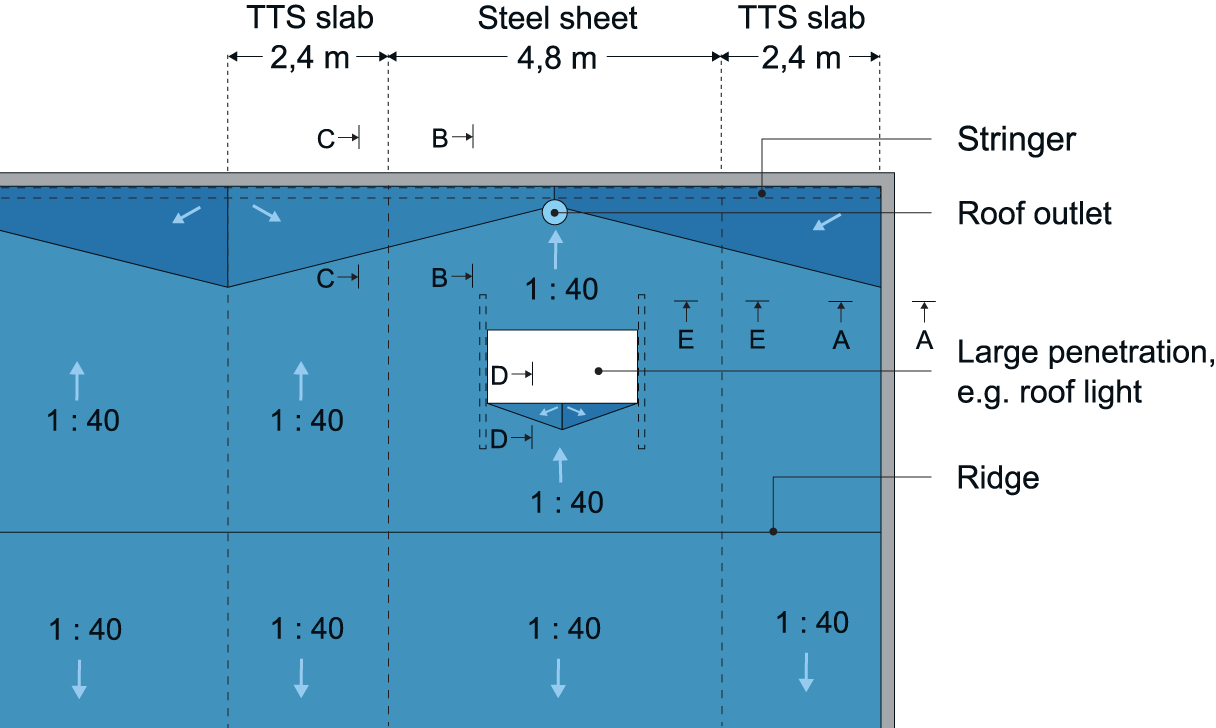

A typical industrial roof consists of TTS concrete slabs with integral falls of 1:40.

The 2.4-metre-wide slabs (TTS slabs) are laid with a spacing of 4.8 metres. Profiled steel sheets are laid between the TTS slabs, supported by a Z-profile on the edge of the concrete top plate of the TTS slabs. The roof functions as a shear-wall construction which stabilised the building. The shear forces are transferred from TTS slab to steel sheets via a sheet-metal profile screwed to the steel sheets and welded to embedded steel sheets in the TTS slab.

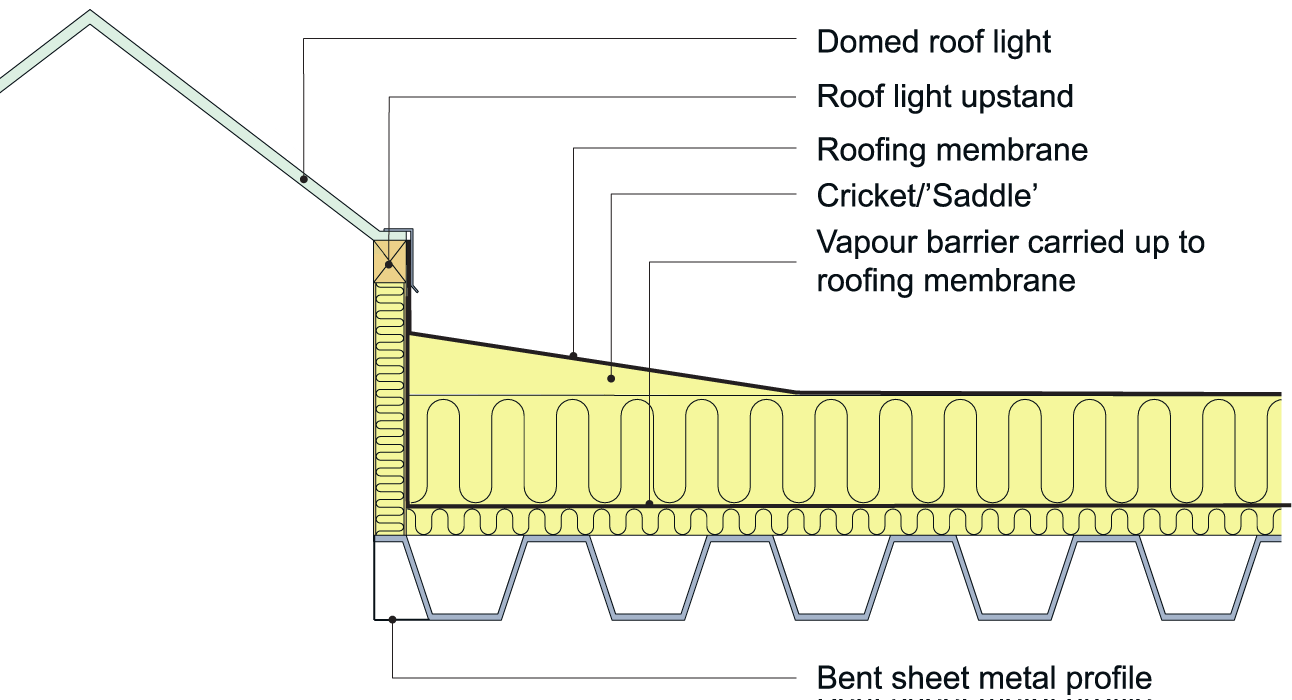

Figure 256. An example assembly featuring a roof outlet on industrial roof, placed near the facade at max. 14.4 metres and max. 7.2 metres from gable end. Crickets have been placed between the roof outlets which must slope towards the outlets along the facade. Behind large-scale penetrations, ’saddles’ or back-pan flashings are placed to divert rainwater away from the intersection and around the penetration. The letters on the drawing refer to basic sectional drawings in the following Figures 257–261.

Figure 257. Section E-E: TTS-slab roof with intermediate spans of profiled steel sheets, supported by a Z-profile on the edge of the TTS slabs’ concrete top plate.

Figure 258. Section C-C: An example of how stringer forces from crosswinds are absorbed in a continuous UNP steel profile along the facade.

- Stringer forces from crosswinds are absorbed in a continuous steel profile along the facade. The steel profile is fixed to both the TTS-slabs and the profiled steel sheets.

Figure 259. Section B-B: If the vapour barrier is flammable, it must be protected by 2 × 25 mm non-flammable insulation such as mineral wool, laid on the steel sheets.

- If the vapour barrier (cf. Section 2.1.2, Vapour Barriers in Roofs) is flammable, it must be protected (e.g., by 2 × 25 mm mineral wool laid across the steel sheets). No protection is required for the vapour barrier on the TTS slabs, but to ensure an level plane, 50 mm mineral wool is usually also laid across the TTS slabs as well.

Figure 260. Section D-D: Crickets (saddles) are installed behind large-scale penetrations (such as roof lights) to divert rainwater away from the intersection and around the penetration.

- Roof lights (cf. Section 6.1, Roof Lights for Flat Roofs), are placed in sections with profiled steel sheets, alternating with steel profiles placed in a crosswise direction. Behind the roof lights, crickets are installed (saddles) to divert rainwater away from the intersection and round the roof light.

Figure 261. Section A-A: The TTS slabs must be able to move in relation to the gable end (e.g., using specialist fixtures (the so-called ‘halfeneisen’)). This must also be facilitated in the roof covering (e.g., using extra-large chamfer strips which will allow movement).

- TTS slabs along gable ends are prone to deflection from snow load and it is therefore necessary to allow the TTS slabs to move in relation to the gable end using fixtures (such as the so-called ‘halfeneisen’). This must also be facilitated in the roof covering (e.g., using extra-large chamfer strips which will allow movement).

- Falls on TTS slabs are typically 1:40. Roof outlets are placed near the facade at max. 14.4 metres and max. 7.2 metres from the gable end. Crickets have been placed between the roof outlets along the facade, which must slope towards the outlets.

9.3 Eaves and Ridges

In vented roof assemblies, steps must be taken at eaves and ridges to ensure that:

- Vent openings are sufficiently large

- Ingress of driving rain and drifting snow via the vent space is mitigated

- Ingress of birds and insects via the vent space is mitigated

- Water from roofing underlayment is discharged to the gutter

- Fire spread via vent spaces is prevented

The following are examples showing how these functions are secured.

The examples are vented roof assemblies but these techniques can also be applied to unvented roof assemblies.

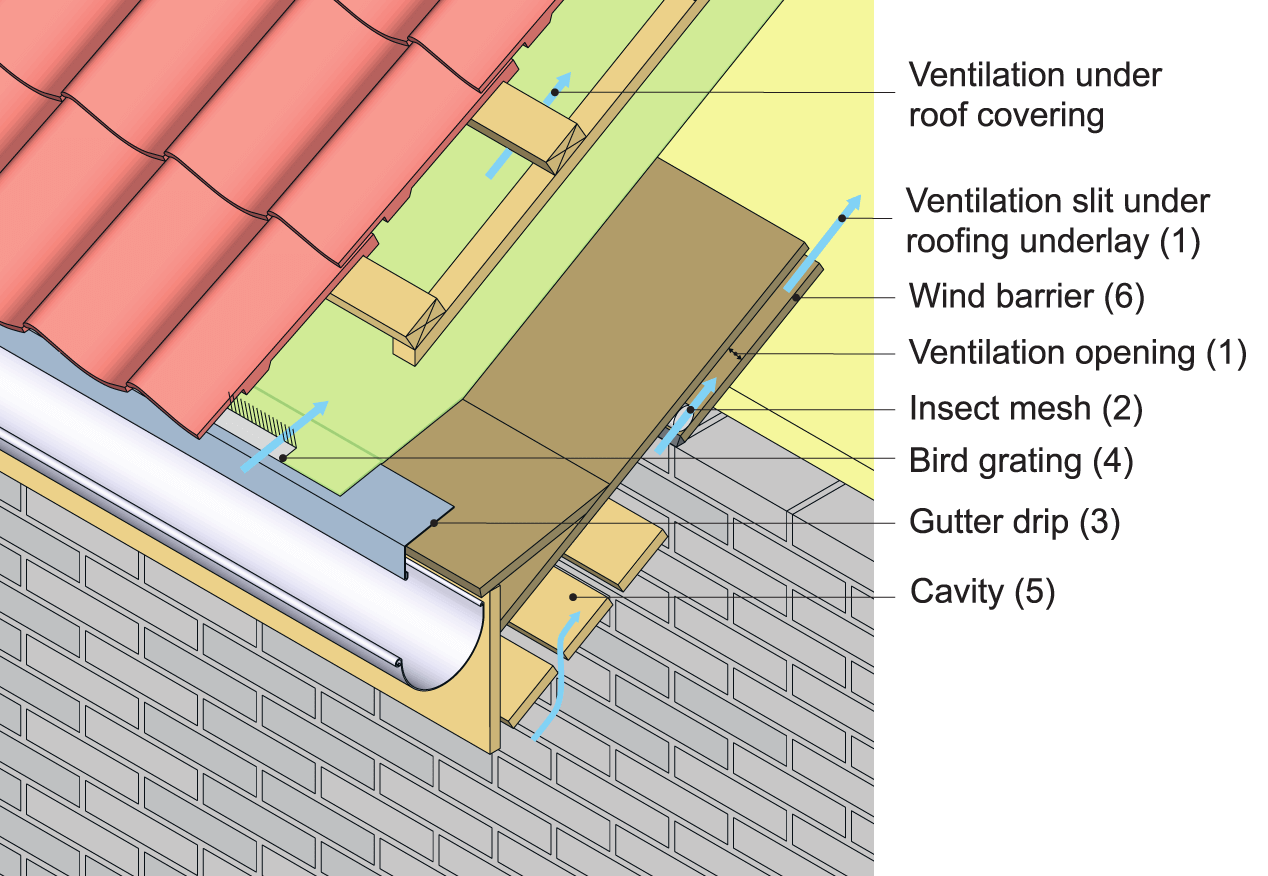

9.3.1 An example Eave Design for a Single-Family Dwelling

Figure 262. An example of eave detail in a vented roof assembly with a tiled roof covering and roofing underlayment carried out into the gutter. The drawing shows a construction suitable for preventing fire-spread.

- Vent openings and vent spaces ensure that the roof is vented, which will normally be achieved with a vent opening of 30 mm (including insect mesh). The gap must be min. 45 mm for firm roofing underlayment and min. 70 mm for roofing underlayment of roll material or flexible sheets (see Section 2.3, Roof Ventilation). For integrated single-family dwellings where the thermal insulation is inferior to material class D-s2,d2, requirements for the prevention of fire-spread can be met by ensuring that the vent opening is max. 30 mm high and min. 300 mm long. The sheets delimiting the vent opening must be min. cladding class K1 10 D-s2,d2 [class B cladding], such as structural plywood (type EN 636-2).

- The insect mesh/snow guard pipe prevents the ingress of insects, birds, and drifting snow. If the insect mesh is placed in the vent opening, the size of the opening must be min. 30 mm to ensure adequate ventilation. The insect mesh can also be used on top of the soffit boards, in which case the size of the vent opening can be reduced to 15 mm.

- Cleat edge flashing. The roofing underlayment is finished in a cleat edge flashing (which is bonded together). This ensures that water is discharged from the roofing underlayment directly into the gutter.

- Bird grating (air grating) ensures that the underside of the roof tiles is adequately vented while also barring the ingress of birds into the structure.

- Cavity space above soffit boards. If ventilation is achieved via cavity spaces above soffit boards, the velocity of drifting snow will be reduced and the majority will settle on the soffit boards rather than getting into the roof structure.

- Wind barrier. The wind barrier ensures that the insulation will not block the vent opening. It must be joined to the facade front wall in a tight joint to prevent cold air from blowing in under the insulation (on the warm side)

9.3.2 An example of a Ridge Design for a Mono-Pitch Roof Slope

Figure 263. An example of a ridge design in a vented mono-pitch couple roof. The example shows vented roofing underlayment and a tiled roof covering. Ridge ventilation is achieved via roof vents in the roofing underlayment and ventilation via vent tiles in the roof covering.

- The vent space between roofing underlayment and thermal insulation will ensure effective ventilation. The gap height must be min. 45 mm for firm roofing underlayment and min. 70 mm for roll-material underlayment (see Section 2.3, Roof Ventilation).

- Roof vents fitted in the roofing underlayment are used to achieve ridge ventilation. The size of the vents is selected according to specifications in Section 2.3, Roof Ventilation.

- Vent openings in the roof covering. To ensure that moisture escaping via the roof vents can be removed, vent tiles (cowls, or similar elements, are fitted depending on the roof covering). Roof vents and vent tiles are staggered relative to one another to reduce the ingress of drifting snow.

9.4 Examples of Warm and Cold Crawl-Space Design

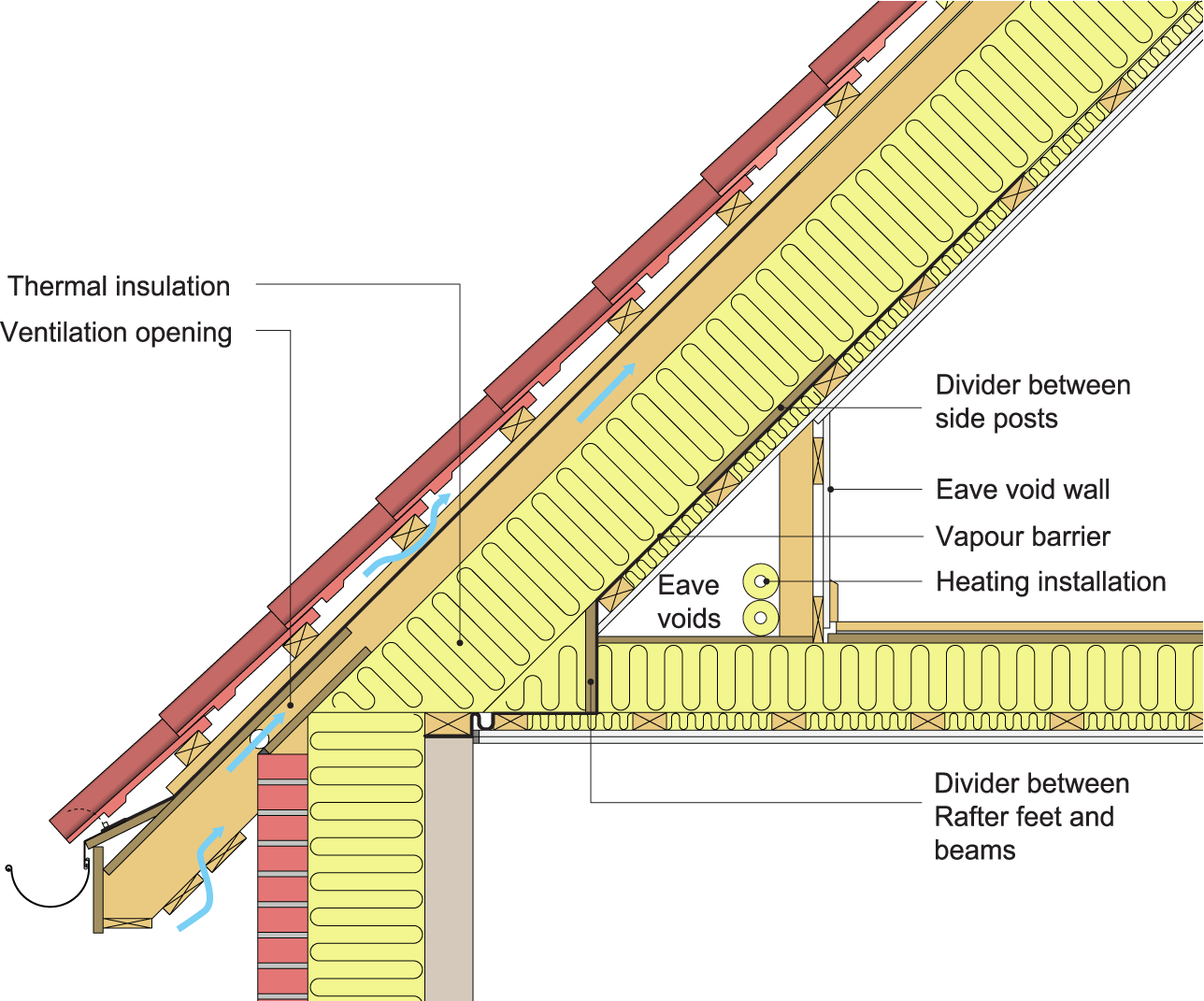

In attic-trussed buildings with a utilised top storey, there is normally a crawl space at the eave level. The crawl space can be either warm (i.e., the thermal insulation and vapour barrier ‘follow’ the roof level, so that the crawl space will be inside the climate envelope), or it can be cold (i.e. the thermal insulation and vapour barrier follow the internal vertical (crawl-space) wall and the floor, so that the crawl space is outside the insulation or climate envelope).

9.4.1 An Example of a Warm Crawl-Space Design

In warm crawl spaces, any installation placed there will be frost-free. The crawl-space wall can be built as an ordinary stud wall with interior ceiling finish (e.g., a double layer of plasterboard). No vapour barrier is required for the crawl-space wall and there is no need for the trapdoor to this space to fit tightly, since the crawl is space is not part of the climate envelope.

The thermal insulation along the roof must be carried right down to the eaves and the roof vapour barrier must be joined tightly to the eaves or external wall (and any vapour barrier, if applicable). A continuous airtight enclosure must be established.

If there are installations in the crawl space, these must be accessible for inspection (e.g., via a trapdoor).

If the cladding on the sloping wall is not carried down to the eaves level in the crawl space, the vertical crawl-space wall must be made fire safe (e.g., with a cladding class K1 10 D-s2,d2 [class 2 cladding ] with min. 50 mm insulation of min. material class D-s2,d2 [class B material]) (The Danish Transport, Construction and Housing Authority, 2018e).

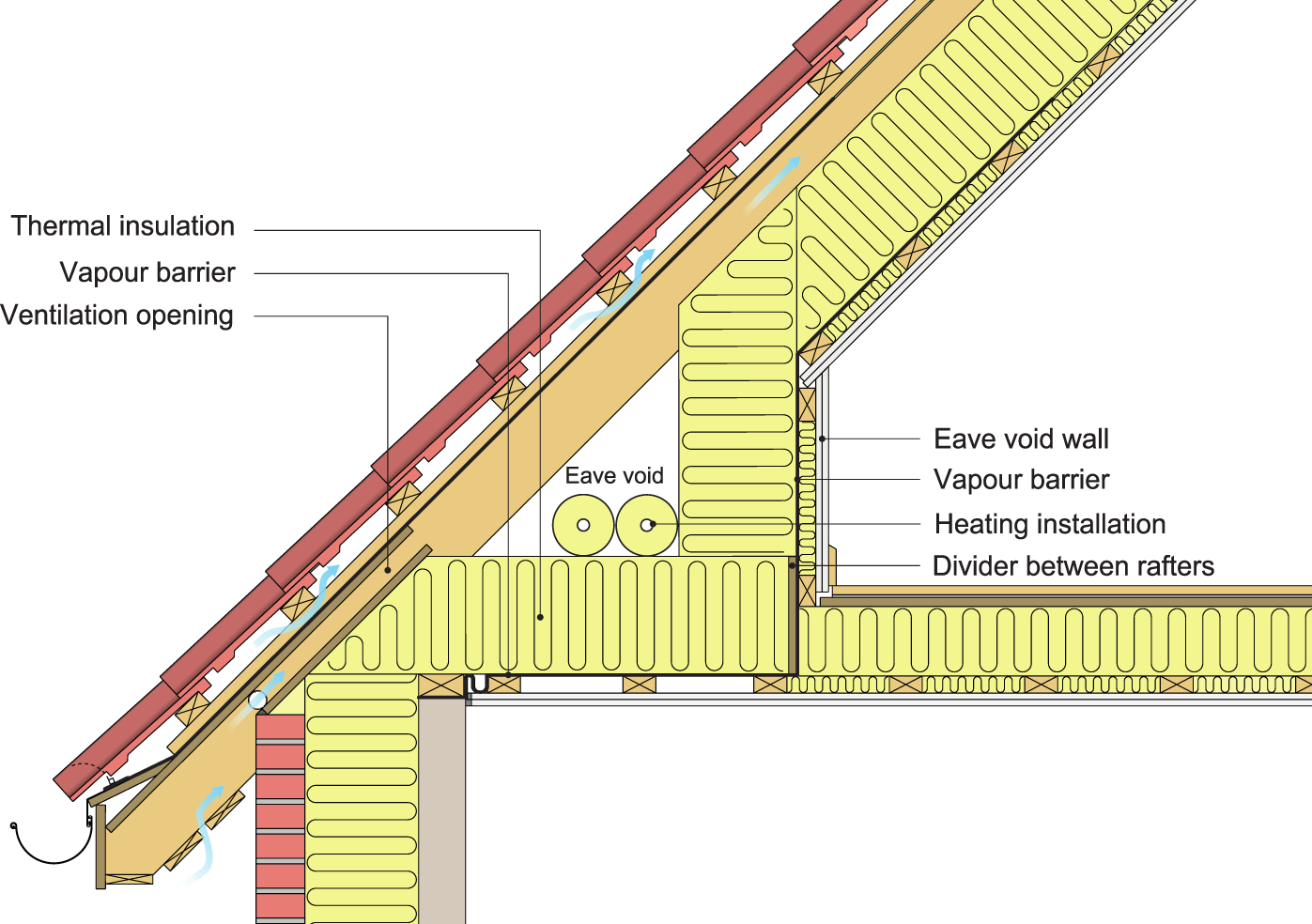

Figure 264. An example of the construction of a vented attic-trussed roof with a warm crawl space. The thermal insulation and vapour barrier ‘follow’ the roof out to the thermal insulation in the exterior wall. The roof vapour barrier in the example is joined to the wall plate above the back wall via a divider inserted between the floor joists or beams (see Figure 266).

9.4.2 An Example of a Cold Crawl-Space Design

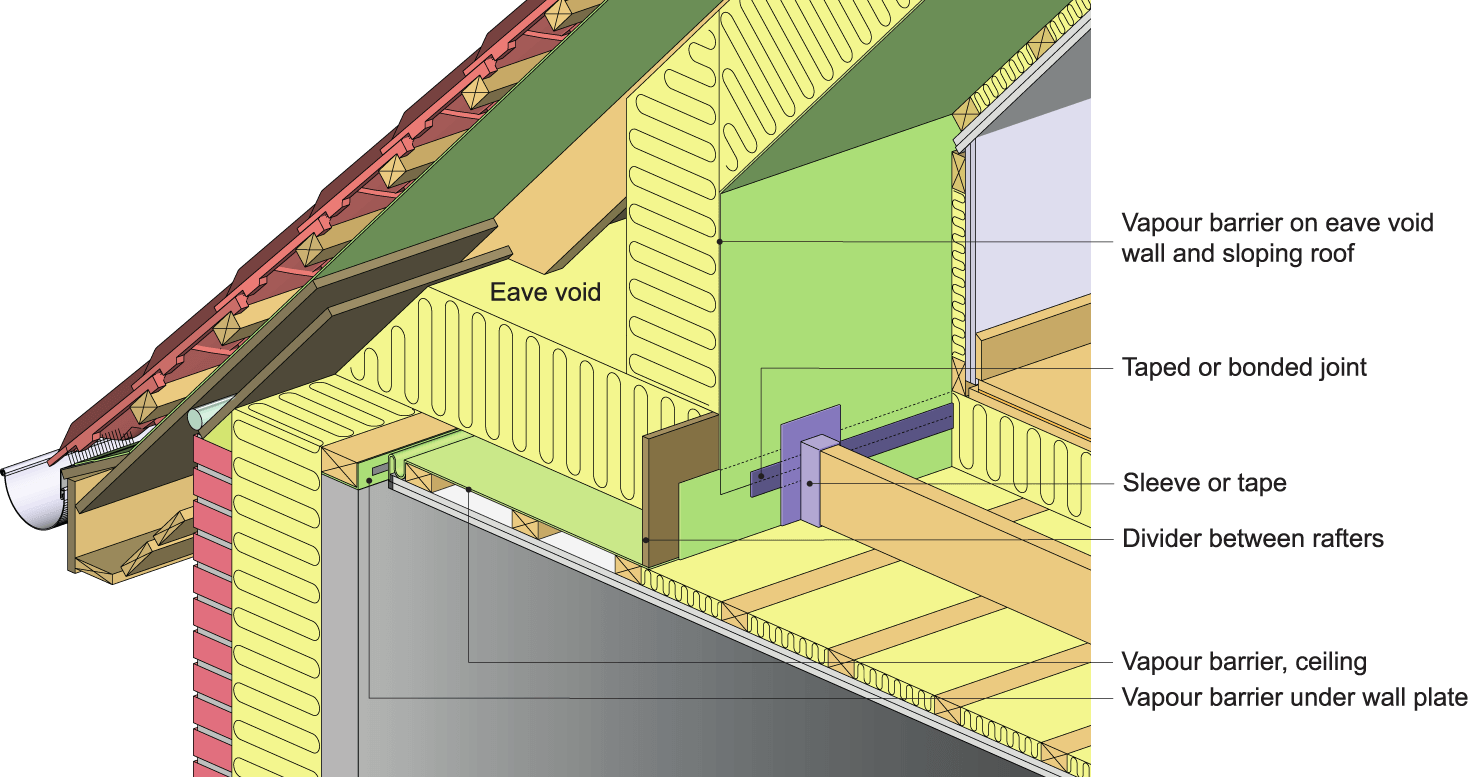

The vapour barrier in the ceiling below the crawl space floor is joined in a tight joint to the back wall and to the vertical vapour barrier in the crawl-space wall (e.g., the latter is joined across the divider inserted between the joists). In a cold crawl space, any installations placed in the crawl space must be protected from frost damage and water pipes must be thermally insulated.

In unvented roofs with a vapour-permeable roofing underlayment, modest ventilation must be established in crawl spaces with floor areas wider than 1 metre (e.g., via roof vents placed in the roofing underlayment top and bottom in every second set of roof trusses) because the forward pressure which influences the diffusion is poor in this area (Brandt, 2013).

If there are installations in the crawl space, these must be accessible for inspection (e.g., via a trapdoor). The trapdoor is part of the airtight enclosure in the climate envelope, and it must therefore be both air and vapour tight. There are also requirements for the thermal insulation capacity of the trapdoor (U-value ≤ 1.80) (BR18, § 257).

Figure 265. An example of the construction of a vented roof with a cold crawl space. To achieve a continuous airtight enclosure or vapour barrier, a divider has been placed between rafters or beams in the floor. The divider must fit tightly to rafters (e.g., by sealing or taping the joints). The vapour barrier from the ceiling and the vertical vapour barrier on the crawl-space wall are joined tightly across the divider (see Figure 266). The vapour barrier in the loft is joined tightly with the back wall. Any installations in the crawl space must be protected from frost damage.

Figure 266. An example of how to join the vapour barrier when constructing an attic-trussed roof with a cold crawl space. Between the rafters or beams in the floor, a divider has been placed in a tight fit against the rafter. Lengths of the horizontal vapour barrier from the crawl-space floor or ceiling and the vertical vapour barrier from the crawl-space wall are joined tightly across the divider.