4 COMPOSITE ROOFING SLABS

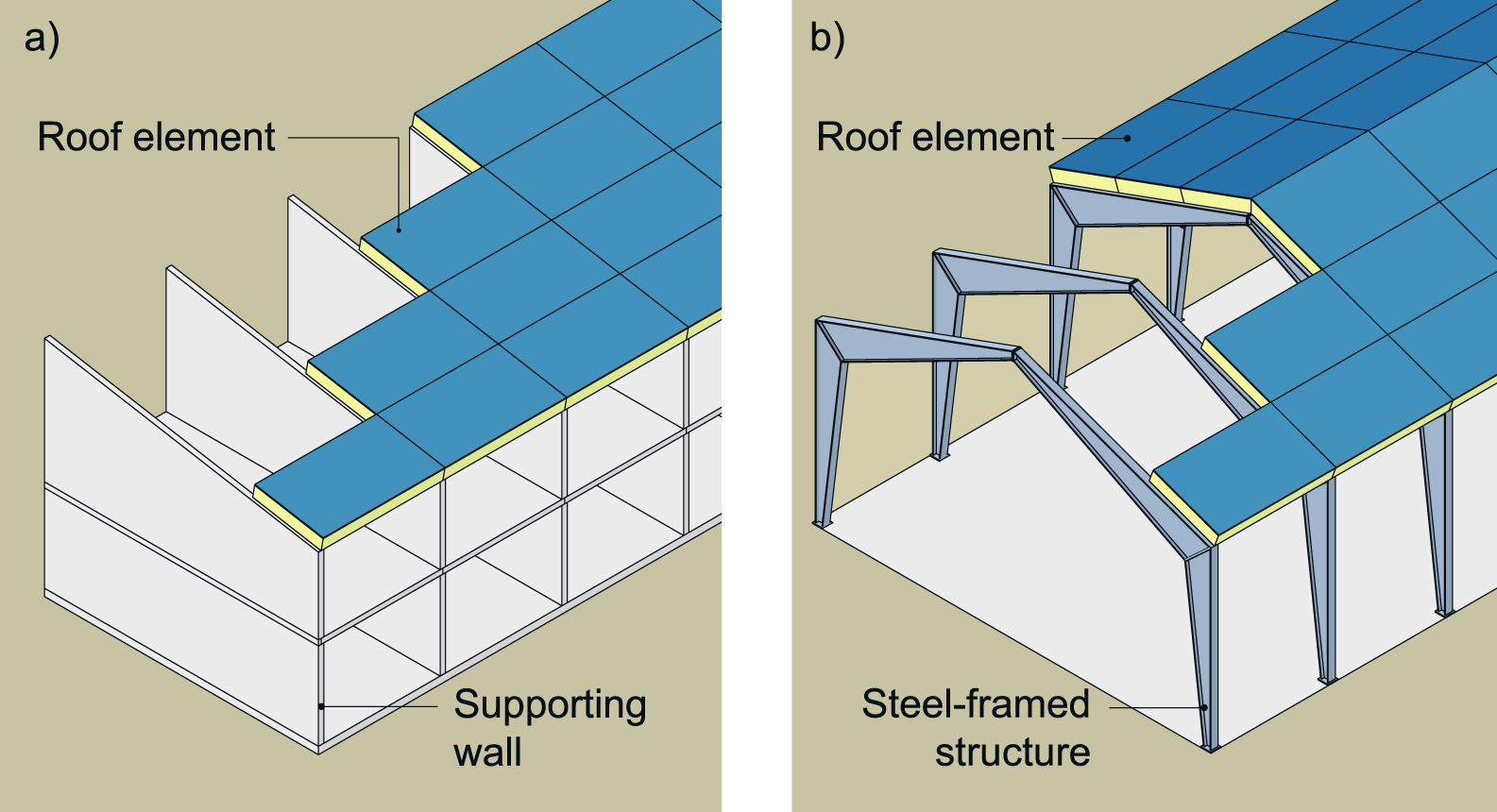

Composite slabs are large, prefabricated units typically containing supporting ribs, thermal insulation, vapour barrier, interior cladding, decking for the roof covering and, in some cases, the actual roof covering itself. The slabs are delivered ready-made to the building site and installed on a supporting substructure (e.g., supporting walls, rafters, or a column-and-beam system) (see Figure 54).

The span of timber-based composite slabs is typically 5–8 metres with ribs made of solid wood. Larger spans can be made when using steel-ribbed slabs or ribs made of glue-laminated wood (gluelam) or laminated veneer lumber (LVL).

When assembling the slabs on site, both vapour barrier and roof covering joints must be tightly fitted. Vapour barrier joints between composite slabs and connecting joints between vapour barrier and adjoining building parts or installations must be tightly fitted to avoid indoor air migrating into the assembly and resultant moisture absorption (cf. Section 2.1.2, Vapour Barriers in Roofs).

Slabs with an integral roofing membrane must be taped over immediately after installation to prevent precipitation from penetrating them. Composite slabs without an integral roofing membrane should be installed under complete cover. Tolerance issues that arise when joining composite slabs are outlined in Section 5.7.4, Constructing a Membrane Roof.

Care must be taken to prevent composite slabs from absorbing moisture during transport, storage, installation, etc. (see e.g., Træbaserede tagelementer – styring af fugtforhold fra fabrik til færdigt byggeri (Wood-based Composite Roofing Slabs –Controlling Moisture from Factory to Finished Building) (Byg Erfa, 2006)).

Composite roofing slabs can also be an integral part of prefabricated offsite housing systems where entire rooms or building units are factory-made and assembled on site. For detailed descriptions of buildings with prefabricated offsite solutions and composite slabs for single-family and terraced housing (see SBi Guidelines 254, Småhuse – styrke og stabilitet (Small Houses – Strength and Stability) (Cornelius, 2015)).

Applicable Standards for Composite Roofing Slabs

The national annex to Eurocode 5: Design of Timber Structures (Danish Energy Agency), 2014, stipulates that until a harmonised standard for wood-based composite slabs has been formulated, prEN 14732-1:2006, Timber structures – Prefabricated wall, floor, and roof elements, published as DS/INF prEN14732-1 (Danish Standards, 2009b) must be used as the basis for certification and control.

In double-skin steel-based composite slabs, DS/EN 14509 (Danish Standards, 2013m) applies.

Figure 54. . Example applications of composite slabs in buildings with various support systems.

- Terraced housing where composite slabs are supported in vertical party walls.

- A warehouse in which composite slabs are supported by a steel-framed structure

4.1 Types of Composite Roofing Slab

Composite roofing slabs can be divided into:

- Vented slabs

- Unvented slabs

Composite roofing slabs can be constructed from timber, metal, or a combination of these.

Examples of common composite roofing slab assemblies and ventilation solutions are shown in Sections 4.1.1–4.1.4.

Further information on design, construction, and installation of light-weight, wood-based composite slabs and how to integrate them into light-weight facade units in multi-storey buildings is available in TRÆ 68, Facadeelementer (Facade Units) Træinformation 2013).

4.1.1 Vented Wood-based Composite Roofing Slabs

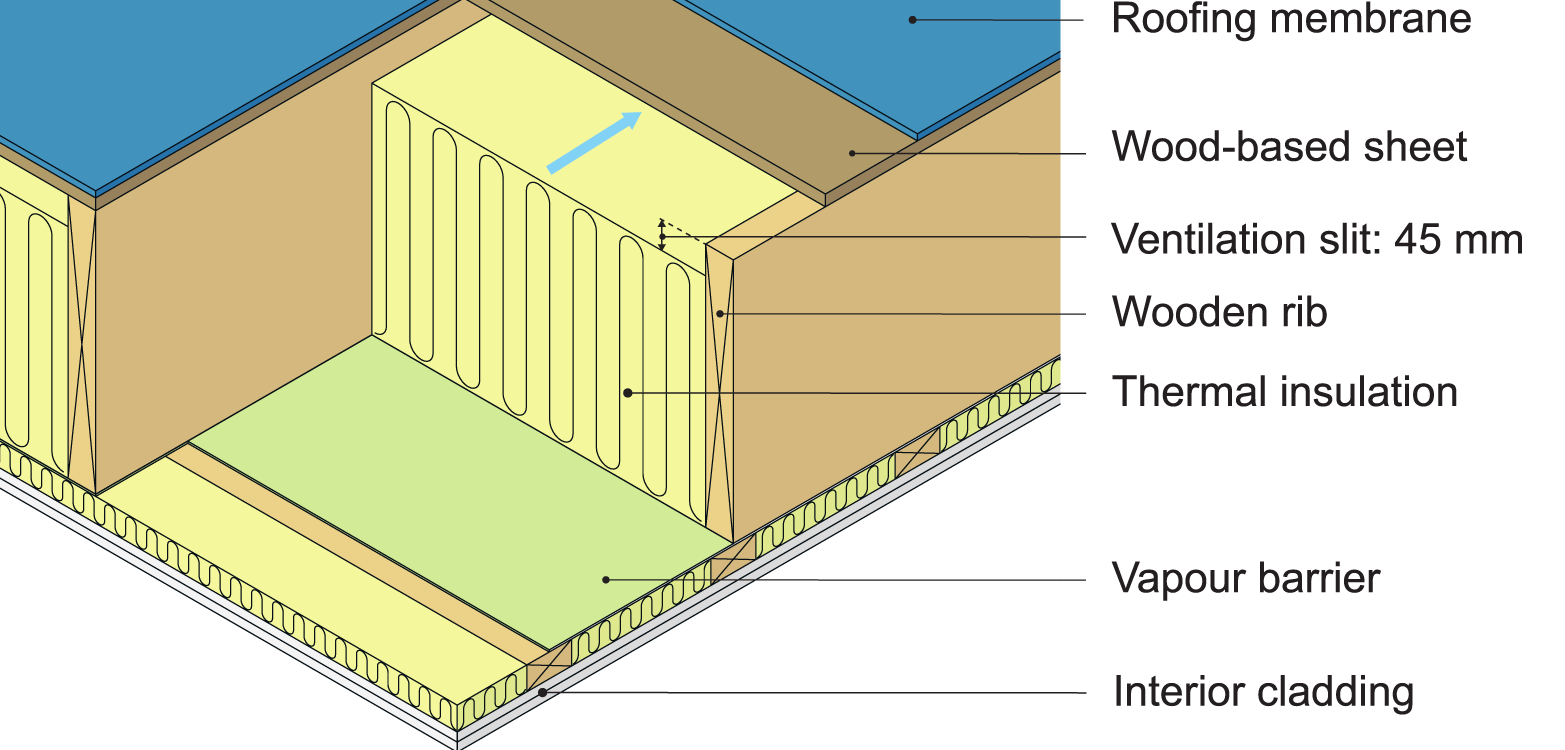

Vented wood-based composite roofing slabs are the most common composite slab type. Their typical construction is shown in Figure 55.

The upper side of wood-based composite slabs is usually a wood-based sheet (typically plywood) which can be nailed (or nailed and bonded) to the wooden ribs. If the slabs are both nailed and bonded, the plywood flange can be included in deformation calculations. Structural gluing of composite slabs requires certification according to system 1 in the Danish annex of Eurocode 5 (Danish Energy Agency, 2014)). If the plywood sheet is nailed to the ribs the effect is reduced and partially coupled cross sections must be considered (cf. Beregning af trækonstruktioner (Calculating Timber Constructions) (Træinformation, 2016)).

Figure 55. Example showing assembly of vented, wood-based, composite slab. Often, 12–15 mm structural plywood is used as underlayment for the roofing membrane. The vapour barrier is placed approx. 45 mm into the thermal insulation (from the inside) for protection. The vented cavity space must be at least 45 mm.

OSB sheets are not generally used for composite slabs, as their moisture-related movement is extensive, resulting in considerable deformation in the composite slabs. Wood boards are not suitable, either, as they cannot provide a shear wall effect.

The moisture content in the plywood on the upper side of the slabs varies during the year due to variations in moisture content of both the outside air (ventilation air) and the indoor air as well as potential leakages in the vapour barrier. During the winter months, moisture content will often reach approx. 18% whereas this level tends to drop to 10–12% during summer. This causes the composite slabs to warp during winter, because the plywood expands, effectively making the outer part bigger than the inner part. This must factored in when designing connecting details to inner walls, which should be fabricated using expansion joints.

4.1.2 Unvented Wood-based Composite Roofing Slabs

Unvented wood-based composite roofing slabs can be used to construct cold roofs with a moisture-adaptive vapour barrier or warm roofs. The basic assembly with wooden ribs and plywood sheets on the upper side corresponds to an assembly of vented wood-based composite slabs (see Section 4.1.1, Vented Wood-Based Composite Roofing Slabs).

Cold Roof with Moisture-Adaptive Vapour Barrier

Unvented wood-based composite roofing slabs can be used to construct a cold roof with a moisture-adaptive vapour barrier. The solution assumes that moisture will dry from the top down through the roof assembly during the summer months. This is possible because solar heating of the roof surface during summer will press moisture downwards towards the vapour barrier. This function, therefore, is conditional on solar heating.

This type of slab is sensitive to shade from other buildings or ventilation housing placed on the roof. Even small areas left in (almost) constant shade (for example by a kerb or firewall parapet on the roof) pose a risk of moisture-induced damage. Their use is therefore limited to large simple roof surfaces without shade (e.g., industrial halls and sports centres where it can be guaranteed that there is no shade on the roof surface and it is likely there won’t be in the future, from the installation of solar panels, for example).

Unvented wood-based composite slabs with moisture-adaptive vapour barriers should, as a rule, be completely filled with thermal insulation material to avoid moisture absorption in their upper regions. Moisture can migrate longitudinally in the slabs, as moisture tends to move in an upward direction. Likewise, moisture may move from sunlit areas to shaded areas, potentially causing moisture absorption in parts of the slab. Generally, the compatibility of solutions with the desired vapour barrier should be assessed, based on moisture calculations.

The roof covering should be dark to absorb solar radiation (e.g., a dark roofing membrane or zinc) so that moisture is driven down to the moisture-adaptive vapour barrier, which will integrate the moisture with the indoor climate where it will finally be vented to the outside. The interior cladding must have a low diffusion resistance (typically with a Z–value below 10 GPa s m2/kg) even after several layers of painting.

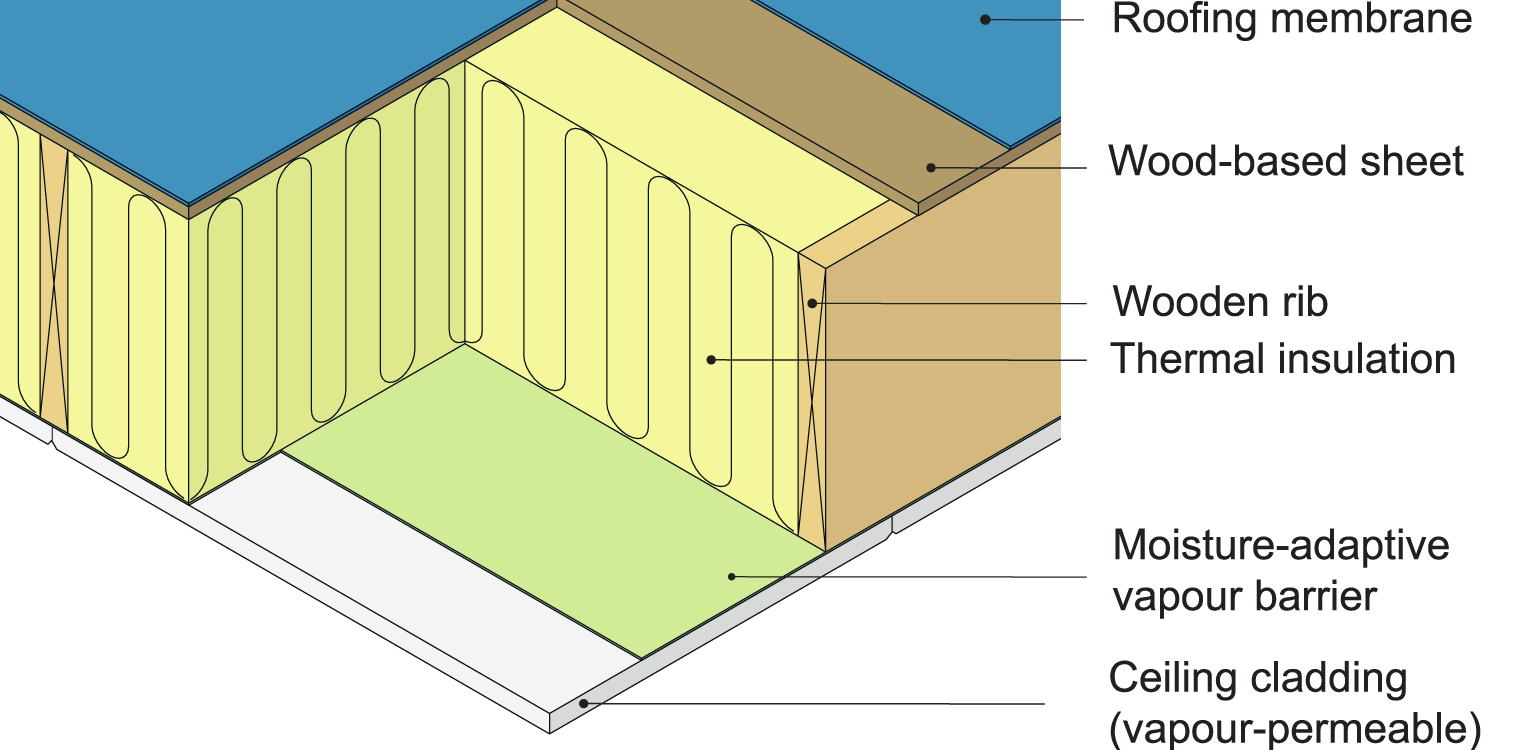

Figure 56 shows an example of a cold unvented composite slab assembly with a moisture-adaptive vapour barrier.

Figure 56. Example of a cold unvented wood-based composite roofing slab assembly whose function is conditional on moisture in the composite slab being driven out via a moisture-adaptive vapour barrier. There will be some minor (harmless) moisture absorption in these roofs during winter, but the moisture is driven out again during summer as a result of the roof being exposed to solar heating. Therefore, it is necessary for the entire roof to be exposed to the sun. The interior cladding must be vapour-permeable, for example, using cement-bonded wood wool sheets as shown in Figure 56, which allows moisture to dissipate during summer.

Warm Wood-based Composite Roofing Slabs

Unvented wood-based composite slabs can be constructed as a warm roof with outside factory-made thermal insulation. The use of composite slabs in a warm roof assembly is a moisture safe solution, that is typically used for moisture load classes 3–5 or when ventilation cannot easily be established. Unvented wood-based composite slabs are sensitive to moisture introduced during construction. It is difficult for moisture to dry out once it has been encapsulated between two tight membranes such as a vapour barrier and a roofing membrane.

To avoid moisture problems in warm roofs where part of the insulation is located under the vapour barrier, the ratio of insulance factors between the insulation above and below the vapour barrier, is subject to specific requirements. This prevents condensation or black mould from appearing in supporting timbers (see Table 5 in Section 1.3.2, Warm Roofs).

Figure 57 shows an example of a warm unvented composite slab assembly.

Figure 57. Example of unvented wood-based composite slab assembly designed as a warm roof for use in moisture load classes 1–2 (see Section 1.3.2, Warm Roofs for guidelines on the thermal insulation thickness ratios above and below the vapour barrier). Geotextile fabric is only relevant if porous ceiling sheets such as cement-bonded wood wool sheets are used (shown here).

Unvented Steel-based Composite Roofing Slabs

The advantage of unvented steel-based composite roofing slabs constructed with supporting steel ribs and profiled steel sheets is that they are impervious to decay and dry rot, unlike wood-based composite slabs. On the other hand, moisture in composite slabs can lead to corrosion.

Steel-based composite slabs can be sensitive to moisture during the building process. It is difficult for moisture to dry out once it has been encapsulated between two tight membranes such as a vapour barrier and a roofing membrane.

Steel-based composite slabs are supplied with a factory-made roof covering and only require the joints between the slabs to be sealed immediately after installation. In theory, drying-out is only possible via pressure compensation towards eaves, and therefore a moisture-adaptive vapour barrier should be used. Alternatively, special attention must be given to keeping the composite roofing slabs dry throughout the process, for example, by packaging effectively during transport and storage and by keeping the building site under total cover.

The ribs in steel-based composite roofing slabs are prone to thermal bridging which must be factored into heat loss calculations and assessments of condensation risk.

Composite slabs can be supplied with large-scale spans (lengths), which is often considered desirable, as it reduces the necessary construction.

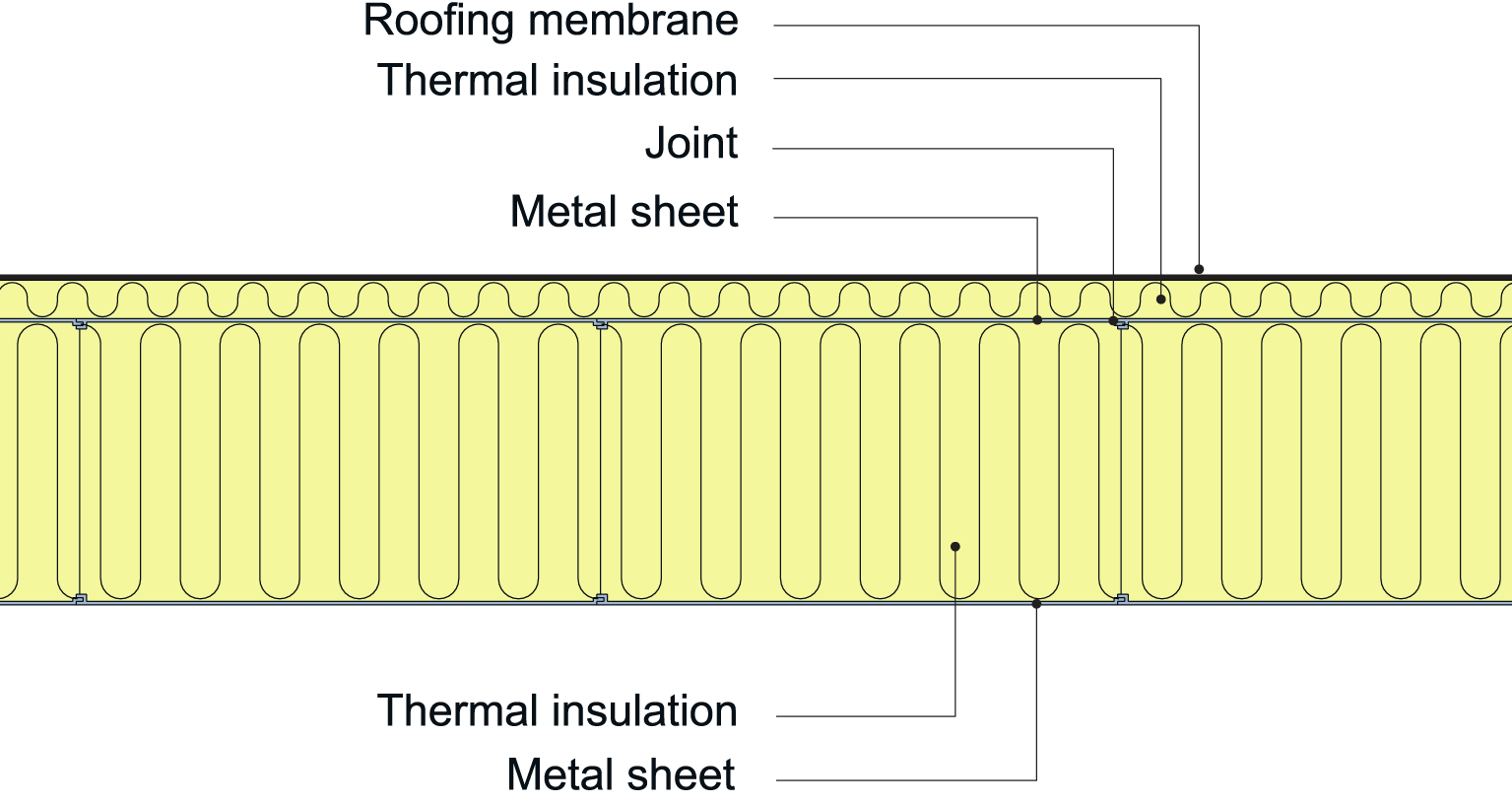

Figure 58 shows an example of an unvented steel-based composite roofing slab assembly.

Figure 58. An example of an unvented composite roofing slab assembly with supporting steel ribs and profiled steel sheets. Precautionary measures must be taken to avoid thermal bridging (e.g., by enhancing external insulation).

Figure 58 continued. An example of an unvented composite slab assembly with supporting steel ribs and profiled steel sheets. Special attention must be given to avoiding thermal bridging.

4.1.3 Unvented Steel-based and Wood-based Composite Roofing Slab

Composite slabs can also be structured from parts consisting of both steel and wood. The steel is used for long spans and the wood as decking for the roof covering.

This type of composite slab is sensitive to moisture from the building process and must be delivered with a factory-made roof covering. Leakages can be fatal for this type of composite slab as the structural properties are compromised if the interconnection between steel and wood fails.

In cases where the roof covering consists of roofing foil, small amounts of moisture may, in theory, dissipate through the roof covering. However, this will take a long time and is usually ineffective in practice.

The use of this type of composite slab in Denmark is very limited.

4.1.4 Double-Skin System

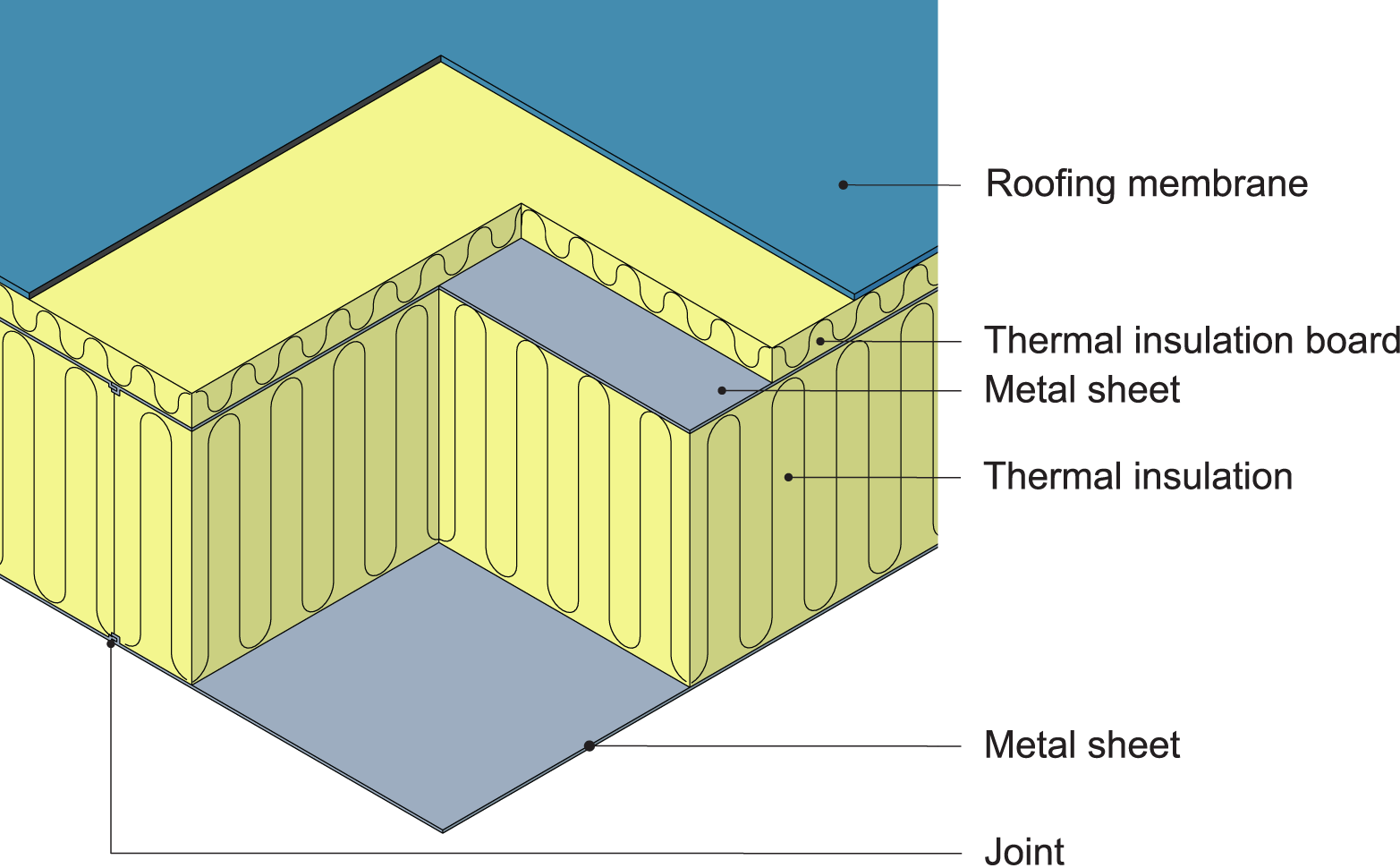

In cold stores, composite slabs are often structured as double-skin slabs with steel or aluminium flanges filled with a core of rigid-foam thermal insulation such as mineral wool or PUR foam (see Figure 59).

The advantage of this type of composite slab is that it is completely enclosed by a vapour-impermeable metal sheet at the top and bottom of the slab, preventing any moisture from entering the assembly from either side of the slab.

Special fire performance rules apply to double-skin composite slabs with a core of flammable thermal insulation such as PUR foam. This type of composite slab can only be used once a fire performance assessment has been performed for each usage case.

Figure 59. Example of steel-based composite slab designed with a double-skin system and a totally vapour-impermeable layer of metal sheets on either side of the thermal insulation. Steps must be taken to avoid thermal bridging (for example increasing the outside insulation).

4.2 Details – Composite Roofing Slabs

This section shows typical examples detailing in assemblies using wood-based composite roofing slabs. For further information, please see manufacturer installation instructions and literature.

When designing roofing details, normal guidelines must be followed for several specific issues, including guidelines on ventilation and provisions in the Building Regulations for fire performance and thermal insulation. General issues concerning the choice of roof are outlined in Section 1.1, Roof Design.

Further examples of detail design are provided in Section 9, List of Examples.

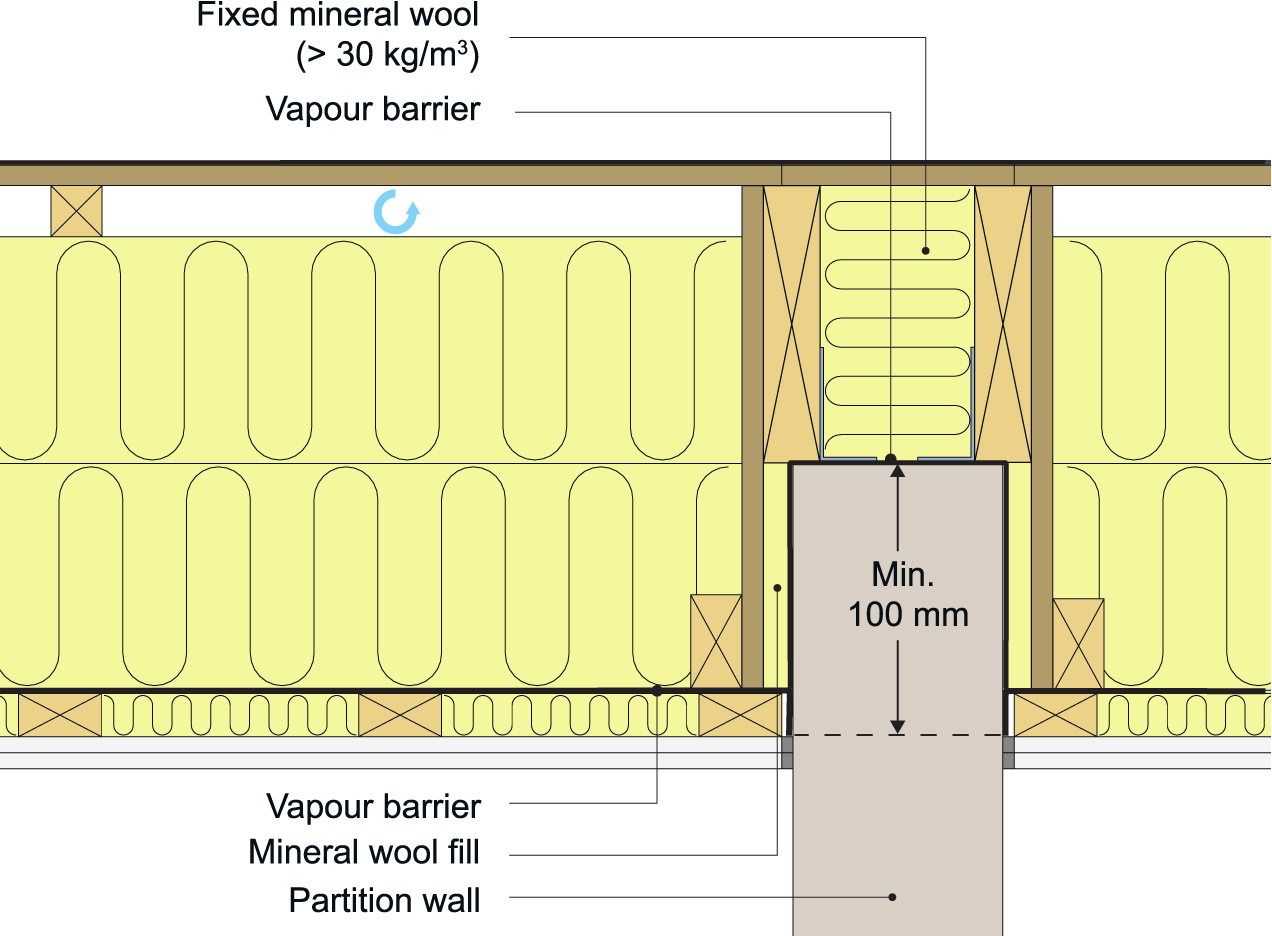

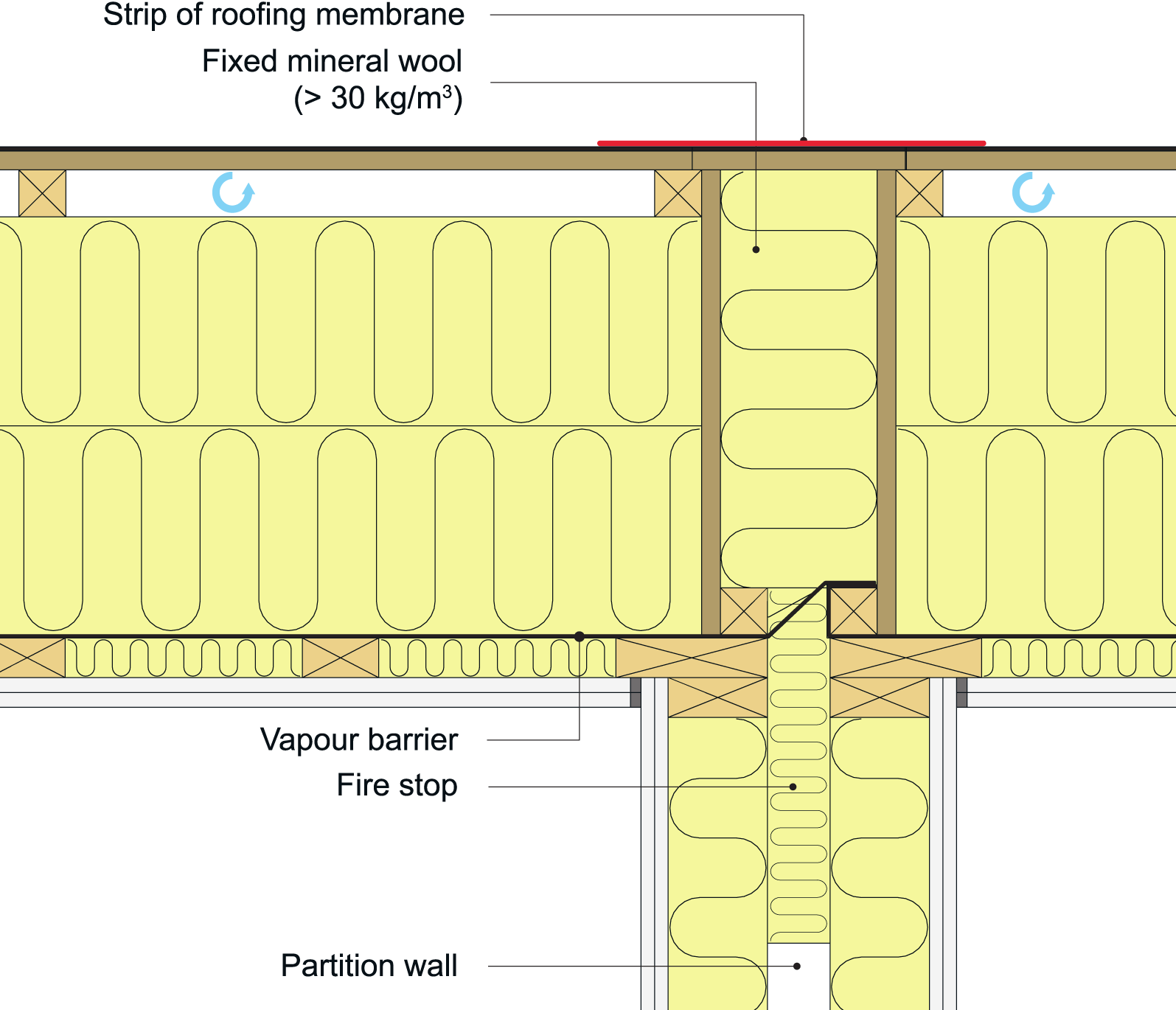

Junctions with Party Walls

When joining composite slabs across party walls (fire-sectioning), it is necessary to observe existing provisions for the prevention of flame spread, acoustic insulation, and minimising linear thermal transmittance (thermal bridging).

To prevent flame spread and minimise thermal bridging, the wall can be extended with mineral wool to the underside of the roof covering (density > 30 kg/m3).

If party walls have new moist concrete walls, the composite slabs must be protected from moisture absorption when installed (e.g., with a vapour barrier placed across the concrete wall).

Requirements regulating fire safety, acoustic insulation, and energy are detailed in Section 1.1, Roof Design.

Figures 60 and 61 are examples of how to join composite slabs across party walls

Figure 60. Example of firewall parapet replacement at junction of vented wood-based composite slabs over concrete party wall. To safeguard against flame spread and minimise thermal bridging, the wall is continued up to the underside of the roof covering with mineral wool (density > 30 kg/m3).

If new moist concrete walls are used, the composite slabs must be protected against moisture absorption when installed (e.g., as shown with a vapour barrier placed across the concrete wall). Concrete walls are generally constructed with generous tolerances; there are typically 15 mm seams on either side of joins and they are repacked with mineral wool on site. The vapour barrier from the composite slab and the one placed over the concrete are pressed together against the concrete wall using a batten with a fitted strip of expanded foam.

If new moist concrete walls are used, the composite slabs must be protected against moisture absorption when installed (e.g., as shown with a vapour barrier placed across the concrete wall). Concrete walls are generally constructed with generous tolerances; there are typically 15 mm seams on either side of joins and they are repacked with mineral wool on site. The vapour barrier from the composite slab and the one placed over the concrete are pressed together against the concrete wall using a batten with a fitted strip of expanded foam.

Figure 61. Example of a fire parapet replacement, constructed by joining vented wood-based composite slabs across a party wall (a wall made of double wooden composite slabs). To prevent flame spread and minimise thermal bridging, the wall can be continued to the underside of the roof covering with fixed mineral wool (density > 30 kg/m3). This roof assembly is class EI 60 on both sides of the party wall but can also be constructed as class REI 60 with a width of 1 metre on just one side of the party wall.

Joining Composite Roofing Slabs

To avoid moisture absorption in composite slab junctions, it is important to ensure that the roof covering and vapour barrier are tightly fitted (see Figures 62 and 63).

Figure 62. Examples of vented composite slab junctions.

- Junction with ventilation transverse to tensioning direction. Width of connecting piece should be at least 30 mm.

- Junction with ventilation longitudinal to tensioning direction.

Figure 63. Example of transverse joint between unvented composite slabs

Eaves with Overhang

When constructing eaves with overhangs and using plywood decking as a roofing membrane, the underside of the plywood may become very cold relative to the surrounding elements (due to radiation emission to the atmosphere) and hence may become wet with a risk of black mould. If feasible, the risk of black mould can be reduced by installing 25 mm of non-flammable thermal insulation on top of the plywood. This raises the temperature on the underside of the plywood. Alternatively, the risk of black mould can be reduced by using plywood with an anti-mould impregnated surface.

Examples of roofing membrane eave enclosures with overhangs and gutters are shown in Section 7.3.5, Flashing the Eaves.