6 DORMERS, ROOF LIGHTS, AND SKYLIGHTS

In this section, issues concerning dormers, roof lights, and skylights are outlined with special emphasis on interfaces with different types of roof coverings. ’Roof lights’ are used in this section as a collective term for roof lights for pitched roofs and domed roof lights for flat roofs. For small, simple roof lights, the term ’skylight’ is often used.

Roof lights and dormers are often used because they contribute to making the living space below more useful and comfortable by allowing daylight in.

Special rules apply concerning adequate ventilation around penetrations such as dormers, roof lights, and skylights (see Section 2.3.2, General Ventilation Guidelines.

Applicable Standards

Roof lights of plastic must be CE-labelled according to DS/EN 1873, Prefabricated accessories for roofing – Individual roof lights of plastics – Product specification and test methods (Danish Standards, 2014).

6.1 Roof Lights for Flat Roofs

6.1.1 Types of Roof Lights for Flat Roofs

Several different types of roof light are available for flat roofs:

- Domed acrylic or polycarbonate roof lights

- Flat-glass or arched roof lights

- Multi-pane roof light units

- Pyramids

- Roof lanterns

In the past (until the mid-1980s) flanged roof lights were very common. These involve a significant risk of leakage between the flange and roof covering due to poor adhesion between roof covering and flange. If such a roof is scheduled for renovation, flanged roof lights should be replaced with a different type. Flanged roof lights still exist in the form of circular roof lights and these should be placed on an upstand, bringing them approx. 45 mm above the roof surface.

Within the food industry, special veterinary roof lights are normally used with smooth surfaces for easy cleaning.

Roof light development is an ongoing process where energy-efficient glazing is used instead of, or in combination with, domes or plastic channel sheeting. These structures provide far better U-values than previous iterations (see Figure 181).

Figure 181. Vertical basic diagram showing the installation of plastic-domed roof light combined with energy-efficient glass in a warm roof assembly.

Roof Lights for Smoke Ventilation

Roof lights are often used for smoke ventilation in flat-roof buildings (e.g., industrial buildings). The roof lights are required to open automatically in the event of fire.

Notice that the effective area for smoke ventilation (aerodynamic free area) is smaller than the ‘geometric’ opening of the roof light (typically approx. 60%). The effective area is determined through testing. Roof lights for smoke ventilation must be CE-labelled according to DS/EN 12101-2 (Danish Standards, 2017). Several designs exist, including windows with hinged openings (these normally have a large opening angle of 140 ° for example) (see Figure 182) and windows which slide horizontally to one side.

Figure 182. An example of a roof light with an automatic opening in the event of fire. Fixtures must be designed to resist the existing wind suction on the roof. For hinged roof lights, the opening angle will usually be large (e.g., 140 °, as shown).

6.1.2 Installing Roof Lights in Flat Roofs

Roof lights for flat roofs are placed on an upstand flashed with a roofing membrane at the roof intersection.

Leakages in roof lights typically occur by roof light flashings. However, moisture problems may also occur on the inside due to condensate forming on the dome or side casing/upstand. These problems may be caused by adverse behaviour by occupants as well as a poor U-value in the upstand.

Roof light upstands must be thermally insulated to minimise thermal bridging. The upstand factors into the U-value of the entire roof light (see Figure 183). The remaining elements factor into the linear thermal transmittance from the installation. Please note that the U-value of roof lights will usually be higher than that of the surrounding roof. This means that, for roofs with many roof lights, heat loss via the roof lights may equal that of the remaining roof area.

Detailed descriptions of energy requirements for integral roof lights in flat roofs are given in Section 2.4.1, Building Regulations – Energy Provisions.

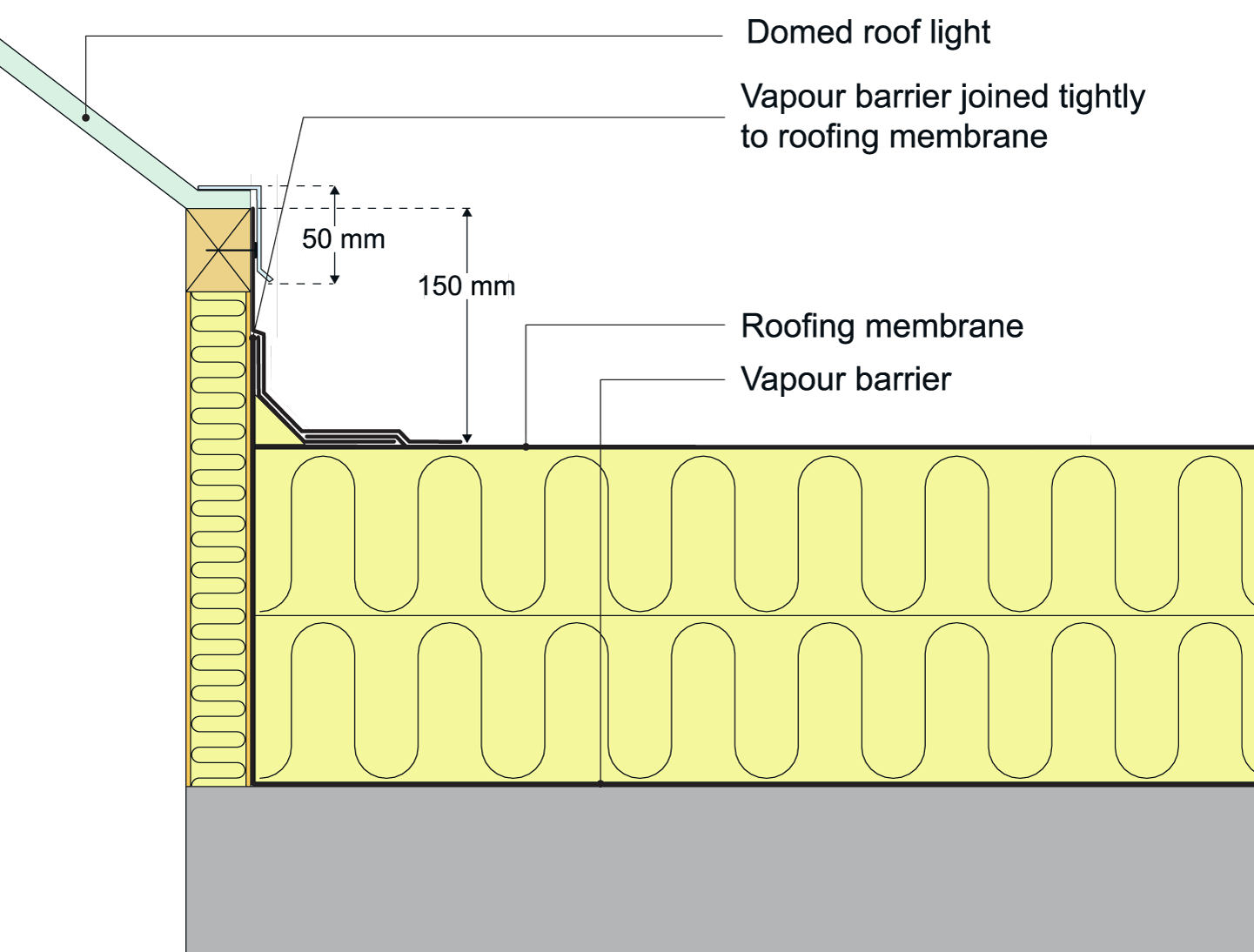

The vapour barrier around roof lights in flat warm roofs is flashed at vapour-barrier level with the roofing membrane.

It is vital that the roofing membrane is fixed to the roof light by an edging profile or by nailing to prevent it from sliding down.

Roof lights constitute a penetration of the roof and a sufficient flashing height is important, normally min. 150 mm. For extensive green roofs, flashing should be higher, typically 200 mm, because the growth layer will often expand slightly over time (see Section 5.11, Green Roofs).

If roof lights are positioned across falls and are more than 1 metre wide, rainwater is discharged behind them with back-pan flashing or a ‘saddle’ (see Figure 184 and Section 5.7.3, Roof Slope for Membrane Roofs). In falls away from the roof light due to this ‘saddle’, a flashing height of 100 mm is acceptable.

Examples of roof lights integrated into warm roofs are shown in Figures 185 and 186.

Figure 183. Terms for the relevant elements that form part of a dome roof light installation in a flat roof. The upstand is an integral part of the roof light U-value while the joint between roof light and roof forms part of the linear thermal transmittance of the building

Figure 184. An example of a domed roof light installation using back-pan flashing (a ‘saddle’) behind roof lights wider than 1 metre to ensure efficient drainage behind the roof light (to avoid ponding) (see Figure 134). Flashing height of 100 mm is acceptable in this case where the ‘saddle’ produces a fall away from the roof light.

Figure 185. An example of roof light flashing on a warm roof assembly on a supporting profiled steel sheet.

Figure 186. An example of roof light flashing on a warm roof assembly on a supporting concrete deck. The upstand must be insulated to avoid condensate forming. The flashing is carried over and fixed to the outer side of the domed roof light with profile or edge profile to prevent it from sliding down.

6.2 Roof Lights for Pitched Roofs

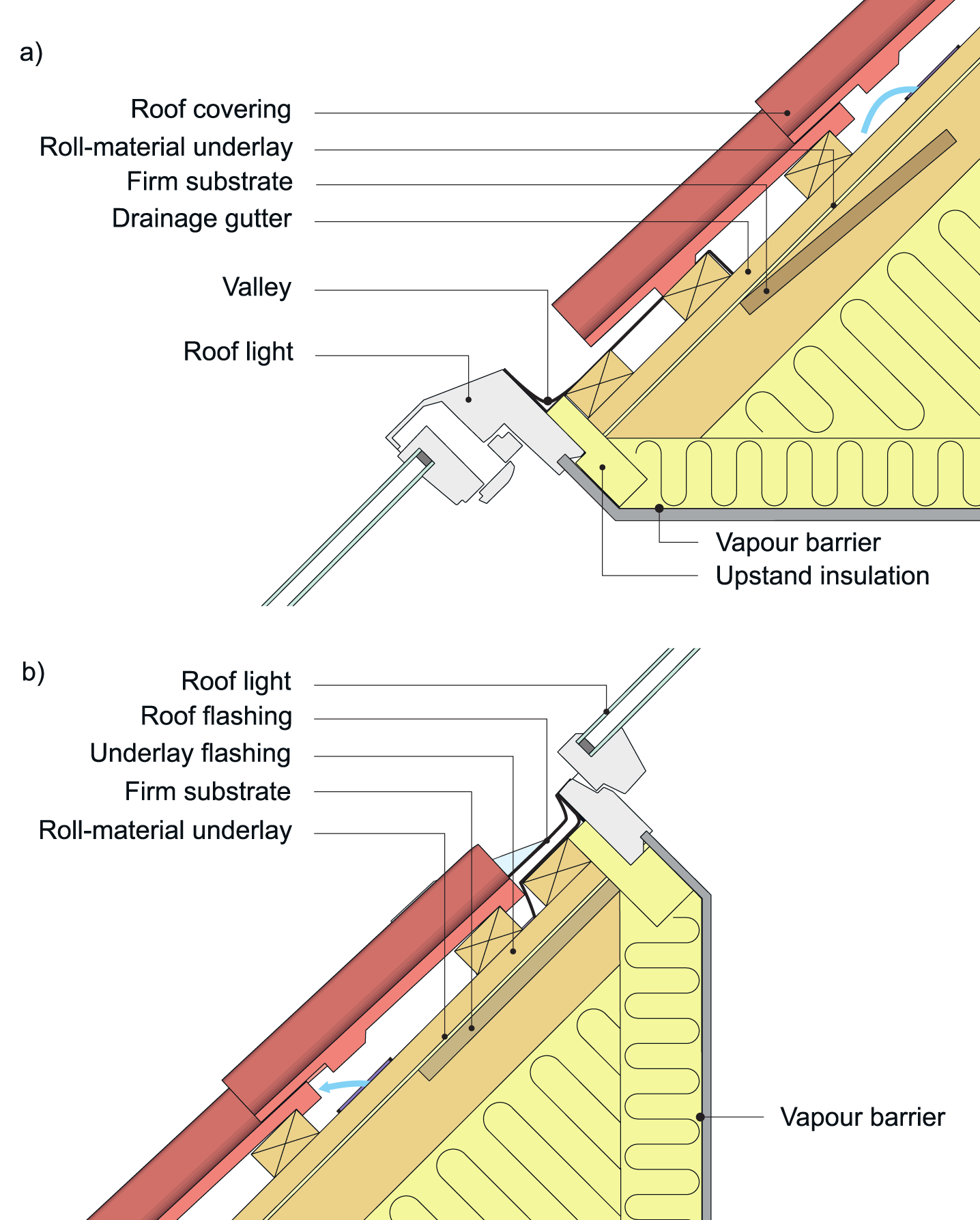

For roof lights in pitched roofs, flashing used both against the roofing underlayment (if applicable) and against the roof covering. The visible part of the flashing is normally made from composite material, zinc, or aluminium. Inside, roof lights must be joined to the vapour barrier or internal cladding with an airtight joint. For this reason, prefabricated flanges are normally used.

Figures 187 and 188 show examples of roof light installation in pitched roofs with roofing underlayment of roll material and firm underlayment, respectively.

Figure 187. An example of a roof light installation in a roof with roll-material underlayment and a covering of roof tiles. Firm decking is installed as the underlayment around roof light to obtain secure adhesion. Joints between roof light and vapour barrier and between roof light and underlayment must be tight (to prevent moisture ingress from the inside and outside, respectively). Ventilation options must typically be fitted (e.g., roof vents in the roofing underlayment) both above and below the roof light. Water on the roofing underlayment from above is diverted round the underlayment by a gully (see Figure 189).

Figure 188. An example of a roof light installation in a roof with firm roofing underlayment and a covering of roof tiles. Joints between roof light and vapour barrier and between roof light and underlayment must be tight (to prevent moisture ingress from the inside and outside, respectively). Ventilation options must typically be fitted (e.g., roof vents in the roofing underlayment) both above and below the roof light. Water on the roofing underlayment from above is diverted round the underlayment by a gully (see Figure 189).

Figure 189. An example of a gully positioned above a roof light installed on firm decking (e.g., plywood).

6.3 Dormers

Dormers are extensions from the roof surface making the accommodation space below the roof more usable by allowing daylight inside.

6.3.1 Types of Dormers

There are several different types of dormers (see examples in Figure 190). Dormers are usually timber-structured, but other materials may also be used. Dormer roof coverings may deviate from the rest of the roof (e.g., dormers in tiled roofs will often have zinc or roofing membrane coverings). The dormer sides (cheeks) can also be structured in several different materials (e.g., zinc or wood). In some cases, dormer cheeks consist chiefly of windows. In the case of zinc dormer cheeks, it is usual practice for cheeks measuring more than 1 m2 to break up the cladding to allow for expansion due to temperature changes.

Today, dormers are usually produced as prefabricated building components. If this is the case, it is important to carefully design the main roof-dormer interface, including dormer flashing, how to execute the interface between dormer and main roof underlayment, how to make airtight joints between dormer and main roof vapour barriers, and how to join the dormer cheek wind barrier with the roofing underlayment in the main roof.

Figure 190. Two dormer designs

6.3.2 Incorporating Dormers

Dormers are complicated and firm decking should therefore be used around them (e.g., timber or plywood) to make the roofing underlayment joint between dormer and primary roof as tight as possible.

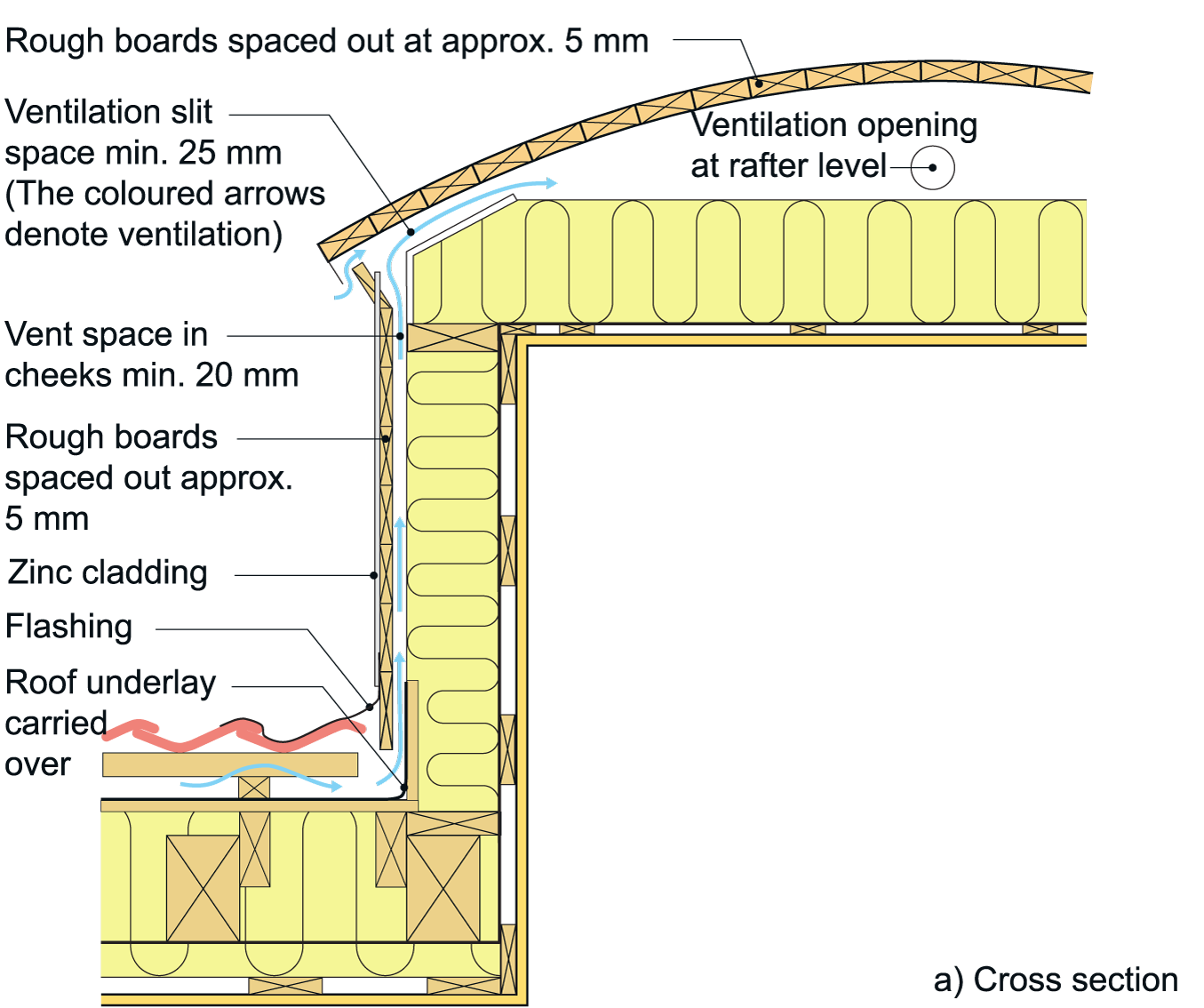

An example of how dormers can be vented and incorporated into the roof is shown in Figure 191. In this example, rainwater is drained from the main roof surface and the dormer via a side gully. The cheeks are vented (via the opening at the bottom) directly between wind barrier and cheek cladding. There must be a min. 20 mm vent space in the cheek between timber of sheet cladding and the insulation or wind-tight layer (e.g., wire-fixed). The dormer roof must have a vented cavity space of min. 45 mm, which must be vented via a min. 30 mm opening. For dormers with a roof surface of less than 2 metres, the height of the cavity space can be reduced to 30 mm if the insulation is fixed (e.g., by wiring or by a vapour-permeable sheet).

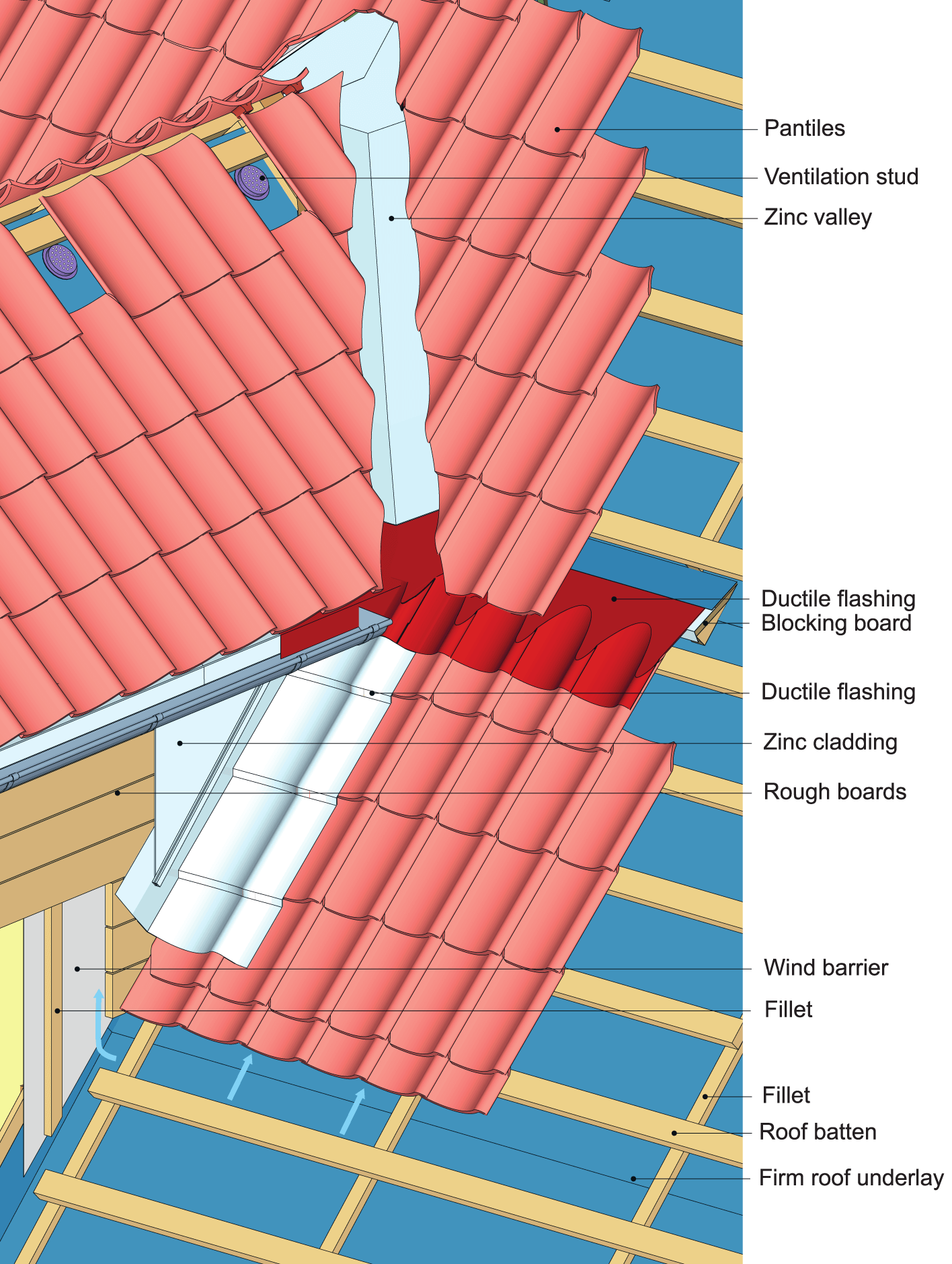

Another option is to carry the cheek flashing over the roof covering. In that case, dormer cheeks are vented from the underside of the roof covering (see Figures 192 and 193).

Further details are available from www.godetage.dk, in Zinkbeklædte kviste (Zinc-Clad Dormers) (Byg-Erfa, 2008b), and in TRÆ 67, Undertage (Roofing Underlayment) (Træinformation, 2013).

When installing dormers, please note that:

- Dormers must be positioned on the roof well away from valleys, hips, and other dormers.

- Water from the dormer itself and water from the above area must be discharged efficiently. Dormer valleys and flashings may have to sustain heavy water loads from the above roof surface.

- Installation of zinc roof coverings must be tight. Small slopes in particular require great care and sealant in the seams. It is recommended that zinc work is carried out by experienced roof and facade installers.

- The intersection with the main roof must be adequately flashed.

- The adhesion between the dormer underlayment and the remaining roof must be tight. Similarly the adhesions between the vapor barrier and these parts must be tight.

- The dormer roof assembly is adequately vented above and below the dormer.

Figure 191. A schematic of the structure of a zinc-clad dormer on a vented roof assembly where roof rainwater is discharged via a side gully. The side gully must be sized according to the water anticipated from the above roof surface. Water from the side gully is discharged into the gutter or onto the roof covering at the bottom of the dormer. Both the dormer cheeks and roof must be adequately vented. The dormer roof ventilation is relative to the shape and slope of the roof. Above and below the dormer, roof vents are inserted in the roofing underlayment (see Section 2.3.2, General Ventilation Guidelines).

The materials outlined in Section 5.6, Zinc and Copper (and Aluminium) are also suitable as underlay for dormer zinc cladding.

Figure 192. A schematic of the ventilation of a tiled roof and dormer with wood board decking for zinc cladding on a dormer cheek. The ventilation path runs from the underside of the roof tiles through the dormer cheeks to the dormer roof. The dormer can be constructed with ventilation from the front to the main roof (see the dotted vent holes and sectional drawing).

Figure 193. A schematic of a roof assembly with dormer where rainwater from the dormer valley is discharged onto the roof surface. The material coloured red at the bottom of the valley indicates ductile flashing placed on the roofing underlayment. The flashing rests on firm decking on both sides which is continued across the roof surface to the right with a ‘blocking-up’ board to ensure that the water from the valley is discharged to the roof tiles. This example valley is finished with flashing of aluminium. Both the dormer cheeks and roof must be adequately vented. The dormer roof ventilation depends on the shape and slope of the roof. In this example it is vented behind the dormer cheek via ventilation below the roof covering. Roof vents are fitted above and below the dormer in the roofing underlayment (see Section 2.3.3, Guidelines for Ventilation of Pitched Roofs) (From www.membran-erfa.dk).