7 FLASHINGS – PENETRATIONS AND INTERSECTIONS

7.1 General Considerations

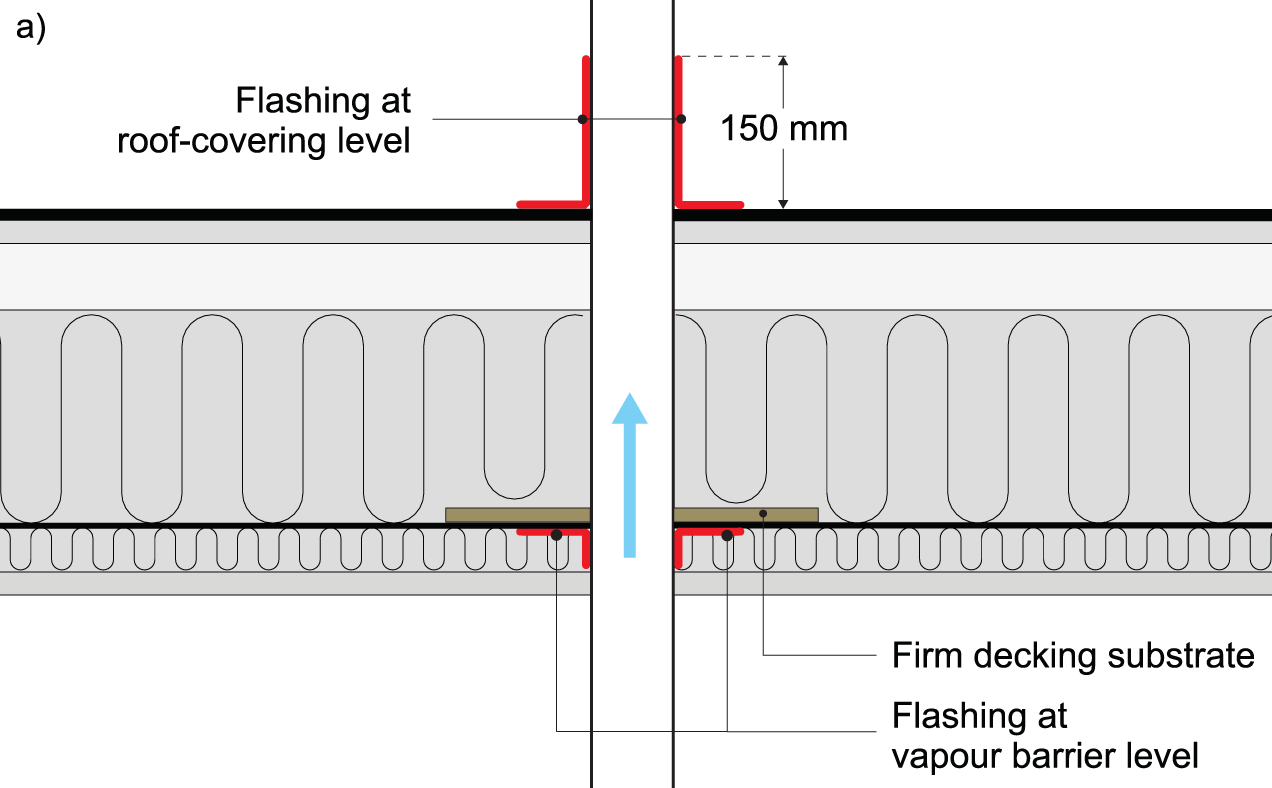

Where there are penetrations and intersections, it is necessary to flash sufficiently high to prevent water from being pressed into the assembly. Flashing height should normally be min. 150 mm. For roof slopes above 15 °, a flashing height of 100 mm will normally be sufficient.

Intersections with, and penetrations of, external walls, ventilation ducts, chimneys, and soil stacks for example, must be installed tightly at all levels of the roof assembly. This includes:

- At the primary roof level

- At the roofing underlayment level

- At the vapour-barrier level.

Furthermore, penetrations and flashings must be executed to resist anticipated mechanical impact and to give them a long lifespan. Penetrations must therefore be fixed and be bonded as a rule. Alternatively, taped joints must be executed on a firm underlay, ensuring correct adhesion. For example, penetrations in vapour barriers or roofing underlayment are installed on a firm underlay which the vapour barrier or underlayment can be fixed and bonded to. At roofing-underlayment level, sealing is also possible by using a fixed flange which could be secured to the roof battens. A firm underlay can be made of sheeting (e.g., 18 mm plywood). The underlay must be sufficiently large to ensure a safe and durable joint.

Penetrations in the roof surface must be positioned with sufficient clearance around them to allow each penetration to be correctly flashed. There should be a min. distance of 500 mm between penetrations, and between penetrations and intersections. Flashing must not be placed in valleys and should be no closer than 500 mm to valleys.

For penetrations where condensate may occur (e.g., in pipes) anti-condensation insulation must be fitted.

In the next section, separate treatment is given to flashings in discontinuous roof coverings (e.g., roof tiles and slate) and continuous roof coverings (e.g., roofing membranes).

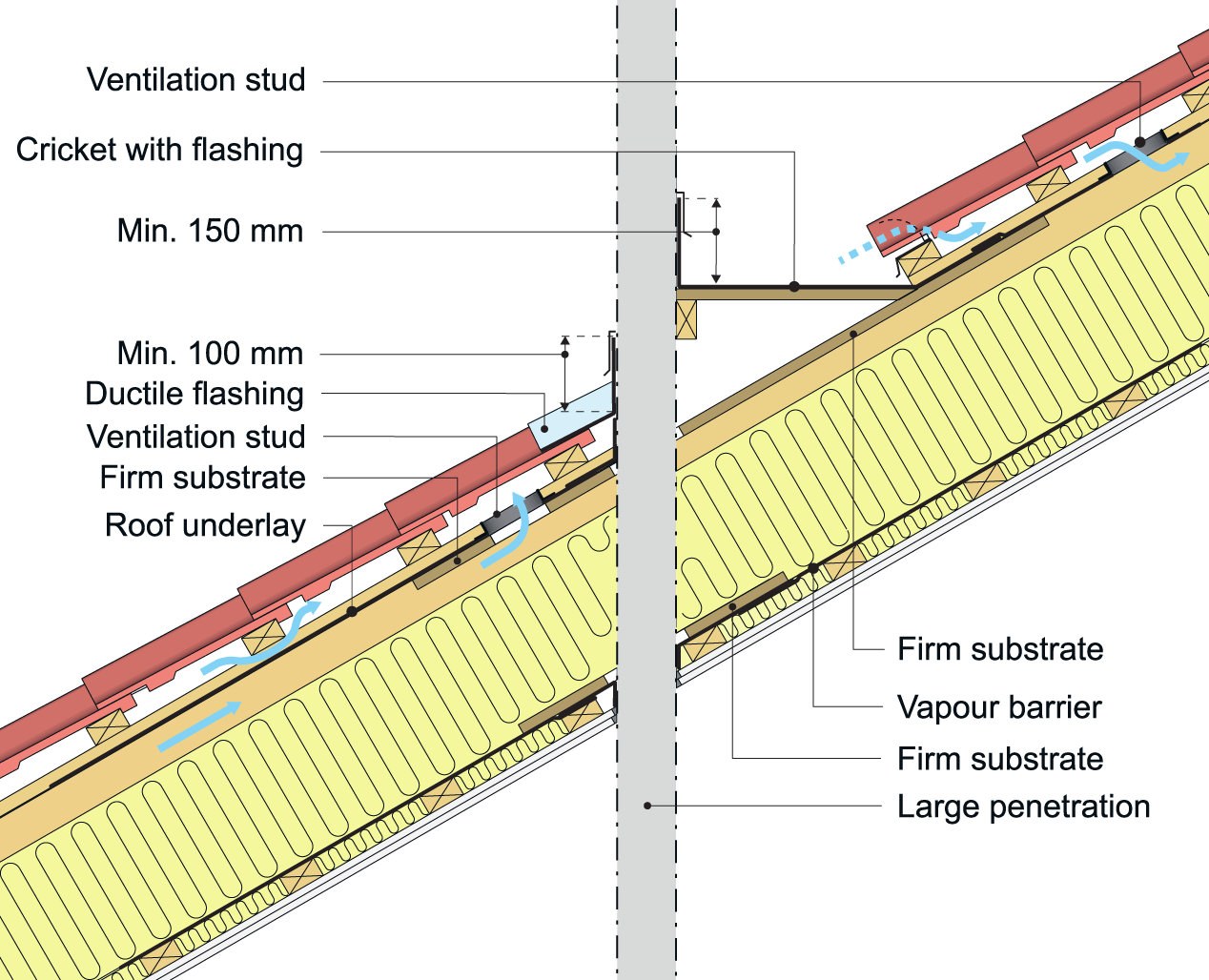

For large penetrations, it may be necessary to establish a so-called cricket (’saddle’) above the intersection. The cricket ensures that rainwater bypasses the intersection.

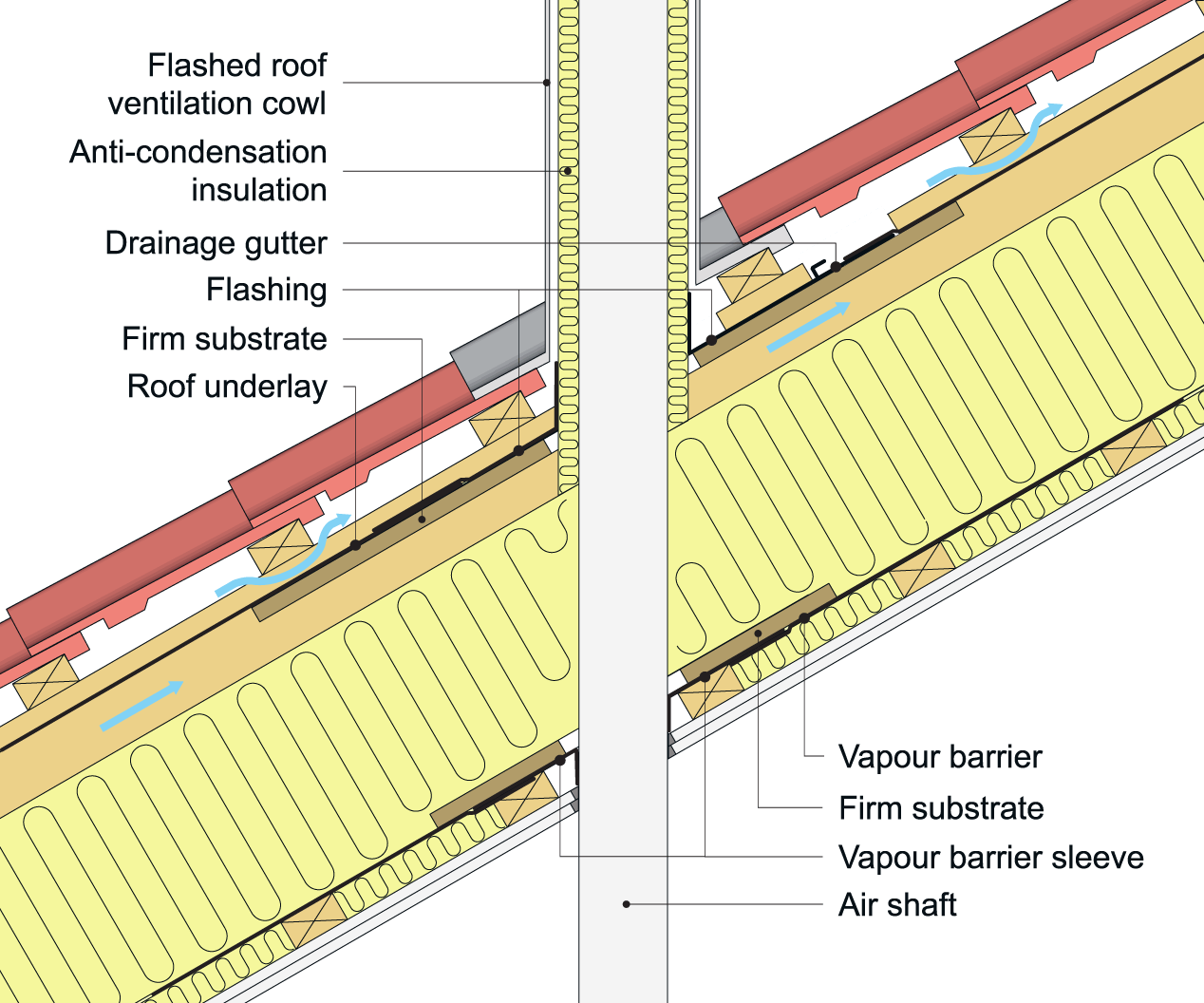

For small penetrations (e.g., air shafts), prefabricated roof vent cowls will ensure tightness relative to the roof covering. The tightness relative to the vapour barrier and underlayment can be achieved by using prefabricated sleeves above the firm underlay securing adhesion at the vapour-barrier and underlayment levels. To divert water from the roofing underlayment round the intersection, a gully can be fitted on a firm underlay above the intersection. Air shafts must be fitted with anti-condensation insulation right down to the insulation layer.

Issues concerning flashing around dormers, roof lights, and skylights are outlined in Section 6, Dormers, Roof Lights, and Skylights.

7.2 Roofs with Discontinuous Roof Covering

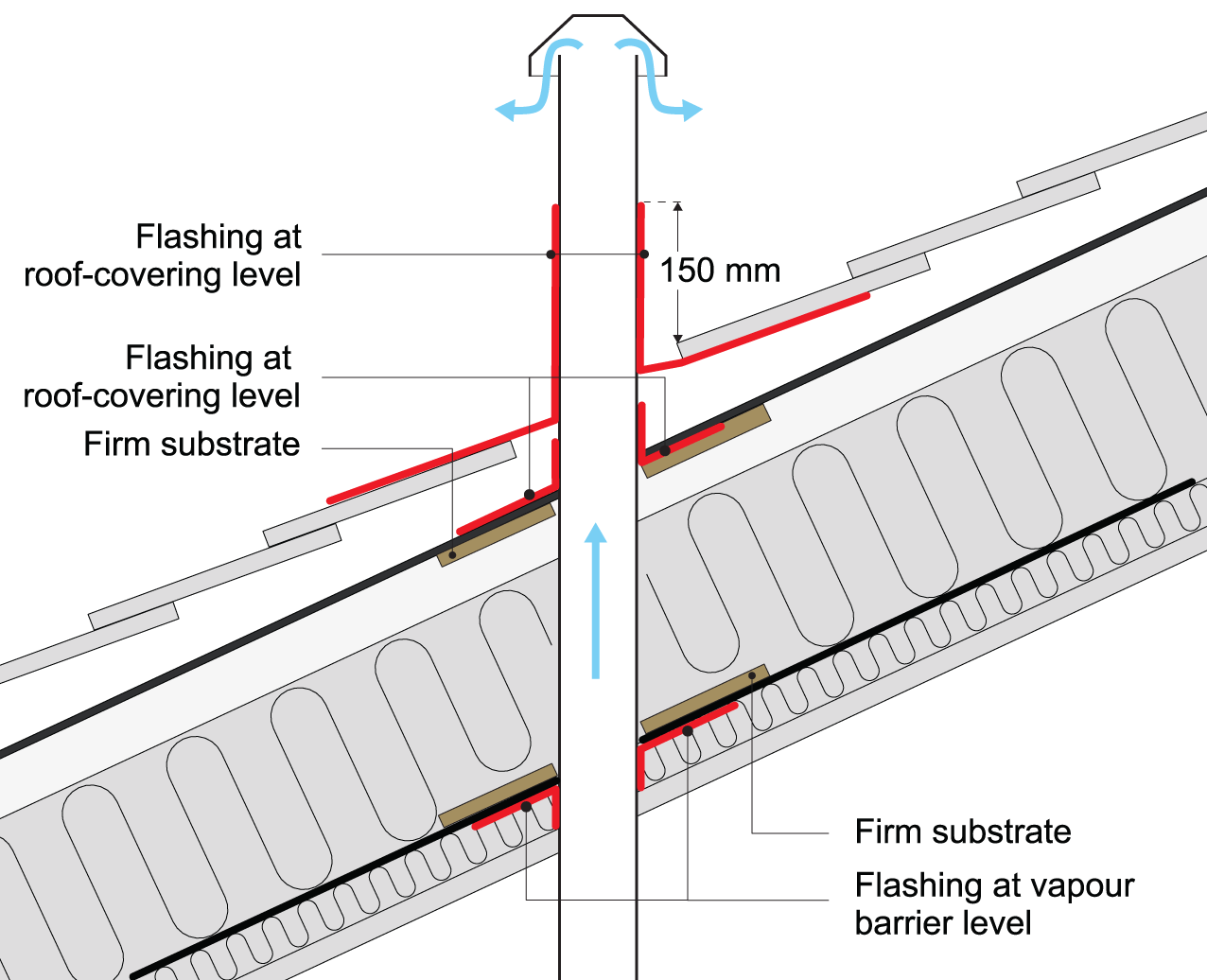

Penetrations (e.g., for ventilation ducts or soil stacks), in roofs with a discontinuous roof covering must be flashed at the roof-covering level, the roofing-underlayment level (if underlayment is used), and at the vapour-barrier level. According to usual practice, flashings at roof-covering level must be watertight up to 150 mm above the roof covering, see Figure 194. For slopes above 15 °, chimney flashing height may sometimes be reduced to 100 mm.

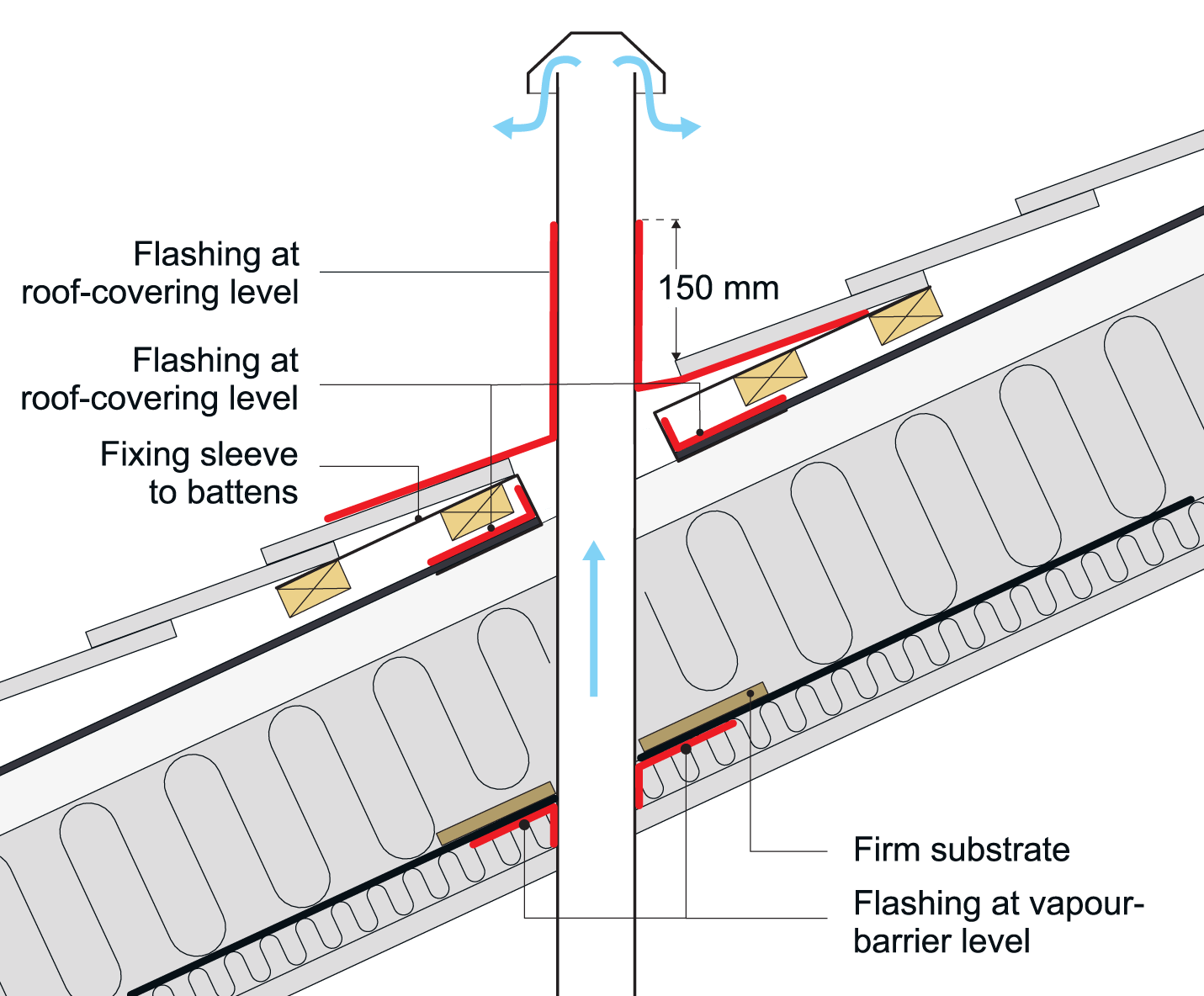

Roofing underlayment flashings will ensure that water from the underlayment does not penetrate the building. Normally, underlayment is fitted tightly around penetrations. It is also generally acceptable for penetrations at the underlayment level to be executed with a special sleeve that does not fit tightly round the penetrations. This means that the sleeve is slightly bigger than the pipe passing through it, but this ensures that water is diverted around the intersection or sleeve (see Figure 195).

At roof-covering level, flashing is fitted with pebbles or sheets intended for penetrations on the specific roof covering, or with ductile flashing, which can be adapted to the roof covering.

When retrofitting penetrations in existing roofs, solutions other than firm decks may be necessary. Nevertheless, attention must be given to fixing the penetration and the roofing underlayment and to diverting any water on the underlayment safely around the intersection.

For metal roofs and certain roofing foils, bonded solutions exist for use in renovations (e.g., where a new penetration is established in an existing roof). Such renovation solutions must be executed according to manufacturer instructions and the usability of the solution should be documented.

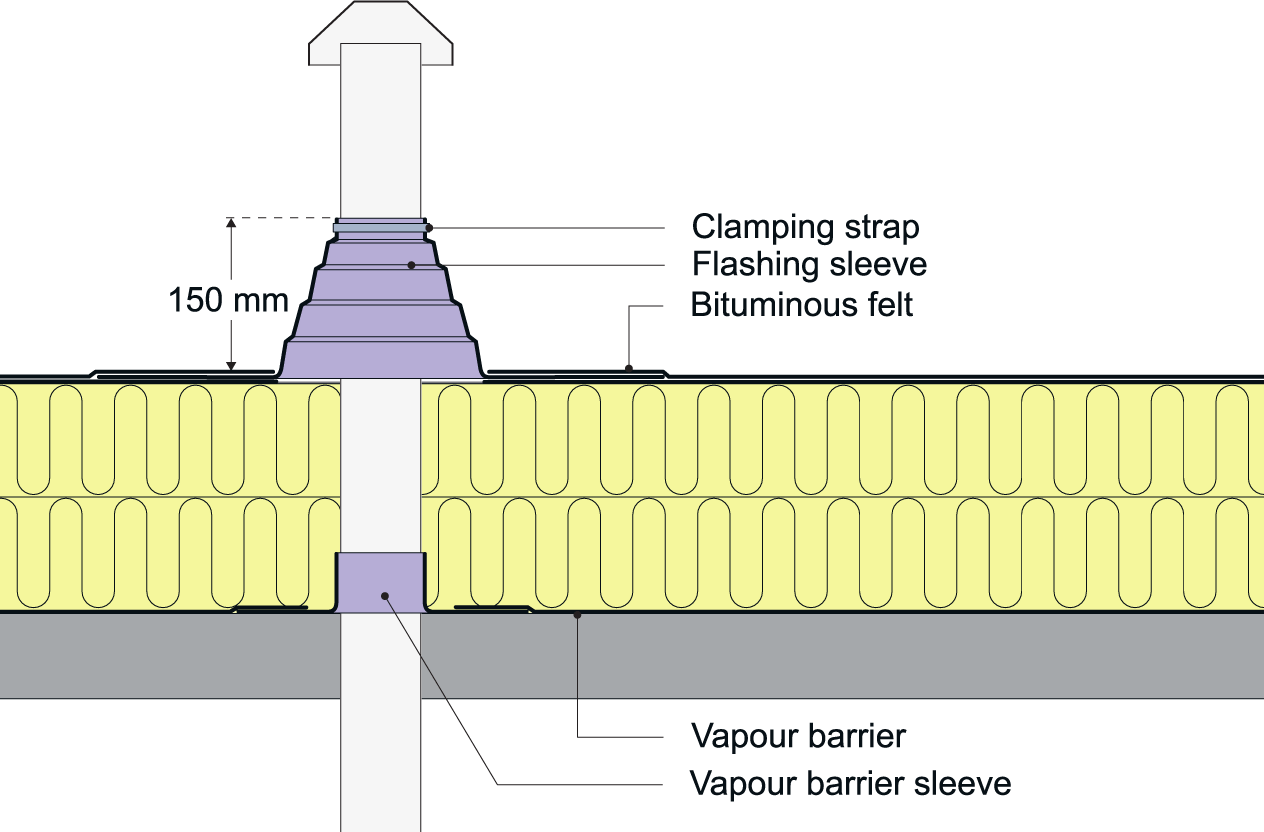

Figure 194. A schematic of penetration flashing in a discontinuous roof covering. Flashing must be done at the vapour-barrier, the roofing-underlayment (if used), and the roof-covering levels. A firm underlay must be established for both vapour barrier and underlayment (alternatively, the fixing and tightness of the penetration must be secured in other ways). For slopes above 15 °, the flashing height for air shafts may be reduced to 100 mm.

Figure 195. A schematic of penetration flashing in an existing roof with roofing underlayment. The penetration of the underlayment is executed with a pre-mounted membrane sleeve. The membrane is fixed to the roofing underlayment by bonding (after cleaning it thoroughly). The sleeve is fixed to adjacent battens with fixtures.

7.2.1 Flashing at Vapour-Barrier and Underlayment Level

In discontinuous roof coverings, the vapour barrier must be installed so that it is airtight at all intersections (e.g., ventilation ducts and soil stacks) (see examples in Figure 196).

Figure 196. Examples of penetrations on a firm underlay of 15 mm plywood.

- Square flanged ventilation duct fixed to firm underlay. In this example, the vapour barrier is fixed to the flange using tape.

- Round ventilation duct with flexible pipe sleeve fixed to vapour barrier on firm underlay using tape.

- Prefabricated sleeve with cable. The sleeve is bonded directly to the vapour barrier on the firm underlay.

General guidelines for the use of vapour barriers in roofs are outlined in Section 2.1.2, Vapour Barriers in Roofs.

The roofing underlayment must be flashed for watertightness around penetrations to prevent water ingress.

7.2.2 Flashing Penetrations

This section shows examples of flashing at roof-covering, roofing-underlayment, and vapour-barrier levels for large and small penetrations in tiled roofs (see Figures 197 and 198).

Figure 197. An example of flashing and ventilation around a large penetration in a tiled roof with a vented underlayment (e.g., a chimney or roof light). A firm underlay is established for the intersection with the underlayment, and roof vents are placed above and below the intersection, and are potentially supplemented by vent tiles. By establishing a back-pan flashing above the intersection, the water is diverted round the intersection. The height of the flashing must be adequate, relative to the roof slope (see above).

Figure 198. An example of the flashing around a small penetration in a tiled roof with vented roofing underlayment. To seal small penetrations (such as air shafts) prefabricated roof vent cowls can be used at roof level, and prefabricated sleeves can be used on a firm underlay for joining the vapour barrier and roofing underlayment. Water from further up the roof can be diverted around the intersection by a gully installed on a firm underlay.

7.2.3 Flashing Adjoining Building Parts

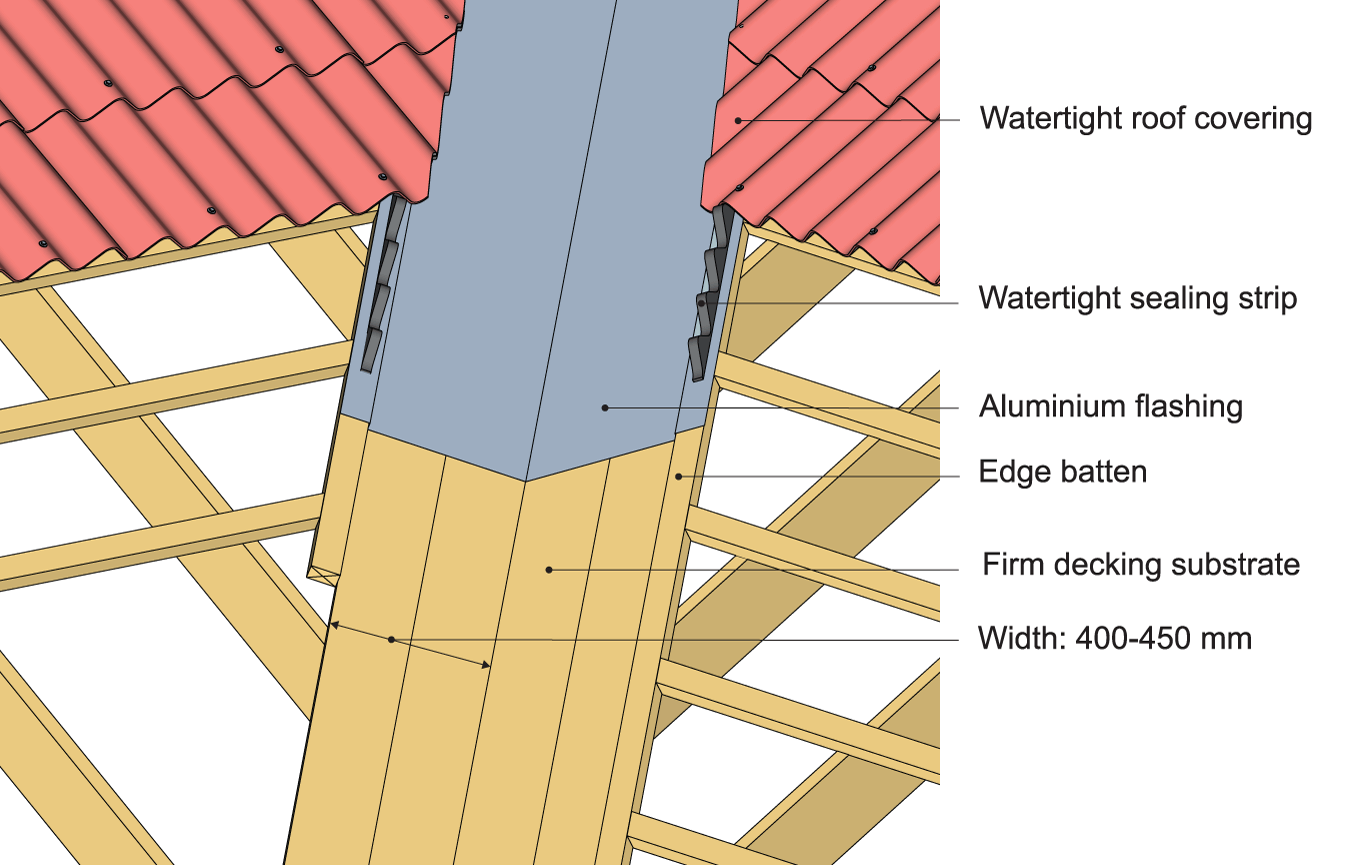

Flashing adjoining building parts is done at roof-covering level, underlayment level, and vapour-barrier level.

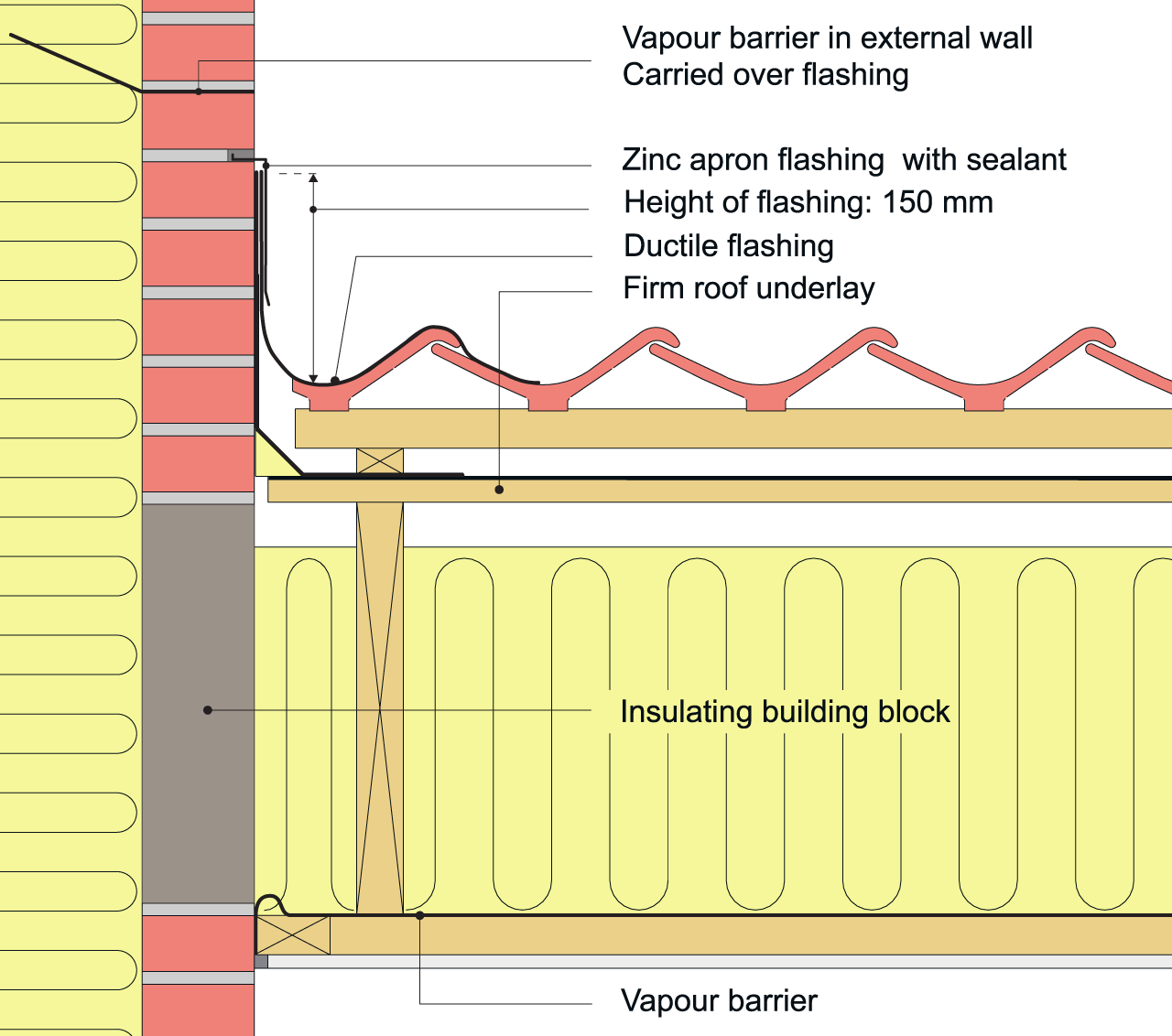

Flashing height must normally be min. 150 mm. For slopes above 15 °, flashing height for chimneys may, for example, be reduced to 100 mm.

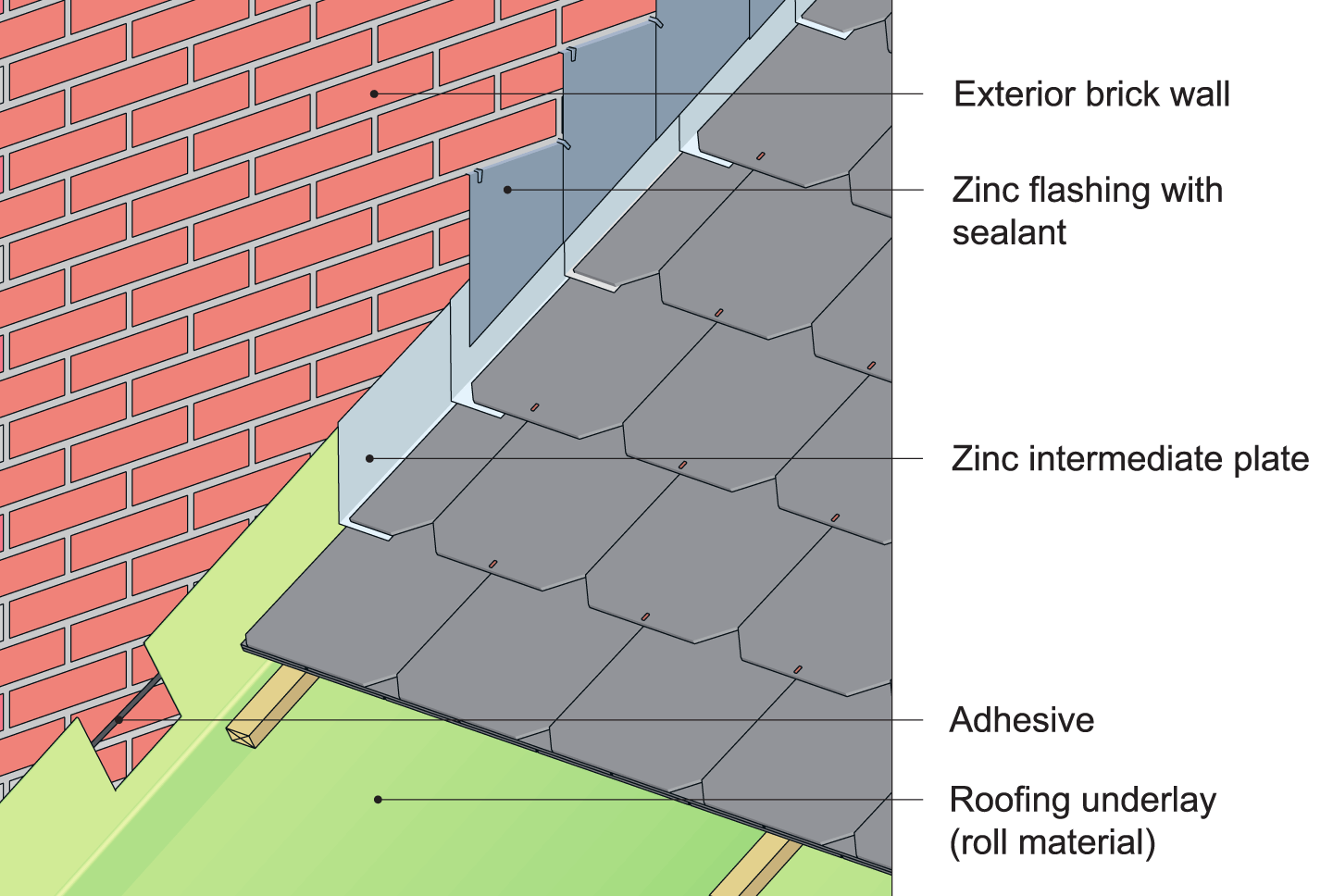

Brick wall flashing is always finished with a reglet. Flashing between a sloping roof surface and exposed brick (e.g., chimneys) is achieved using step flashing (see Figures 200 and 201).

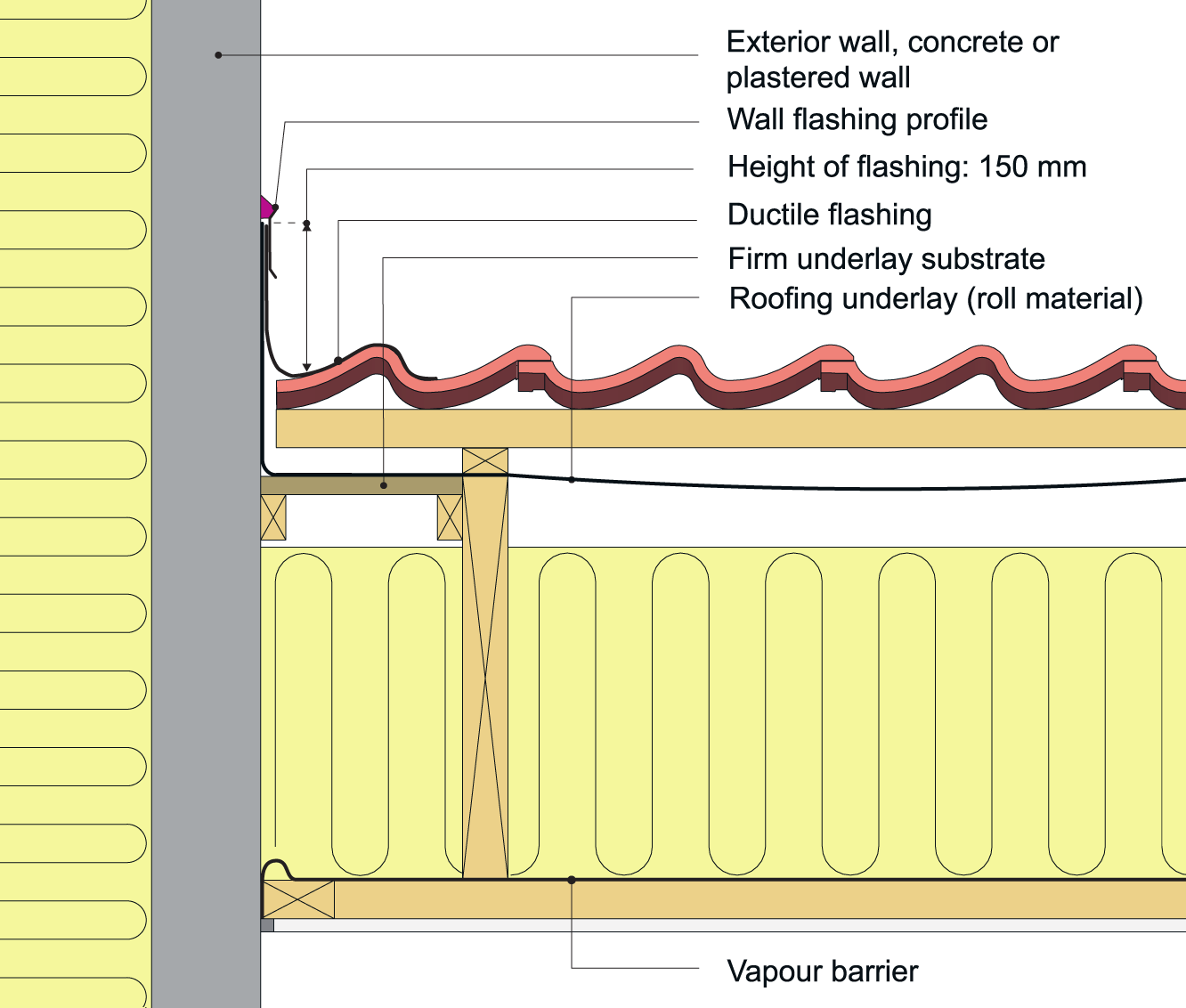

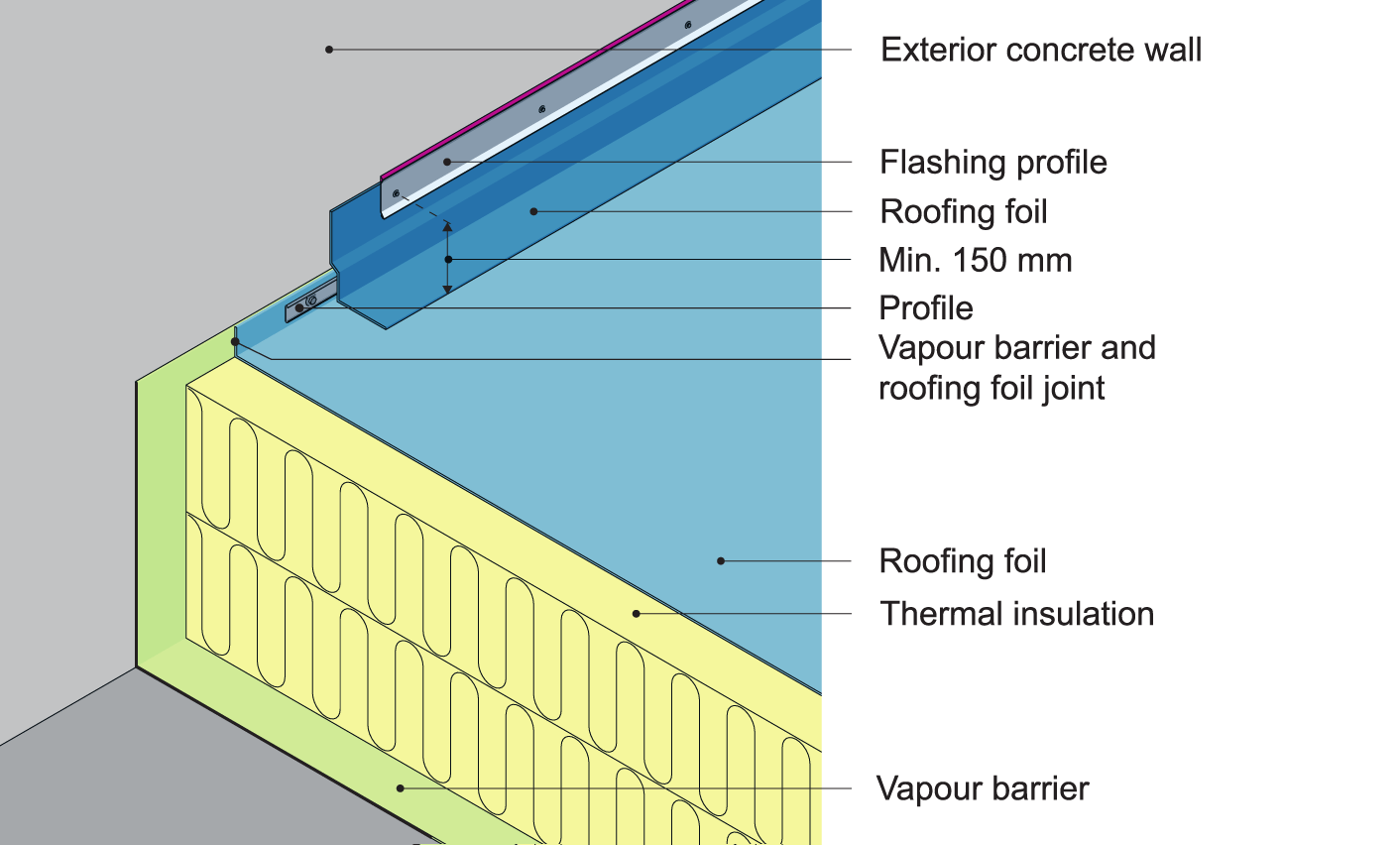

Concrete wall flashings are fixed using flashing termination bars or clamping strips, which are finished at the top with sealant (see Figure 202).

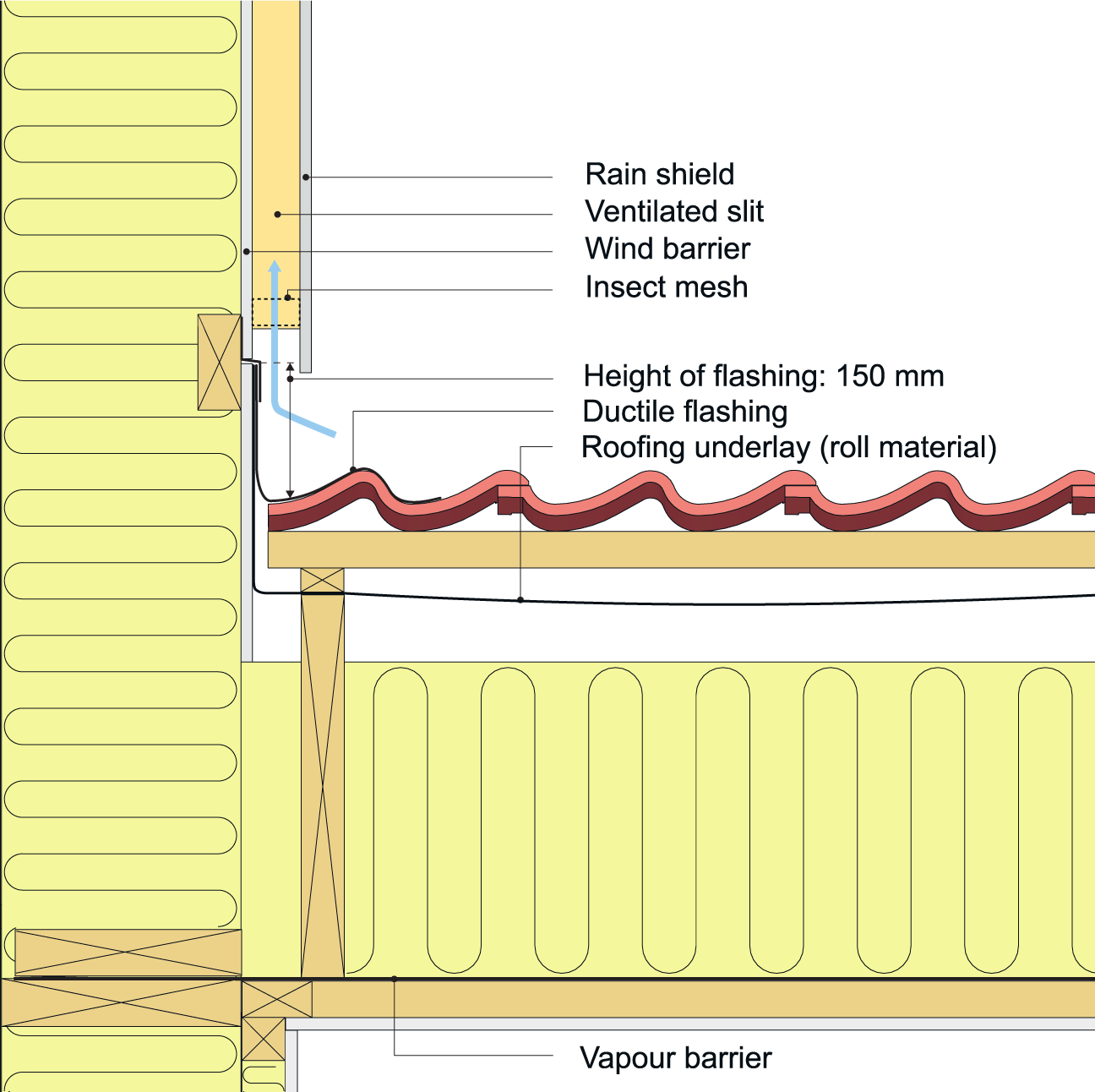

Light facades are flashed by continuing the flashing under the wind barrier (see Figure 203).

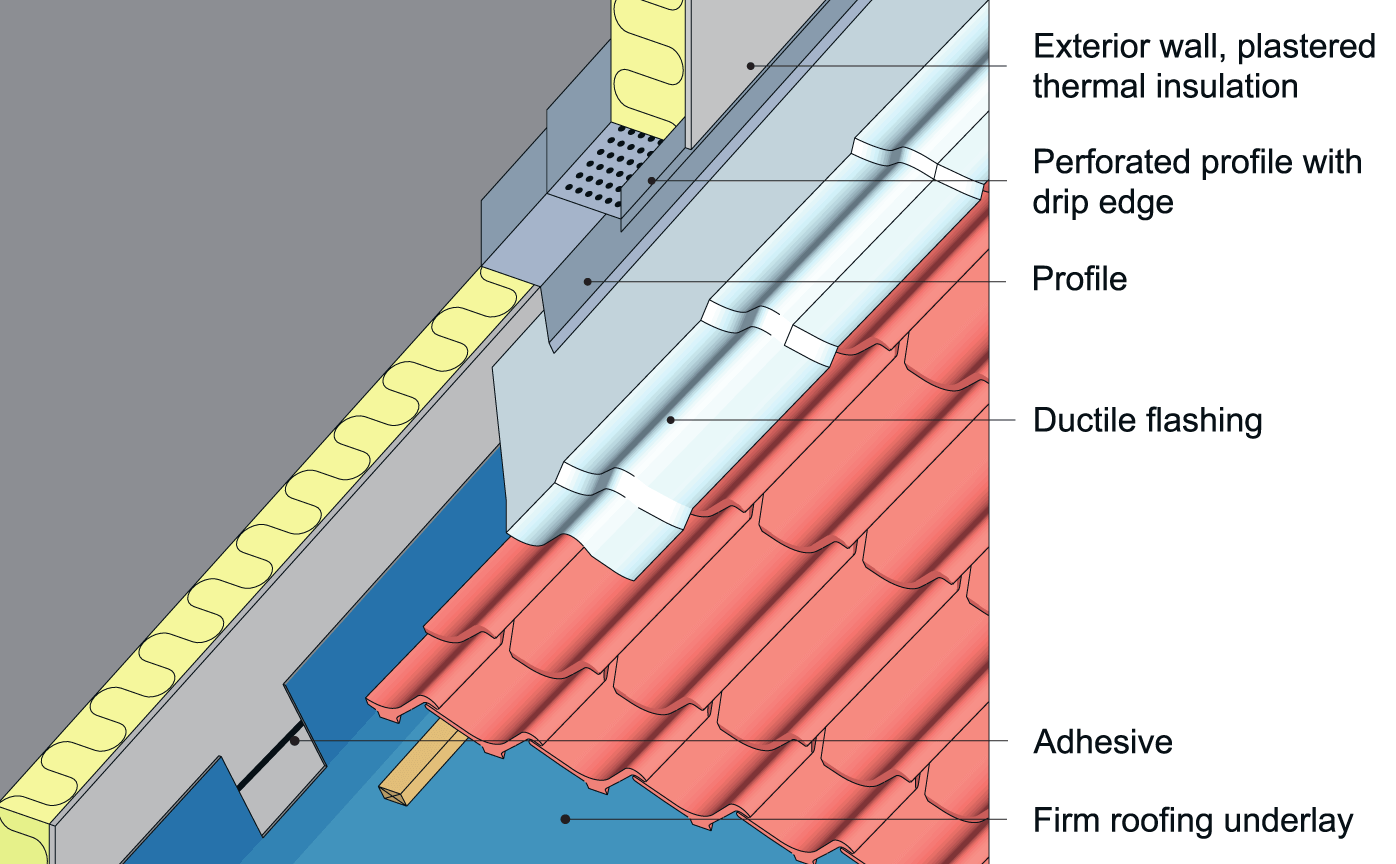

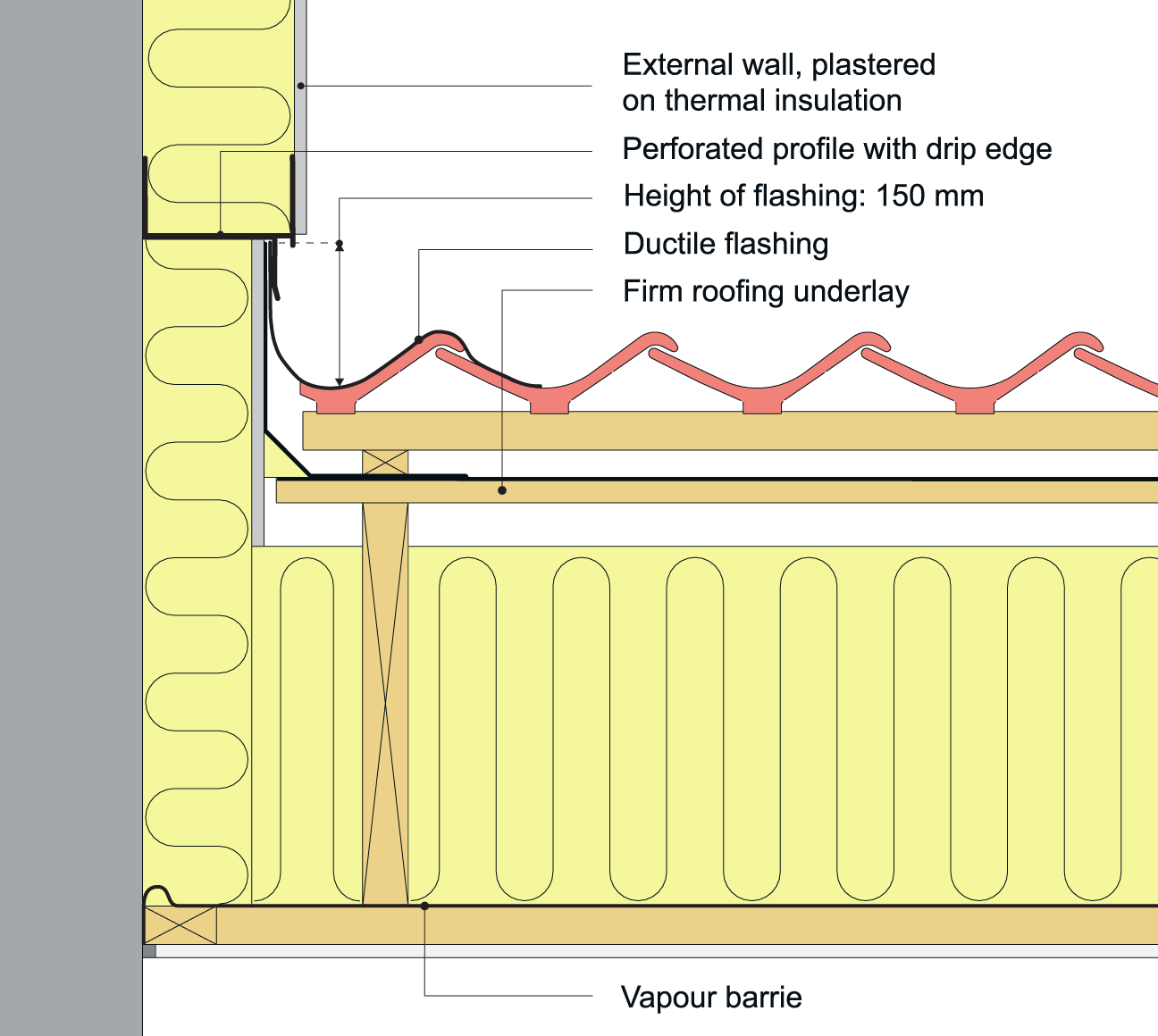

Flashing external plastered thermal insulation is installed against a sheet mounted below the insulation. Tightness should be maintained into the thermal insulation underlay (see Figure 204).

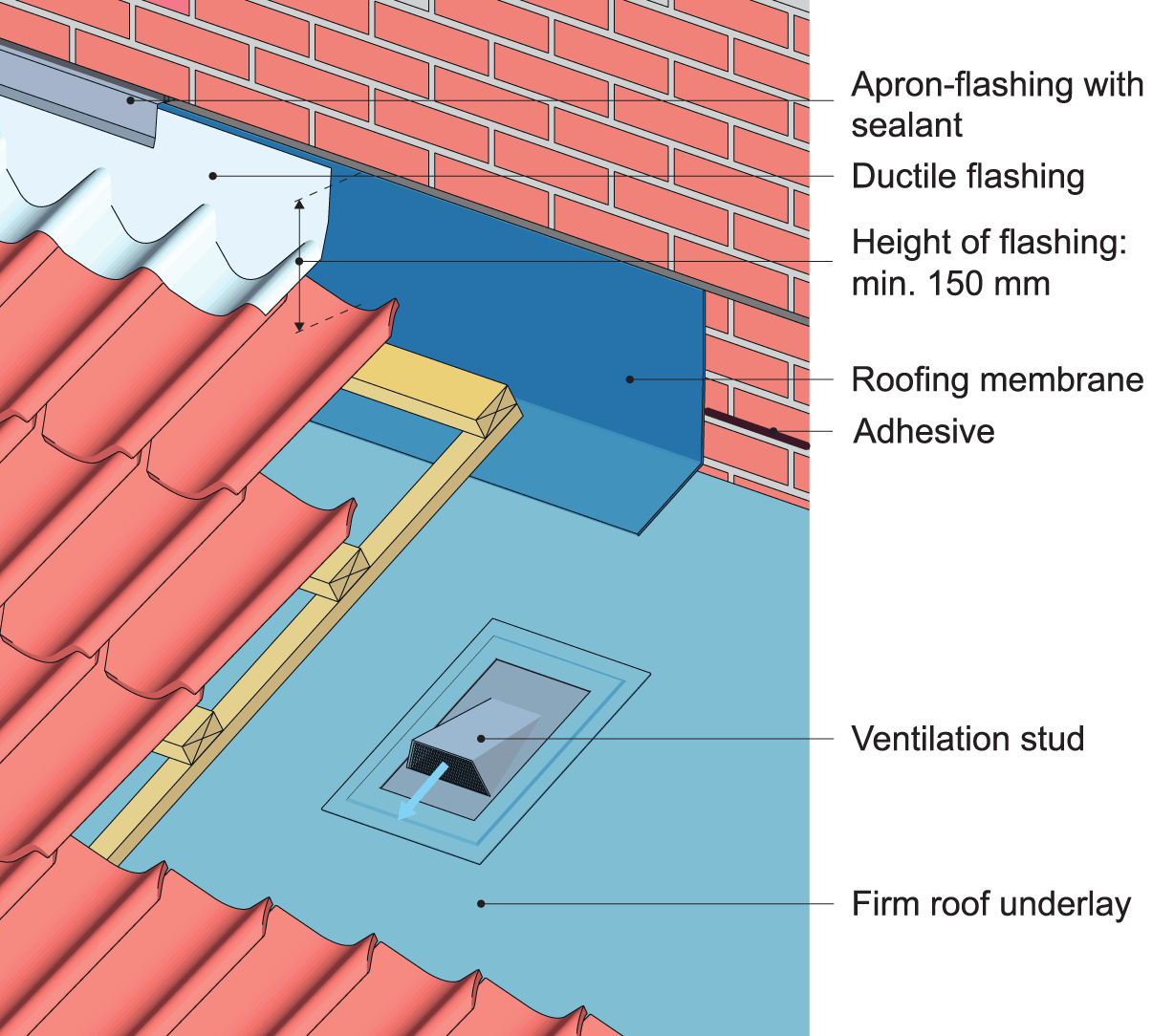

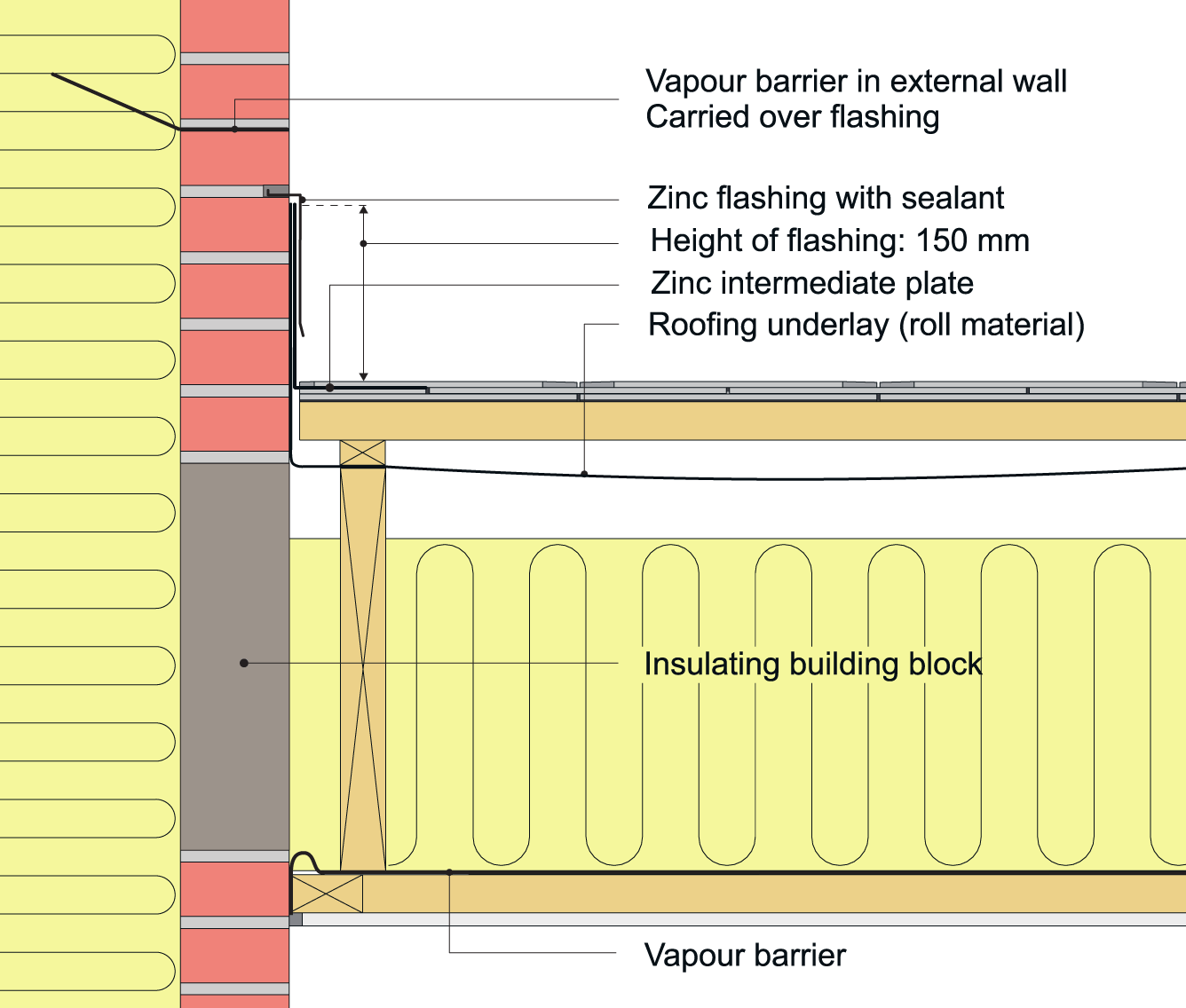

Figure 199. An example of flashing at a horizontal intersection of external brick wall and clay-tile roof on a firm roofing underlayment. For slopes above 15 ° receding from the building being flashed, the height of the flashing may be reduced to 100 mm.

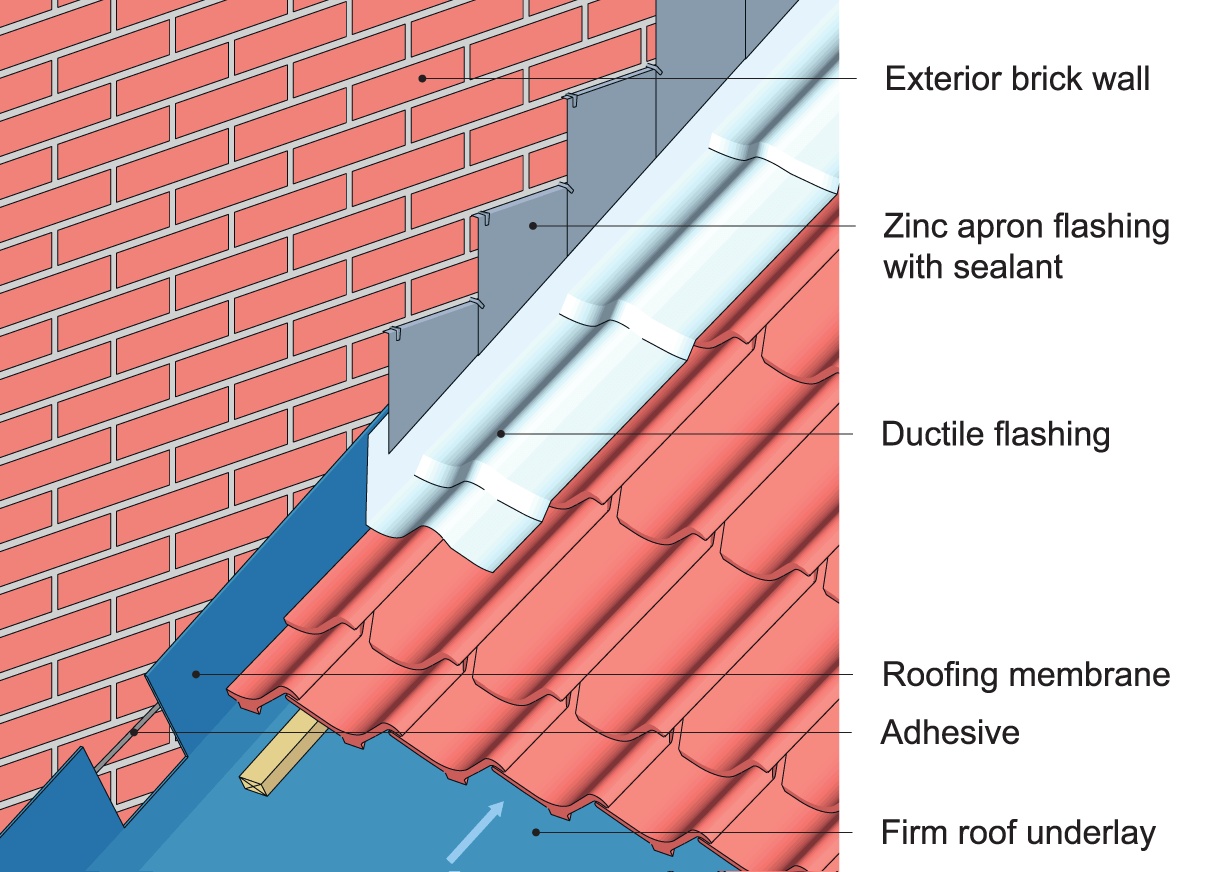

Figure 200. An example of wall-to-roof flashing with exterior brick wall and clay-tile roof on firm roofing underlayment. There are tight intersections at the vapour barrier, roofing underlayment, and roof covering levels. A similar solution is applicable on the sides of brick chimneys.

Figure 201. An example of wall-to-roof flashing on an exterior brick wall and slate roof with roll-material underlayment. A similar solution is applicable on the sides of brick chimneys.

Figure 202. An example of wall-to-roof flashing of a concrete wall and concrete-tile roof on roll-material underlayment. Where there are large spaces between exterior walls and rafters, firm decking should be used for the roll-material roofing underlayment.

Figure 203. An example of the flashing of a light external wall with vented rain shield and a concrete-tile roof on roll-material roofing underlayment. A similar solution is applicable to dormers.

Figure 204. An example of flashing for an exterior wall with plastered thermal insulation and pantile roof on firm roofing underlayment.

7.2.4 Valleys

Valley assemblies typically fall into the following two types:

- Concealed valleys where the bottom of the valley is countersunk into the rafters and the upper side of the valley is flush with the top of the rafters.

- Raised valleys where the valley is installed on top of the rafters.

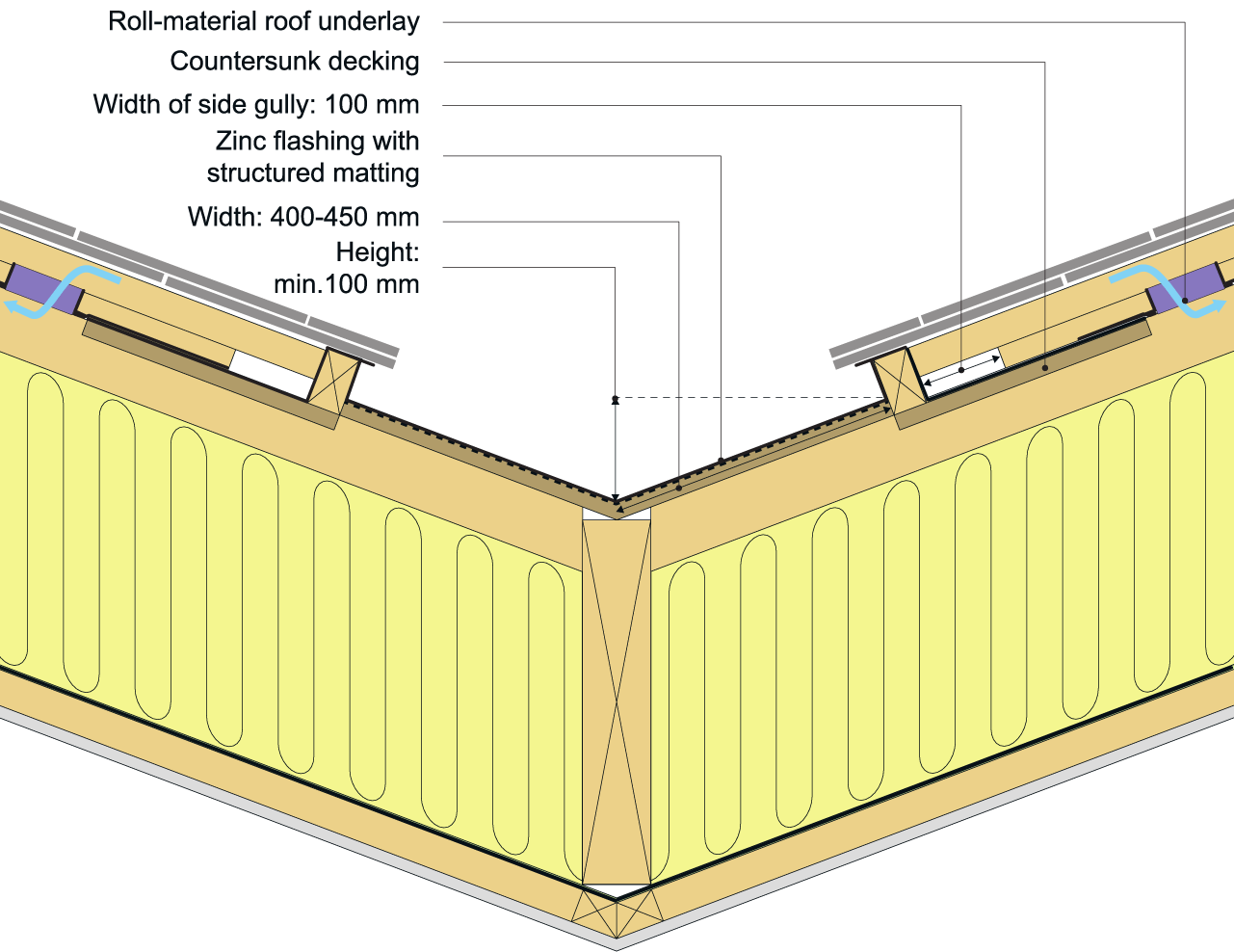

In a concealed valley, water from both roof covering and underlayment is drained into the valley as the underlayment (if used) is carried into and fixed to the valley flashing (made from e.g., zinc or aluminium). The concealed valley is currently the most commonly used type and is regarded as the safer of the two.

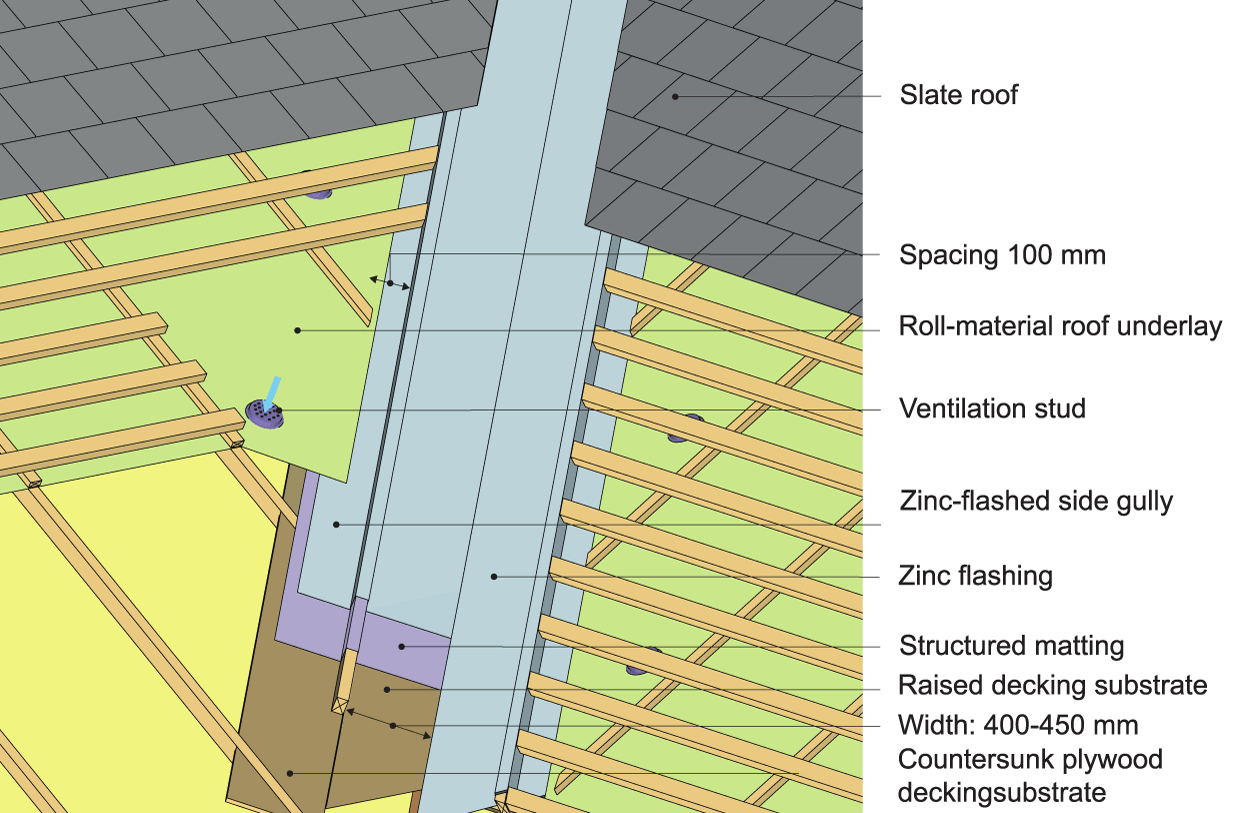

Raised valleys only receive water from the roof covering while water from the roofing underlayment (if fitted) must be discharged via side gullies (’secondary valleys’) on either side of the primary valley. Raised valleys are normally only used where special requirements apply to the roof (e.g., zinc roofs).

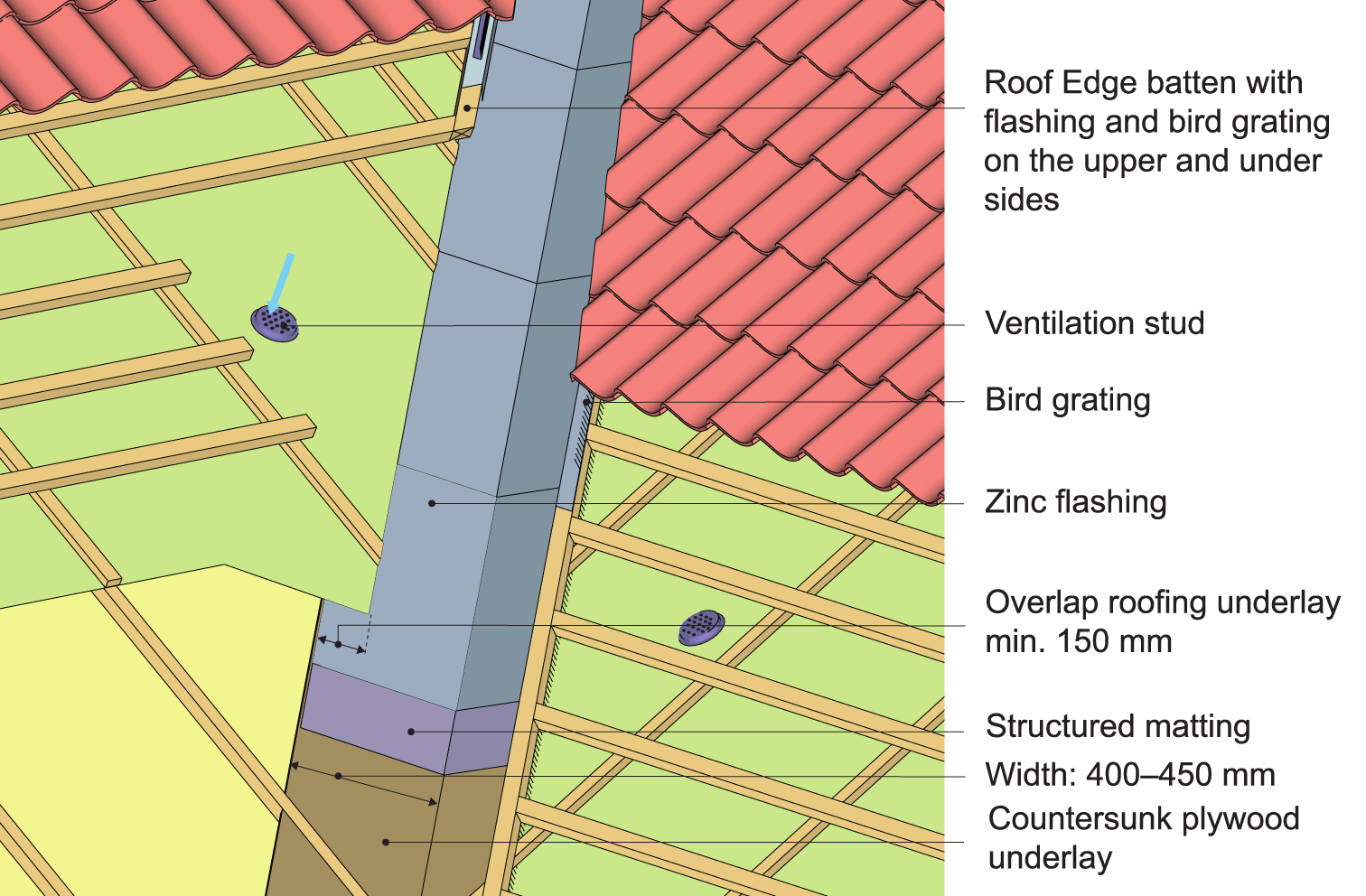

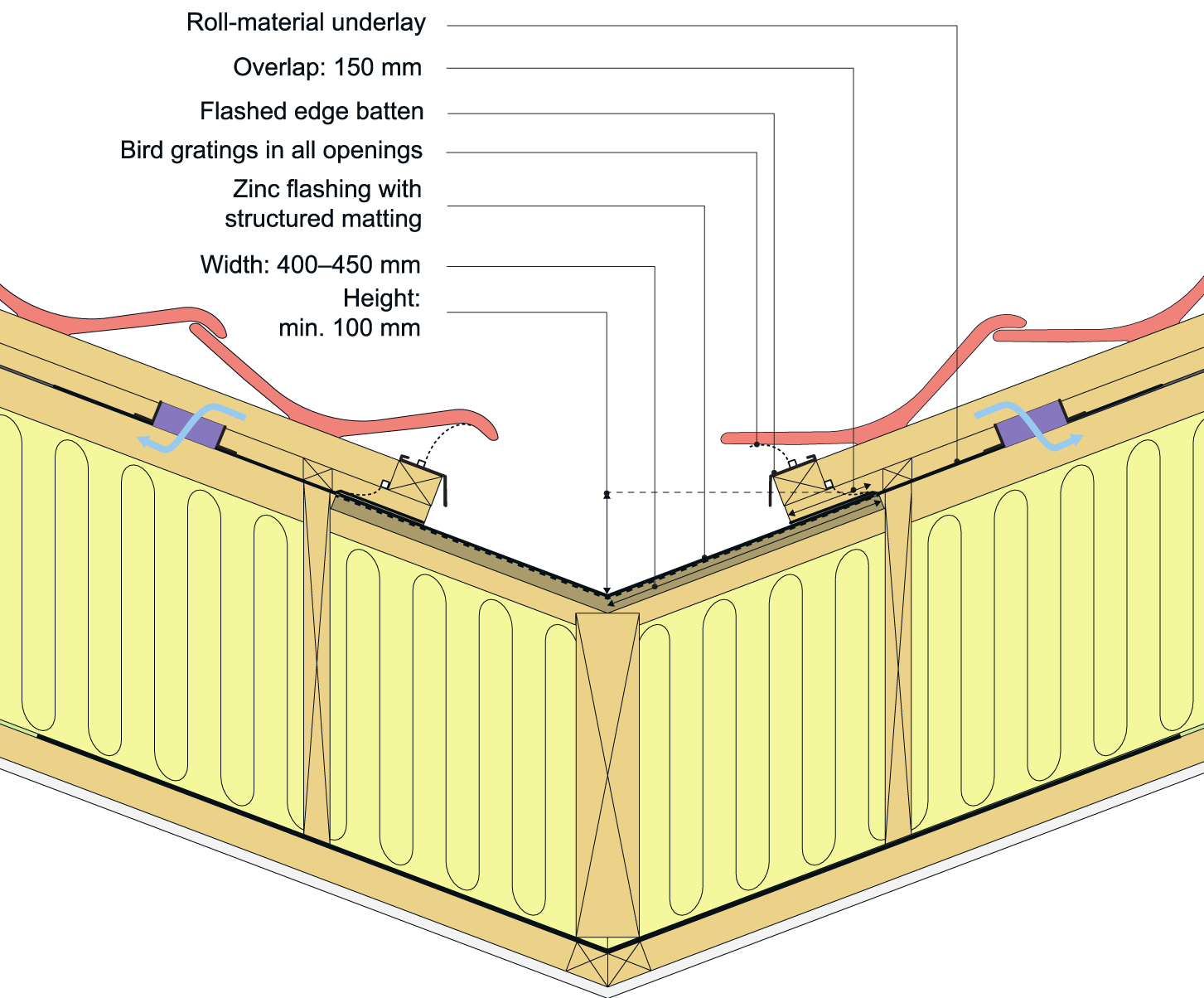

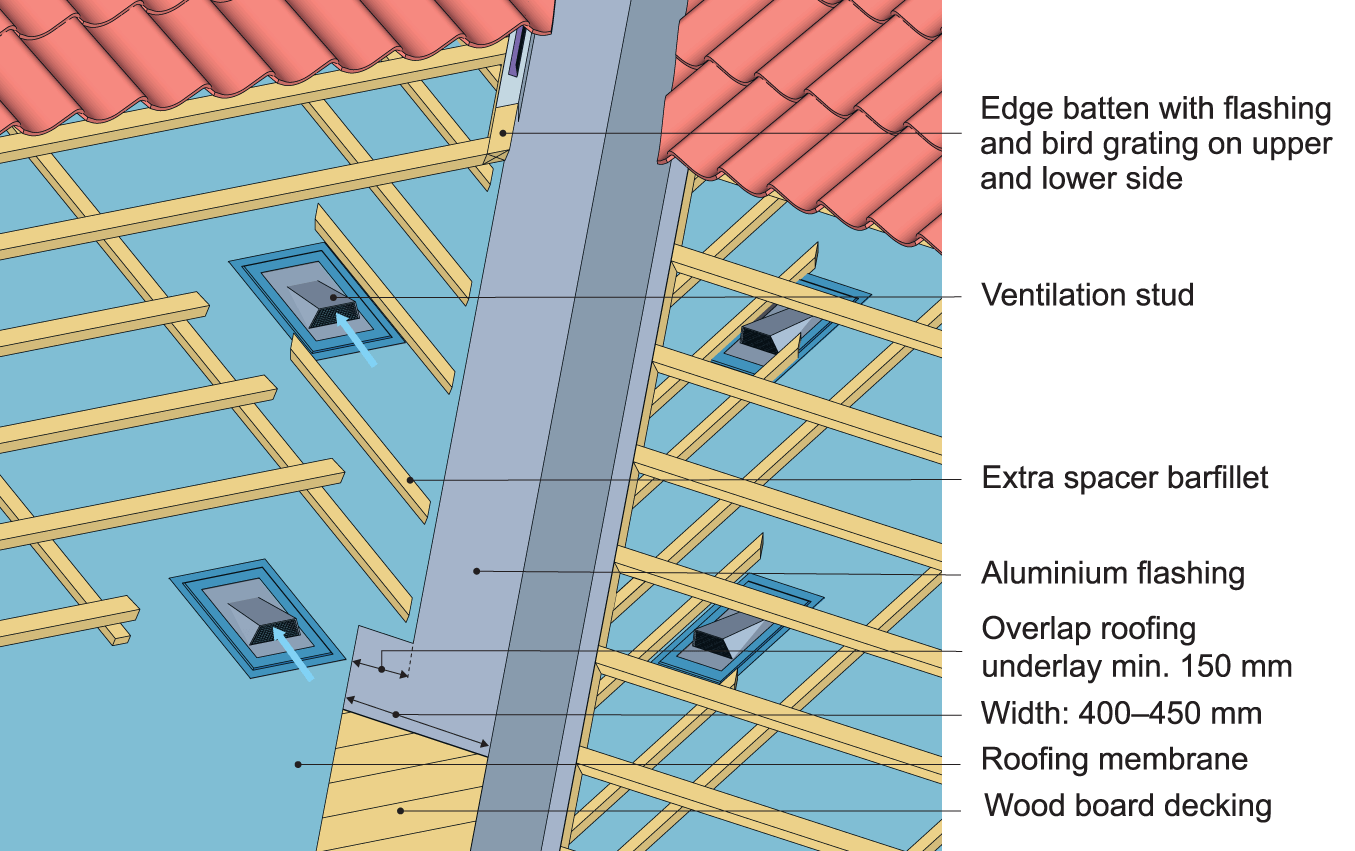

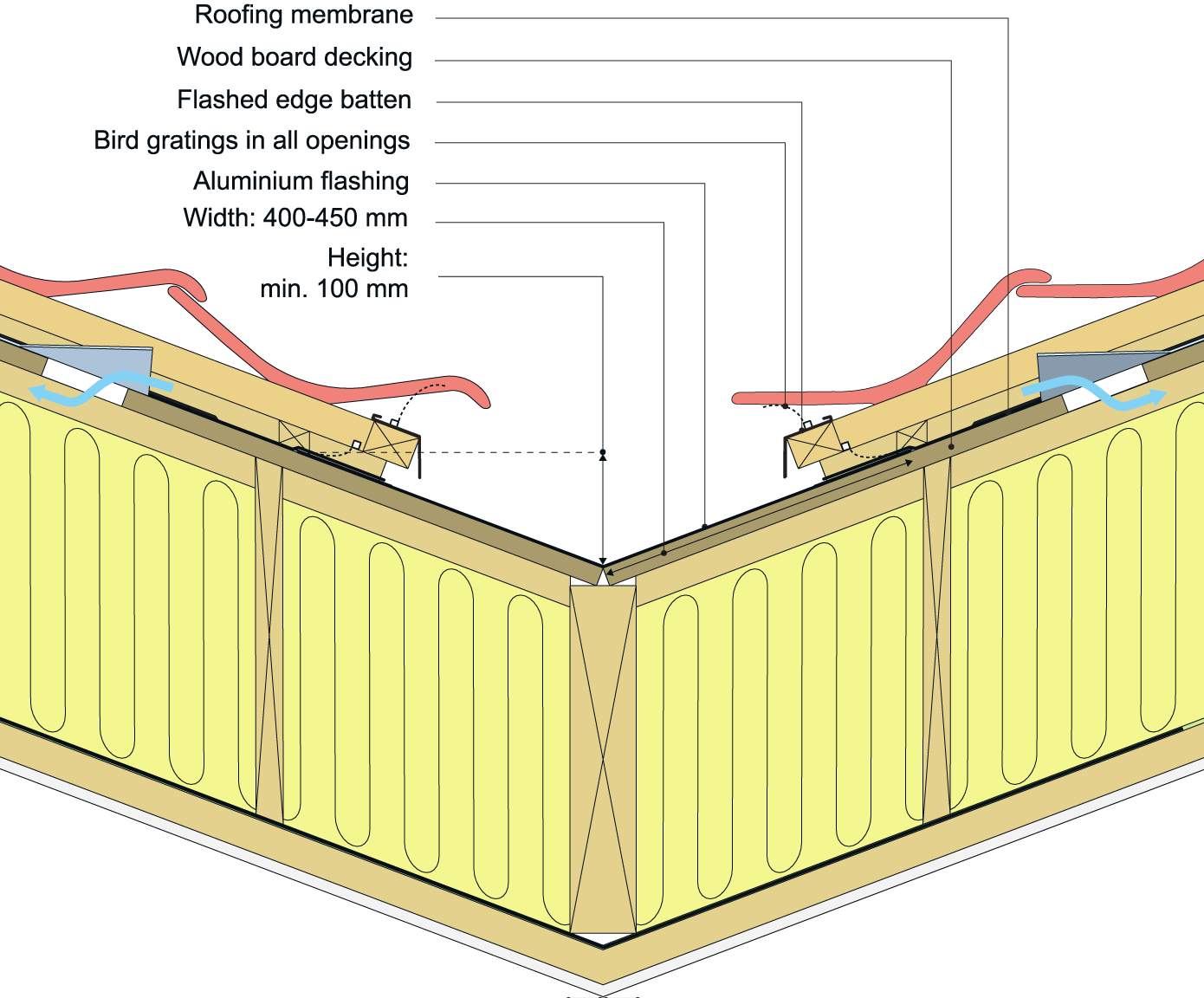

Valleys are normally installed on a plywood decking clad with zinc, aluminium, bituminous felt, or roofing foil (depending on the roof covering). The valley decking must be min. 400–450 mm wide measured outward on either side from the bottom of the valley. The spacing from the bottom of the valley to its upper edge should be min. 100 mm (i.e., the lower the slope of the valley or roof, the wider the valley should to be).

If roofing underlayment is used, it must be carried at least 150 mm over the zinc or aluminium flashing and must be sealed to the flashing (e.g., with one or two strips of butyl tape). In most cases, concealed valleys are preferable, so that the upper side of the firm decking is flush with the upper edge of the rafters (see Figure 205).

In vented roof assemblies, care must be taken to ensure that the valley does not impede ventilation and it would normally be necessary to establish roof vents in the roofing underlayment between the jack rafters.

If the valley is flashed with zinc on a plywood deck, structured matting must be fitted underneath the zinc.

Concealed Valley with Roll-Material Underlayment

Figure 205. An example of a concealed zinc valley with vented roofing underlayment of roll material. The valley should be 400–450 mm wide measured out from either side relative to the roof slope. The depth of the valley from the bottom to the top edge of the flashing should be min. 100 mm. The roofing underlayment is carried min. 150 mm over the zinc cladding in the valley and sealed with one or two strips of butyl tape. Roof vents are placed in the roofing underlayment in couple roofs to ensure adequate ventilation around the valley, and bird gratings are fitted to all openings between the valley and roof covering (see also Figure 71).

Valley with Firm Roofing Underlayment

Figure 206. An example of a concealed zinc valley with vented roofing underlayment of roll material.The valley should be 400–450 mm wide measured out from either side relative to the roof slope. The depth of the valley from the bottom to the top edge of the flashing should be min. 100 mm. Roofing underlayment is continued over the alu-cladding in the valley for a min. of 150 mm and sealed with one or two strips of butyl tape. Roof vents are placed in the roofing underlayment to ensure adequate ventilation around the valley in couple roofs and insect meshes are fitted to all openings between the valley and the roof.

Raised Valley with Roll-Roofing Underlayment

Figure 207. An example of a raised zinc valley structure with side gullies in slate roof and a vented roofing underlayment of roll material. The valley should have a depth from the bottom to the top edge of the flashing of min. 100 mm and a width of 400–450 mm measured out from either side relative to the roof slope. Valley and side gullies are executed in wood board or plywood. Side gullies are embedded between rafters and fixed to roof battens on rafters. The roofing underlayment is continued a min. of 50 mm over the zinc cladding inside gullies and sealed with one or two strips of butyl tape, for example. Roof vents are placed in the roofing underlayment in couple roofs to ensure adequate ventilation around the valley.

Raised Valley Without Roofing Underlayment

Figure 208. An example of a raised aluminium valley structure in a roof with a vented loft space and watertight roof covering (e.g., corrugated sheets or concrete tiles with taped joints). The valley should have a depth from the bottom to the top edge of the flashing of min. 100 mm and a width of 400–450 mm measured out from either side relative to the roof slope. Insect mesh is fitted to all openings between valley and roof coverings.

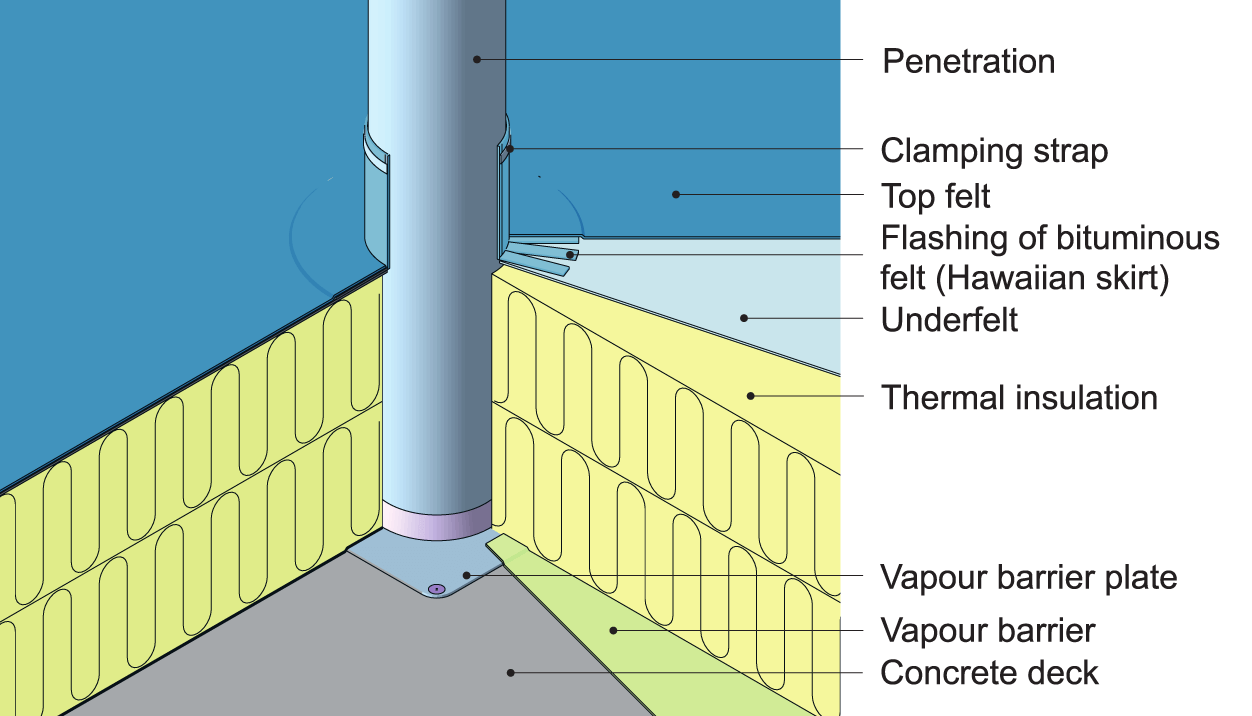

7.3 Roofs with Continuous Roof Covering

For flat roofs (roof slope < 10 °), a continuous roof covering in the form of a roofing membrane is normally used and the waterproofing is thus a one-step procedure (but executed with two layers in two-ply solutions). At all intersections and penetrations, flashings must be watertight at roof-covering level and airtight at vapour-barrier level (see Figure 209).

Figure 209. A diagram of the flashing around a penetration in a flat continuous membrane roof.

- Flashing penetrations in a cold roof.

- Flashing penetrations in a warm roof.

According to common practice, all flashings must be watertight up to 150 mm above the roof-covering level. For green roofs, however, the flashing height should be min. 200 mm, as such roofs tend to expand over time (see Section 5.11, Green Roofs).

Roof drainage must be executed so that water levels, even in the event of torrential downpours or blocked drains, will never stand higher than the flashings. This can be achieved by establishing emergency outlets from the roof (e.g., through kerbs) (see Section 2.2.4, Draining Flat Roofs).

Please note that fire safety regulations must be observed for penetrations in flammable insulation materials. The work must be carried out according to the rules for hot work (cf. DBI Vejledning 10, Del 1 – Varmt arbejde – Brandsikringsforanstaltninger (DBI Guidelines 10, Part 1 – Hot Work – Fire Protection Measures, Planning and Execution)) (DBI Fire and Security, 2008).

Penetrations are normally flashed on site in two principal ways:

- Flange flashing, where the roof covering finishes on a flange which is sealed to the penetration with a watertight joint. The flange must be wide enough to ensure watertight adhesion between flange and roofing membrane. The width should be min. 100 mm.

- The roof covering (or a suitable flashing) is extended up the penetration, ensuring watertightness at a height of min. 150 mm above roof-covering level.

Prefabricated flashings exist which can be integrated into the roof covering. Membrane solutions applied in liquid form can also be used in special circumstances. Bonded solutions are available for metal roofs and certain roofing foils, which are useful for renovations (e.g., where a new penetration is established in an existing roof). Such renovation solutions must be executed according to manufacturer's instructions and the usability of the solution should be documented.

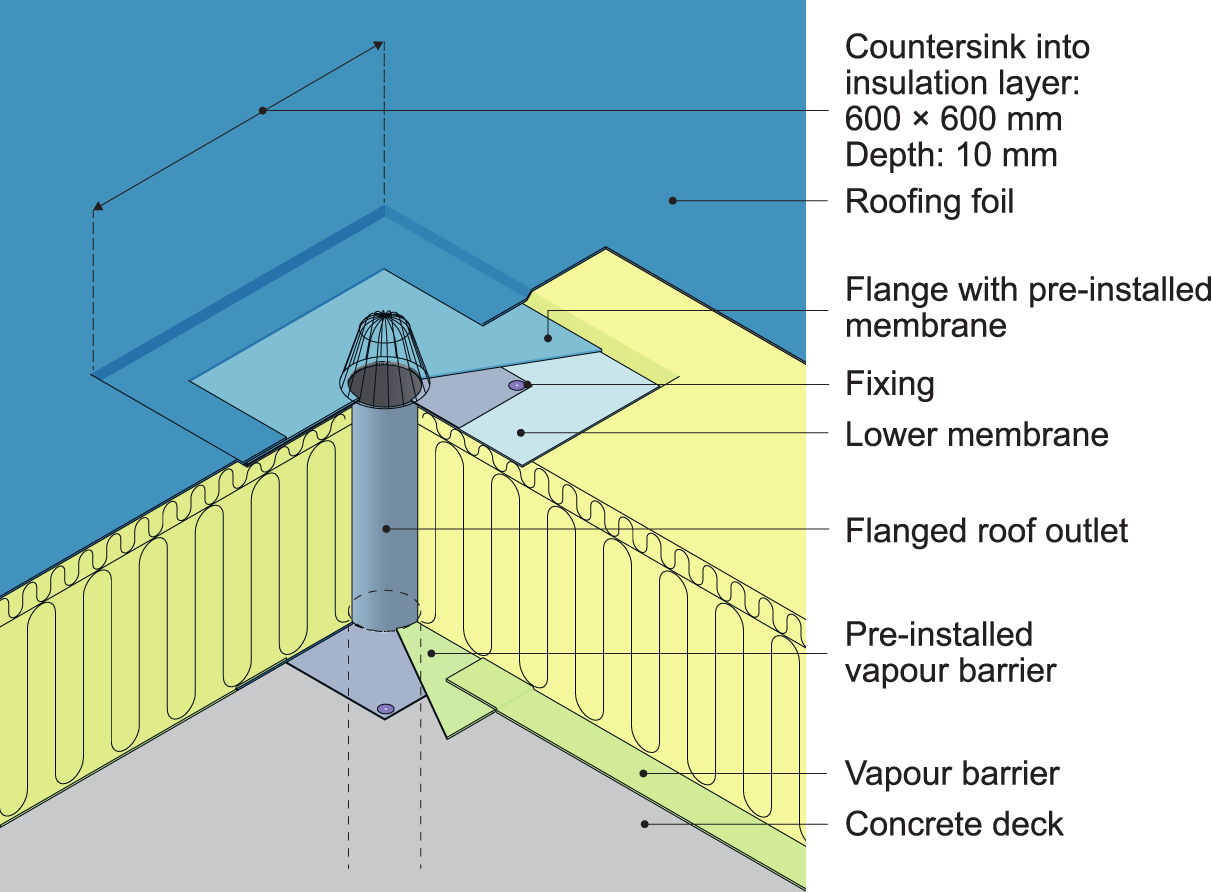

7.3.1 Flashing at Vapour-Barrier Level

For flat membrane roofs, the vapour barrier must be airtight at all points of intersection (e.g., ventilation ducts, soil stacks, and roof outlets).

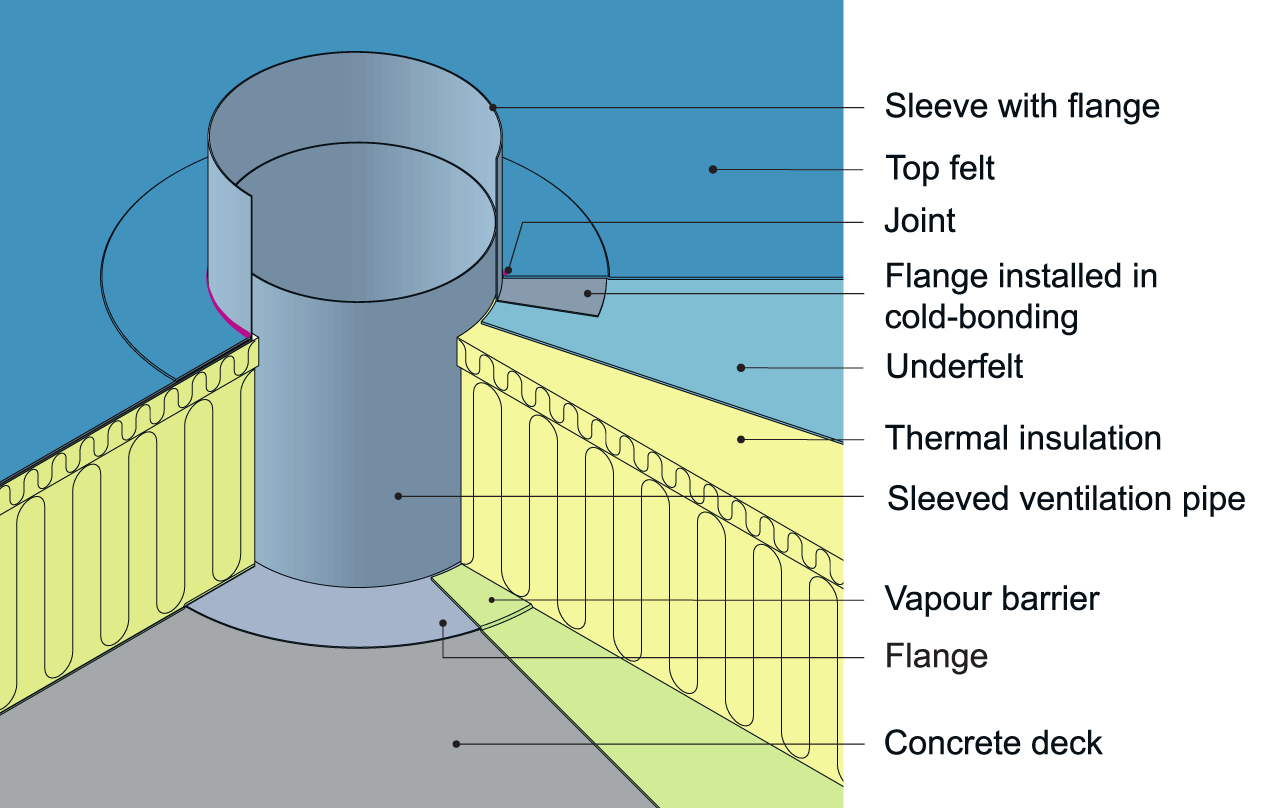

The vapour barrier (which in warm roofs normally consists of a roofing membrane) must be flashed by extending the membrane up the penetration by bonding or welding. Alternatively, a sleeve could be used or a so-called vapour barrier plate which is made of metal with a central hole covered with an elastic membrane (on the underside). The penetration can be passed through this plate (see Figure 210).

In some cases, ventilation ducts are supplied with pipe lead-in, flange, and a pre-installed membrane for the vapour barrier (which normally ensures good adhesion and tightness).

General guidelines for the use of vapour barriers in roofs are outlined in Section 2.1.2, Vapour Barriers in Roofs (see Section 7.2.1, Flashing at Vapour-Barrier and Underlayment Level).

Figure 210. An example of a vapour barrier plate for flashing at vapour-barrier level around a penetration (e.g., a roof outlet or soil stack, with a diameter of up to 150 mm). On the underside, the vapour barrier plate has a flexible rubber membrane with a hole slightly smaller than the pipe passing through it. When the vapour barrier plate is pulled down over the pipe, the rubber membrane will stretch tightly around it, extending slightly up around the pipe on the upper side. It must be fitted exclusively with cold-bonding and screws as the rubber will not tolerate the heat from a gas burner (see Figure 212).

7.3.2 Flashing Penetrations

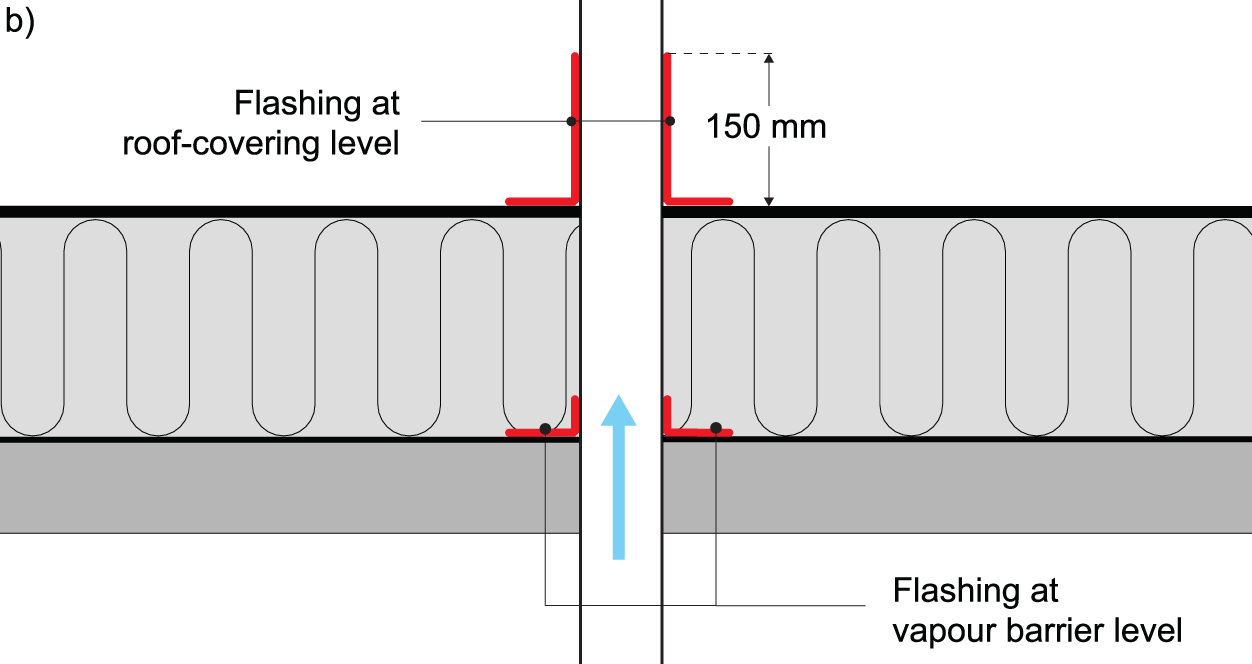

Penetrations for ventilation ducts and soil stacks in flat roofs with a bituminous felt covering are normally flashed using a flange welded to the pipe or duct. Using roofing foil, the flashing can be made to extend up around the duct. Several prefabricated stainless-steel flashings with a pre-installed roofing membranes are available. These provide a high degree of watertightness and facilitate roof work.

If the flange has not been fully welded to the penetration, but instead point-welded and sealed, when welding the bituminous felt care must be taken not to damage the sealing joint. Either a distance of 50 mm should be maintained from the joint or pipe, or the pipe should be cold-bonded. If the roofing membrane has been continued in, sealant is applied between the roofing membrane and pipe, using a suitable membrane adhesive or caulking compound (see Figure 211).

Flange-flashing is suitable for both bituminous felt and roofing foil. Flashings extending up the penetration are best carried out using roofing foil but can also be carried out using bituminous felt on both square and round penetrations by means of a so-called ’Hawaiian skirt’. However, ‘Hawaiian skirts’ are difficult to implement safely (see Figure 212).

It is advisable to carry out flange-flashing using a pre-installed roofing membrane because the metal surfaces can then be degreased and primed efficiently, which will ensure a watertight and strong joint.

Figure 211. An example of flange-flashing for a large penetration (e.g., a vent pipe) in a roof covering of two-ply bituminous felt. The penetration is carried out via a two-part prefabricated element with a welded flange at both roof-covering and vapour-barrier level where the upper part is moveable to adapt to the thickness of the thermal insulation. Flashing must be tight at both vapour-barrier and roof-covering level. The flashing height must be min. 150 mm above the roof covering.

Figure 212. An example of flashing a small round penetration in two-ply bituminous felt covering where the felt extends up the penetration via a ’Hawaiian skirt’. Flashing at vapour-barrier level is shown with a vapour barrier plate (see Figure 210). The flashing height must be min. 150 mm above the roof covering.

Figure 213. An example of flashing around a soil stack using one-ply roofing foil with a roofing-foil sleeve.

Figure 214. An example of two-ply bituminous felt flashing of a penetration for a soil stack with rubber flashing sleeve under the top felt and a flexible rubber sleeve around the roof covering intersection.

7.3.3 Flashing Roof Outlets

The installation of roof outlets in flat roofs is relative to the type of roofing membrane used. For roofs with a foil covering, both stainless-steel and plastic roof outlets can be used while, for bituminous felt roofs, only stainless-steel outlets can normally be used.

The roof outlets are ‘sumped’ approx. 10 mm into the deck, preventing the flashings from forming a bank around the outlet which would create a depression next to the outlet.

Figure 215. Examples or installation of roof outlets with flange and pre-installed membrane in warm roof with concrete deck.

- Solution with two-ply bituminous felt covering

- Solution with one-ply roofing foil.

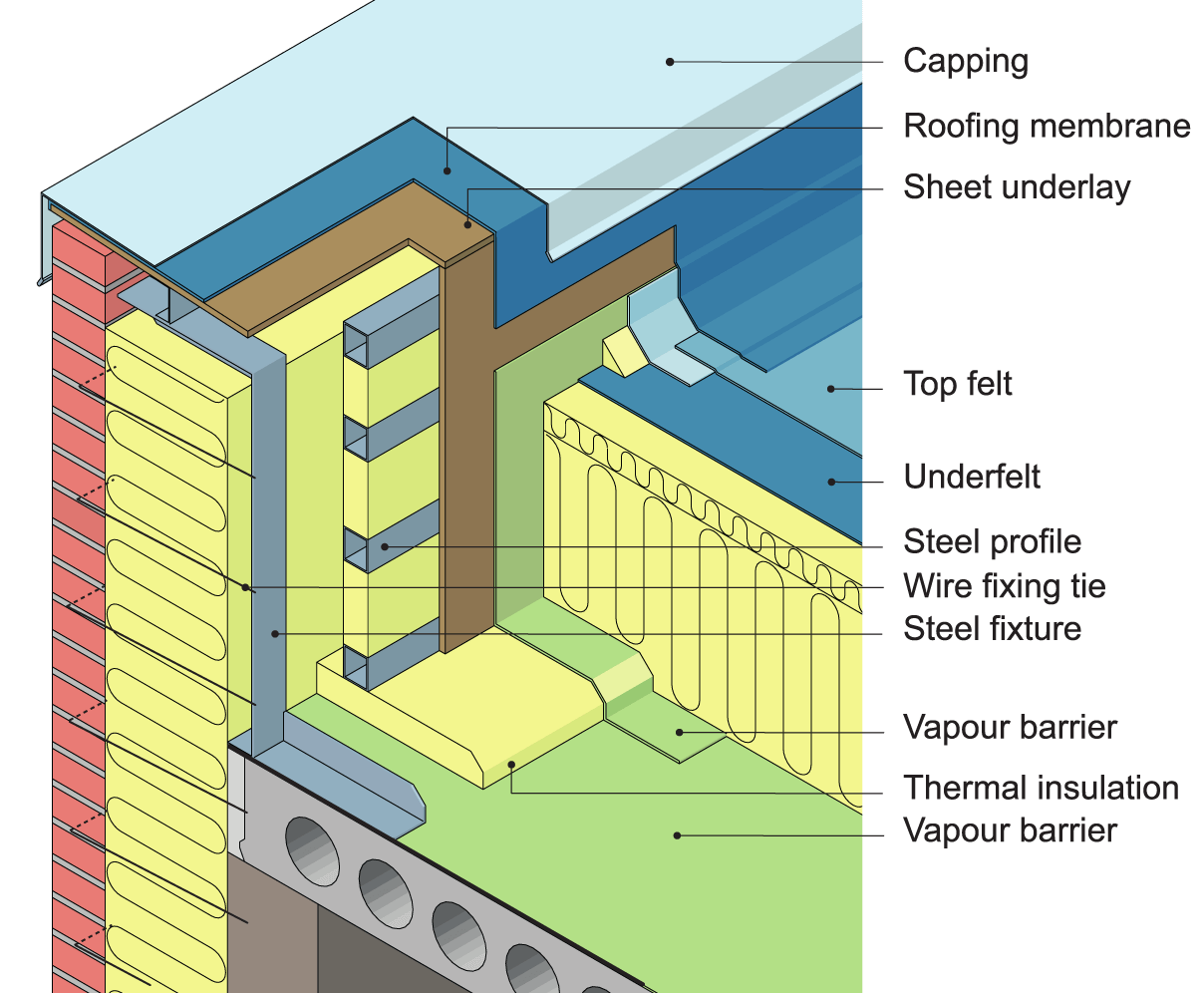

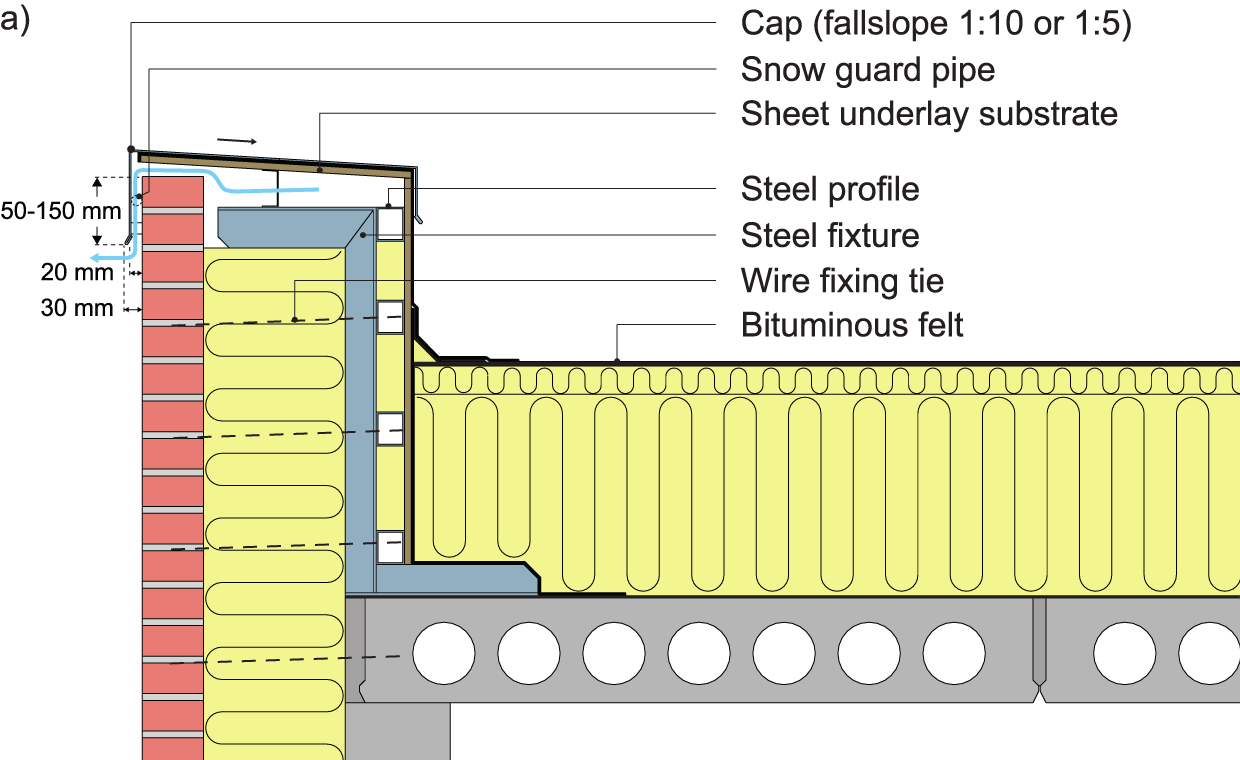

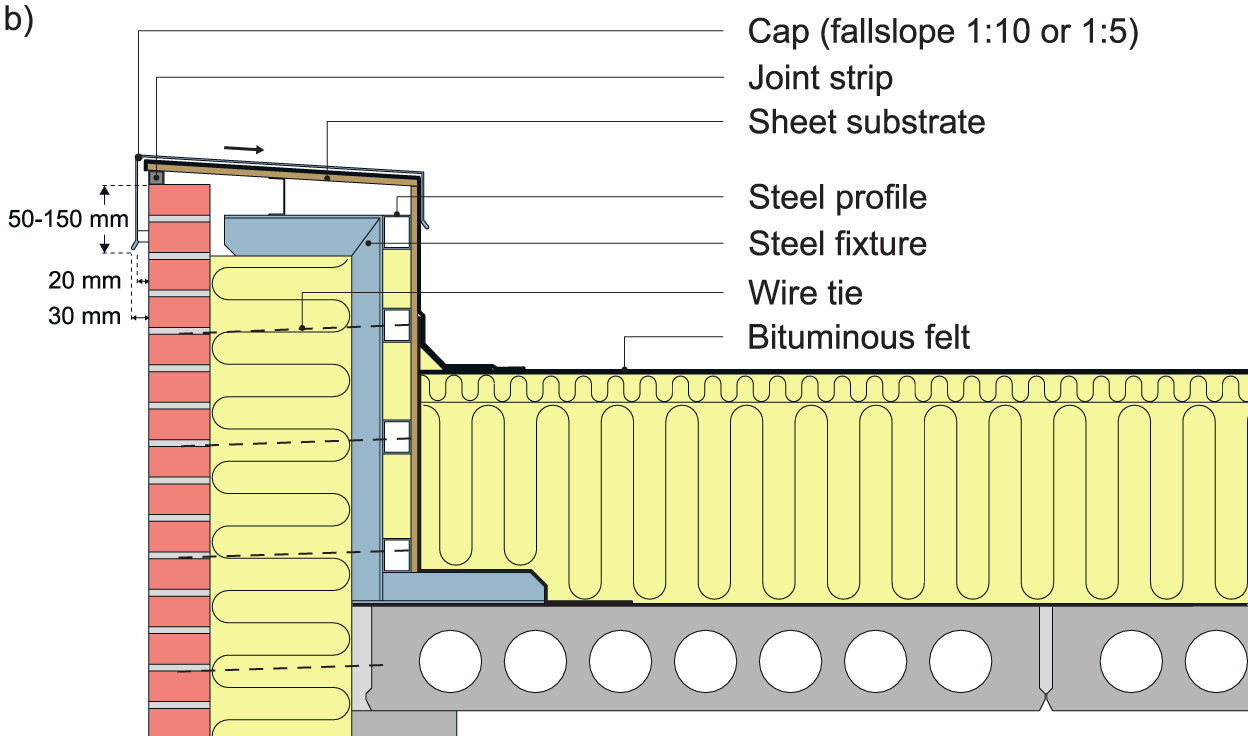

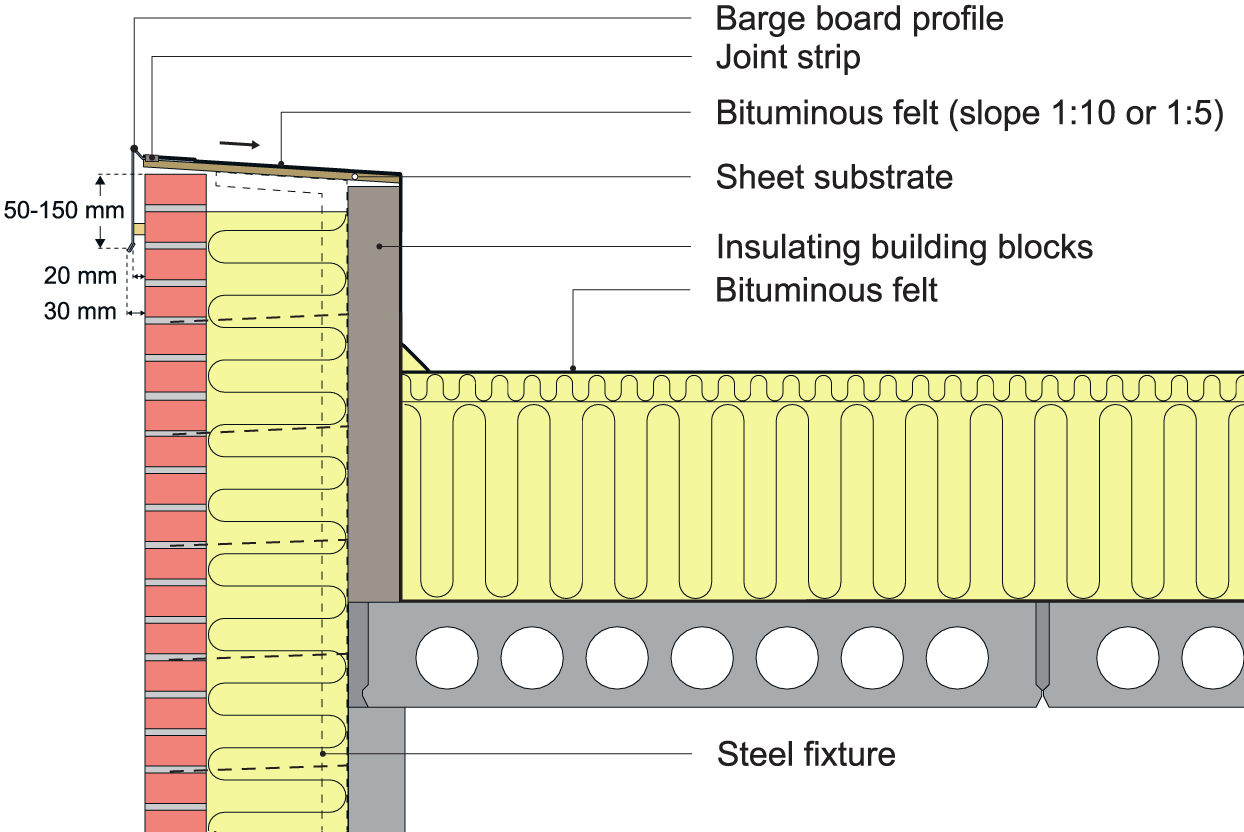

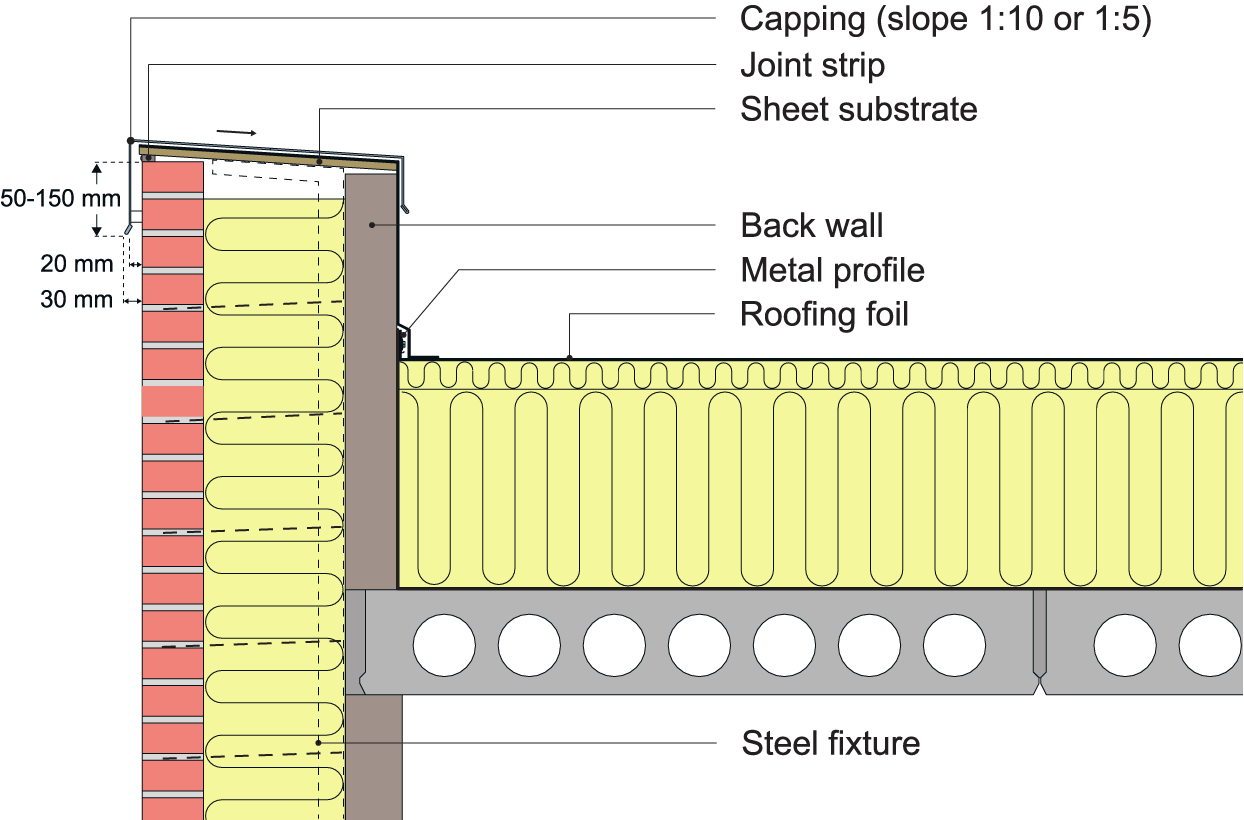

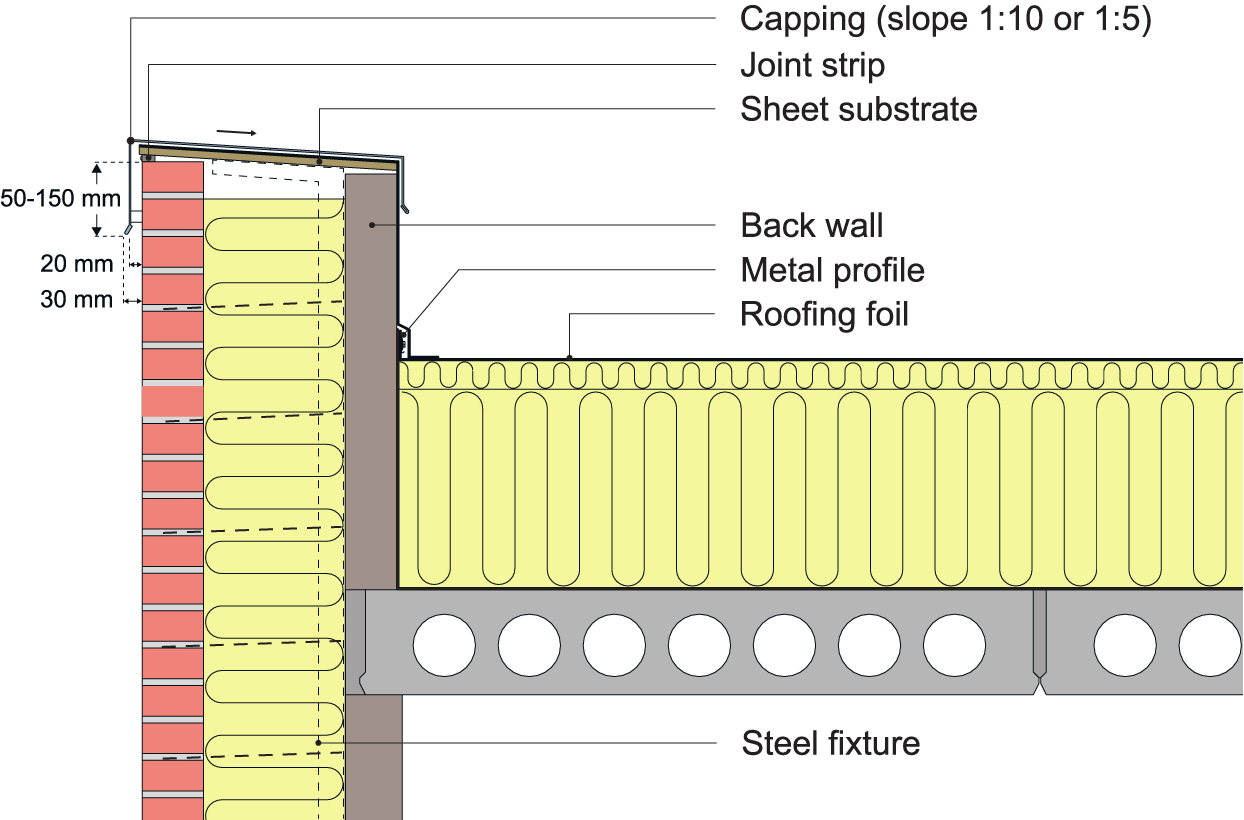

7.3.4 Flashing Parapet Walls

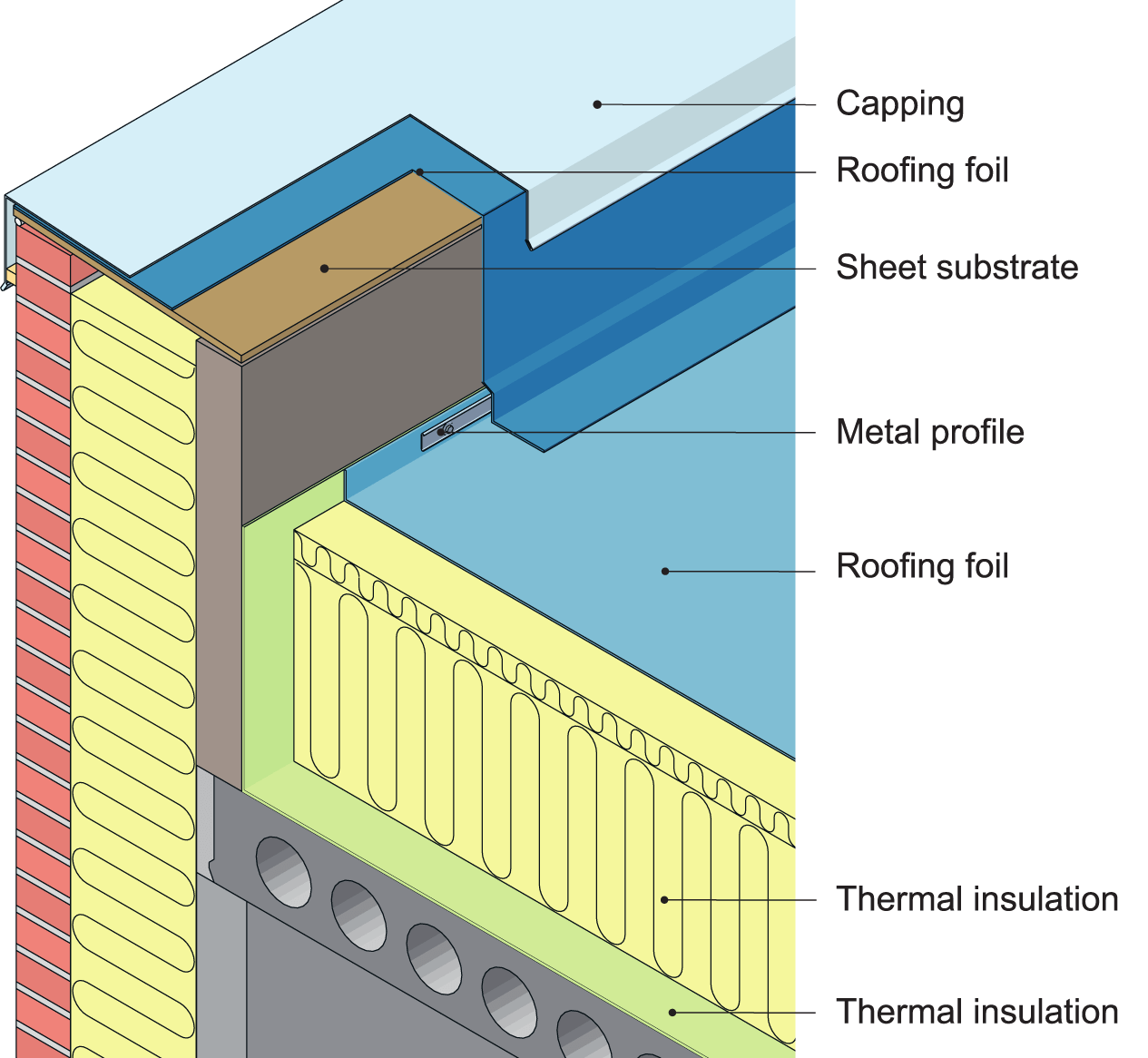

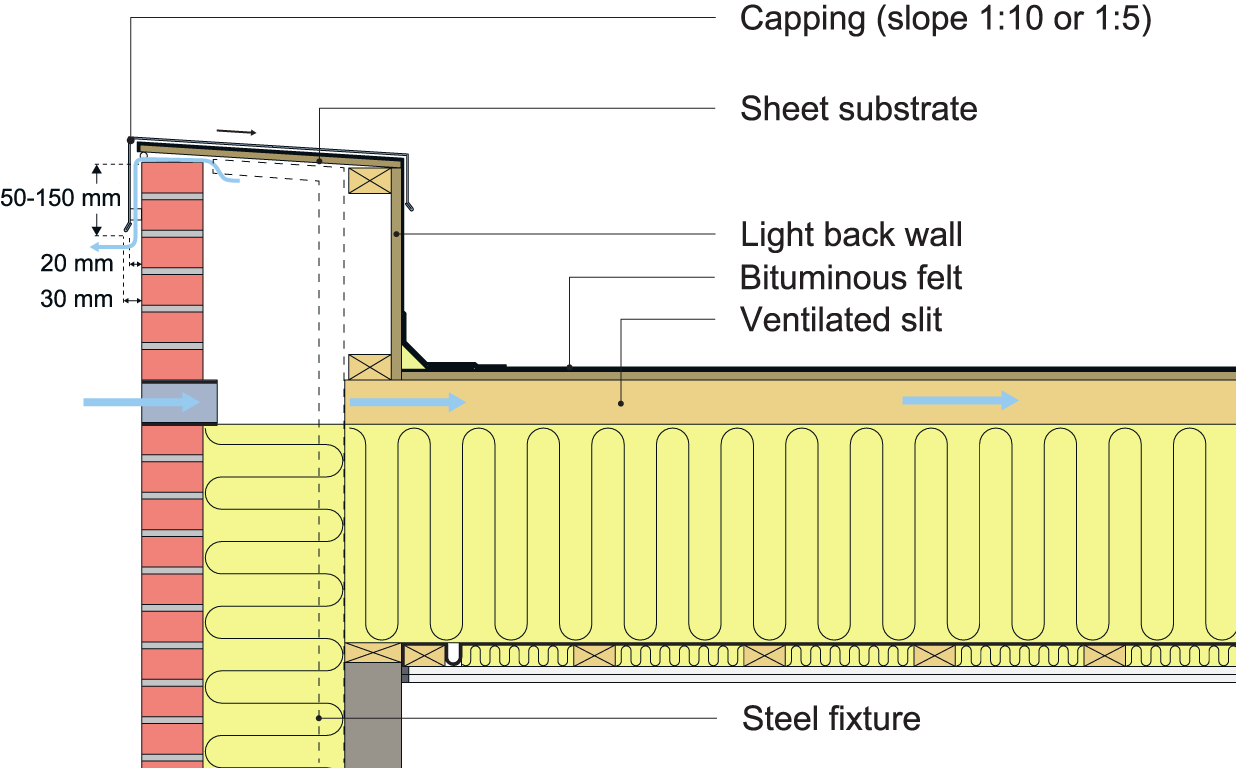

When flashing parapet walls at intersections with flat membrane roofs, the roofing membrane is normally continued to the very edge of the parapet wall which is then flashed using aluminium or zinc coping caps.

The height of the front panel of the coping cap must be adapted to the amount of rain and wind to which the facade is exposed. The height of the panel and thus the overlap with the front wall or façade is vital to whether driving rain will penetrate behind the flashing. The required height of overlap between the lower edge of the panel (drip nose) and the top edge of the front wall or facade can be determined using Table 27.

The coping cap must have a fall towards the roof surface of ideally 1:5 and no less than 1:10. The distance from the panel’s drip nose to the facade must be min. 30 mm. These measures are intended to prevent any discolouring of the facade. The distance between panel and front wall must be min. 20 mm.

Table 27. Required height of overlap between the lower edge of the coping cap (drip nose) and the upper edge of the front wall/facade when flashing parapet walls relative to terrain category and the height of the parapet above ground level.

Height of Overlap [mm] | |||

|---|---|---|---|

Terrain category | Height of parapet above ground level < 10 metres | Height of parapet above ground level ≥ 10 metres | |

I | 100 | 150 | |

II | 100 | 100 | |

III | 50 | 100 | |

IV | 50 | 50 | |

Parapet flashings can also be executed without coping caps if a barge board is used instead. The amount of overlap when using barge boards follows the rules outlined in Table 27.

Roofing foils are available for flashing parapet walls without coping caps or barge boards. Solutions without coping caps or barge boards must be installed according to manufacturer instructions.

Sheet underlay (and possibly the sheeting backside) should be cement particle board or a similar moisture-resistant material. If the top of the parapet wall is vented, plywood underlay can be used.

General guidelines for flashing roofing membranes to adjoining building parts are outlined in Section 5.7.7, Details – Roofing Membranes.

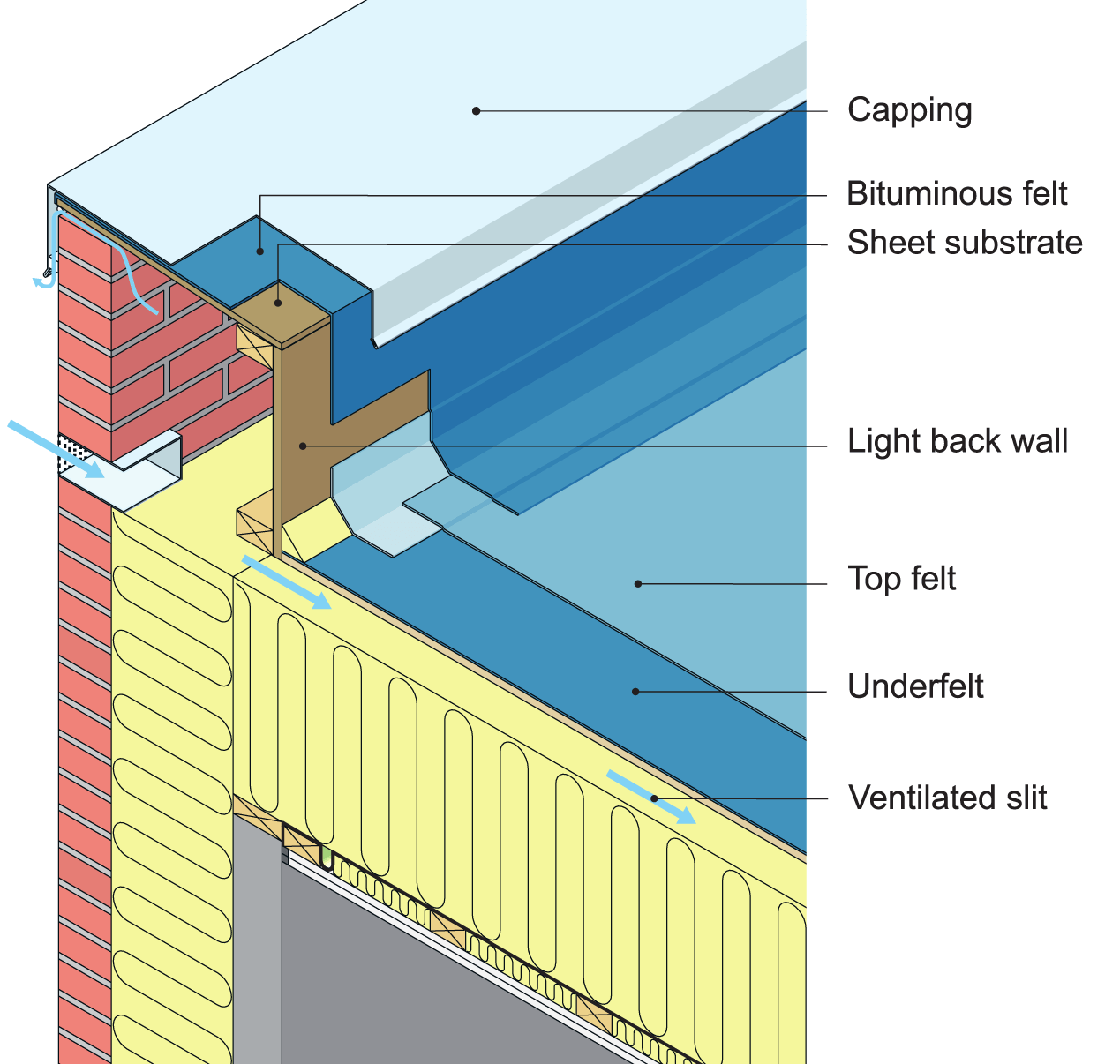

Examples of parapet-to-wall flashing are shown in Figures 216–222

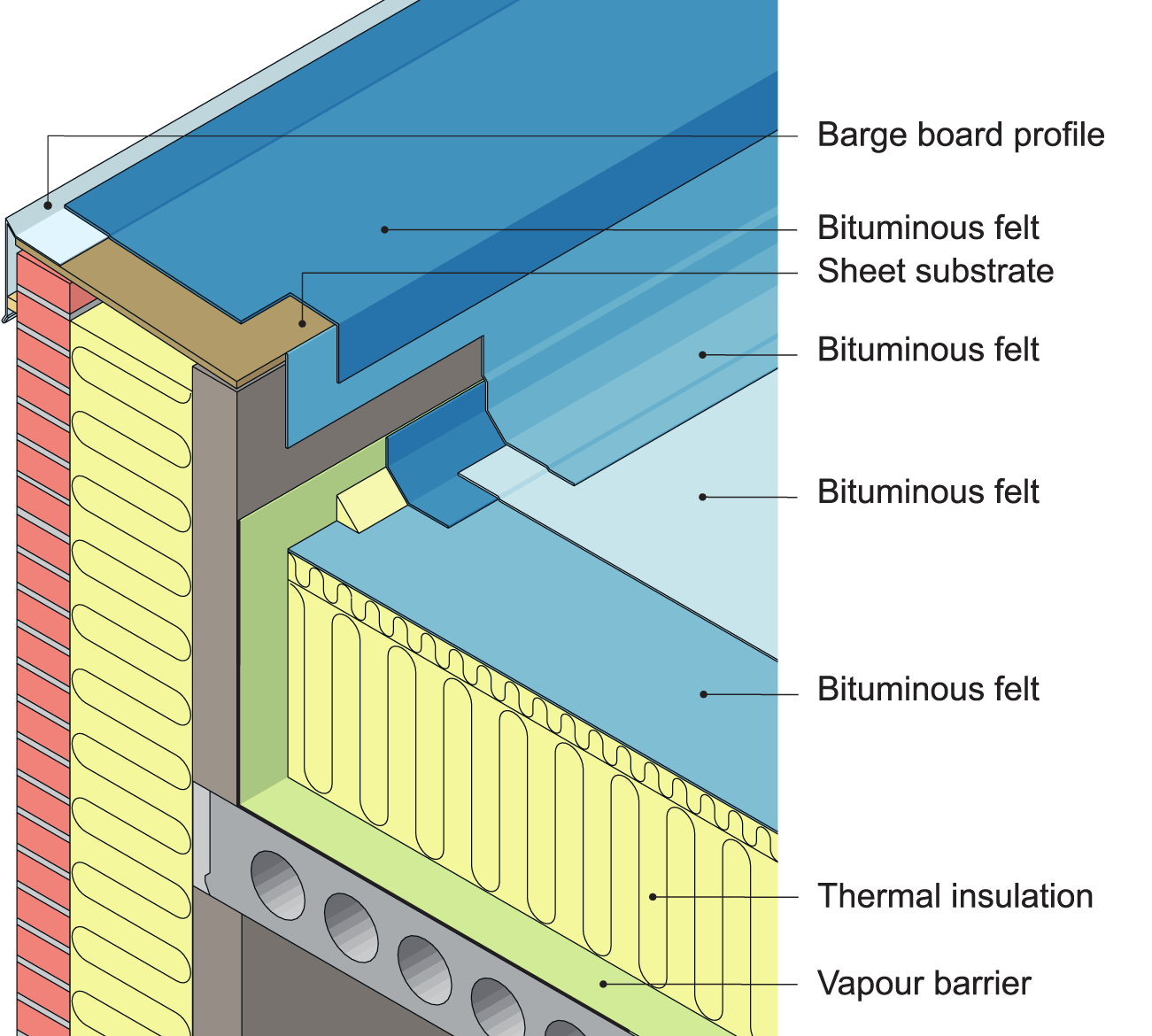

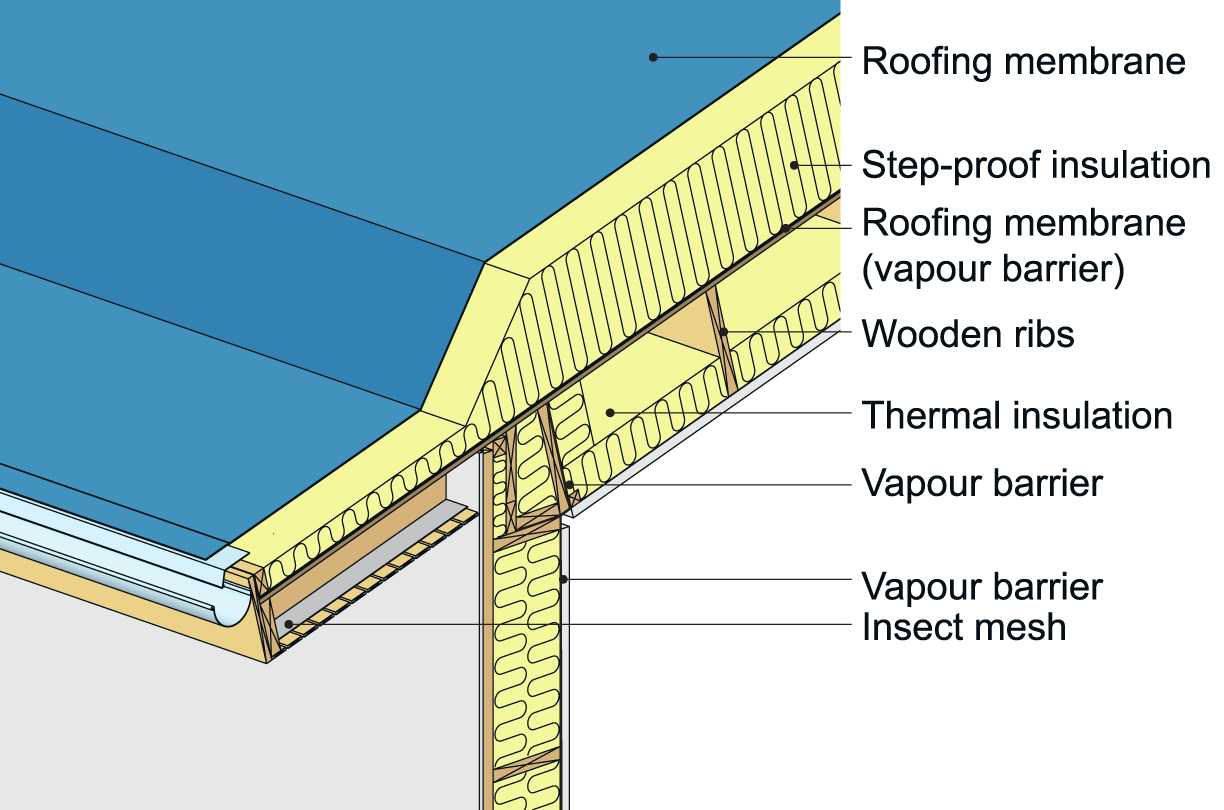

Figure 216. An example of flashing around a vented parapet at the intersection of a coping cap and a flat warm roof with a covering of two-ply bituminous felt. The parapet is fixed to the supporting steel structure on the concrete deck and has a panelled back wall (see also Figure 217a).

Figure 217. Examples of flashing at the intersection of (a) a vented parapet wall and non-vented parapet wall and (b) between a vented parapet wall and a flat warm bituminous felt roof where the parapet has a panelled back wall and is fixed to a supporting steel structure on the concrete deck. The back panel should be moisture resistant (e.g., made from cement particle board).

- The sealing joint is a two-step procedure with a snow guard pipe behind the front edge of the coping cap. The parapet is also vented longitudinally.

- The sealing joint is executed as a modified two-step procedure with expanding sealing strips between the front wall or façade and the underlay sheet.

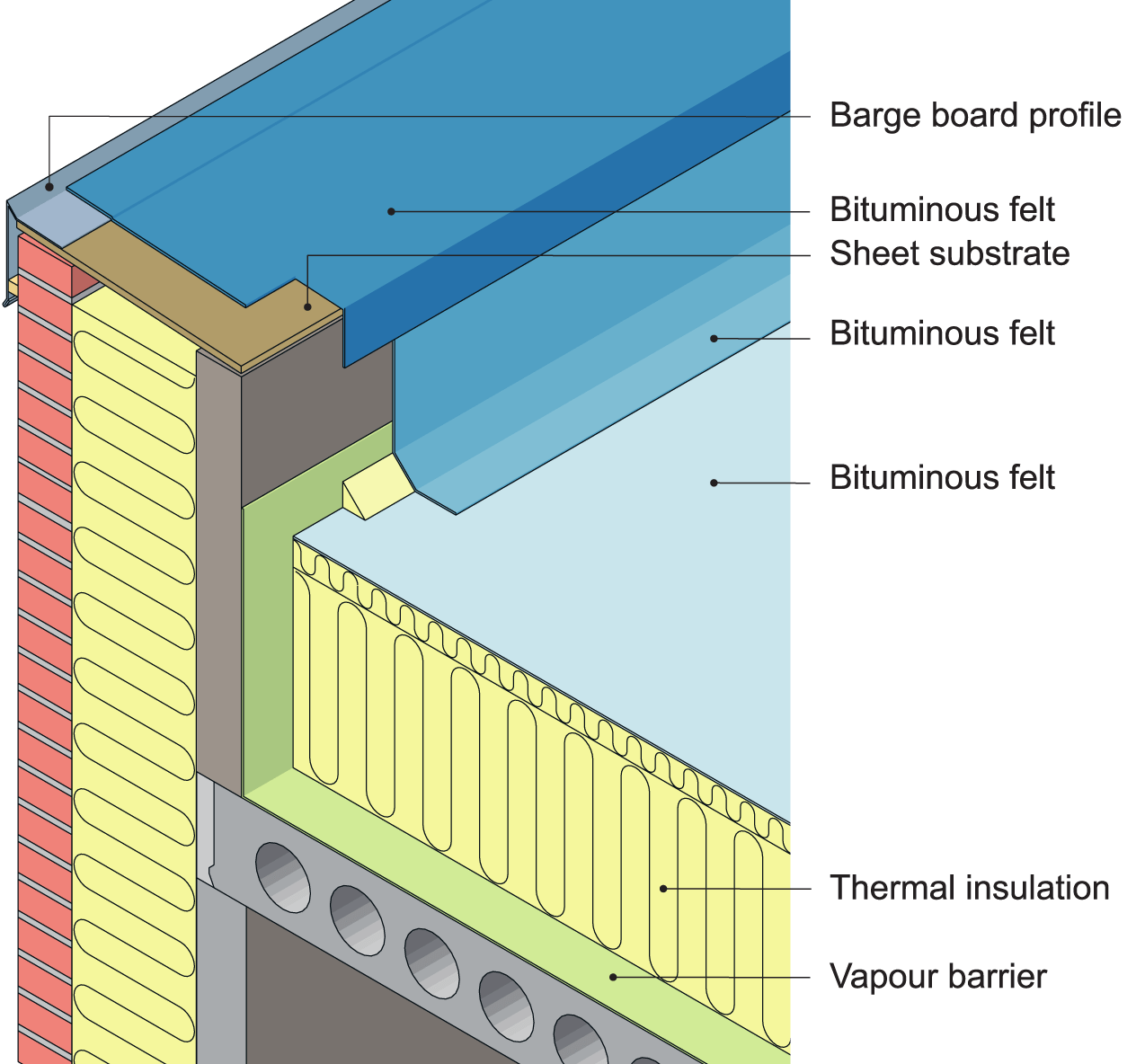

Figure 218. An example of flashing at the intersection of a non-vented parapet wall with barge board profile and a flat warm roof with two-ply bituminous felt covering. The back wall consists of isolating building blocks. The joint between vapour barrier and bituminous felt must be tight.

Figure 219. An example of barge-board profile flashing of a non-vented parapet wall at the intersection with a flat warm roof with a one-ply covering of bituminous felt where the back wall consists of insulating building blocks (e.g., expanded clay aggregate). The structure is vented longitudinally. The joint between vapour barrier and bituminous felt must be tight.

Figure 220. An example of flashing at the intersection of a non-vented parapet wall with coping cap and a flat warm roof with roofing foil covering. The back wall consists of insulating building blocks (e.g., expanded clay aggregate). The joint between vapour barrier and roofing foil must be tight

Figure 221. An example of flashing at the intersection of a non-vented parapet with a coping cap and a warm roof with roofing foil covering. The back wall consists of insulating building blocks (e.g., expanded clay aggregate). The joint between vapour barrier and roofing foil must be tight.

Figure 222. An example of flashing at the intersection of a vented parapet wall with coping cap and a cold vented roof with two-ply bituminous felt covering. The back wall is a light panel-clad structure. Openings are fitted with insect mesh. This example can also be used for roofs with a covering of one-ply bituminous felt or roofing foil (see Figure 219).

7.3.5 Flashing the Eaves

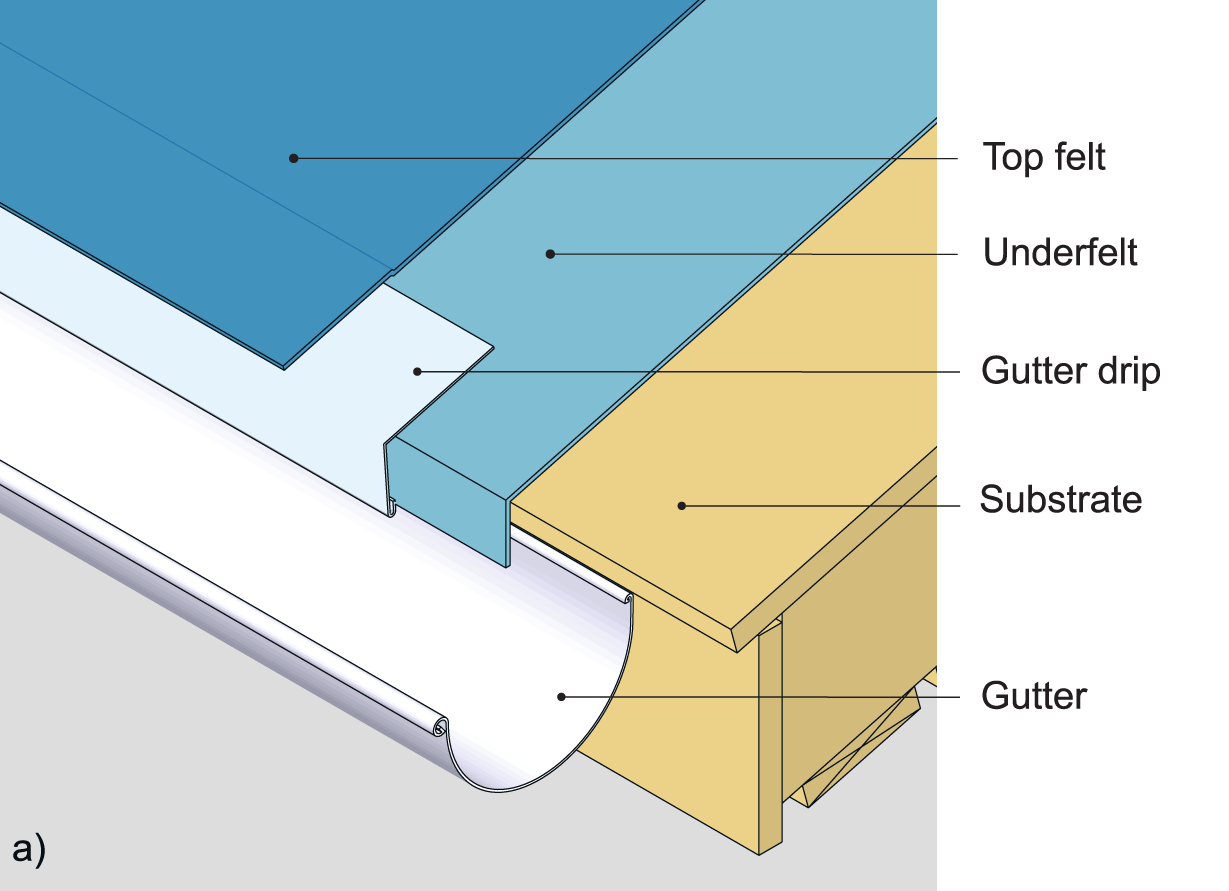

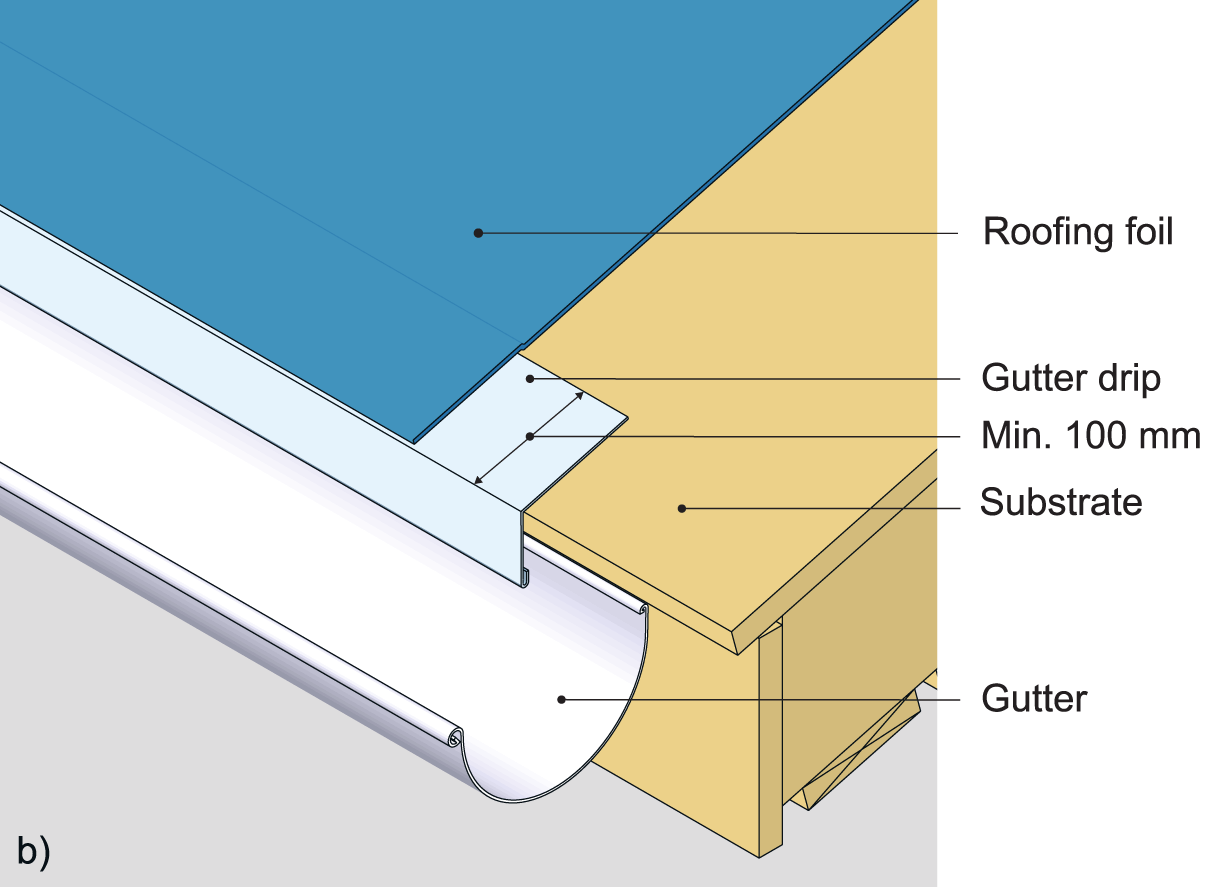

If a membrane roof is terminated at the eaves with falls to the gutter, cleat-edge flashing is used with bituminous felt or roofing foil.

The cleat-edge flashing should be aluminium or there will be a risk of corrosion and discolouring from acid rain or from the release of chemicals from the roofing membrane.

In roofs with an overhang, the roof covering may experience a powerful decrease in temperature at night during the spring and autumn months due to radiant emissions to the atmosphere. This may lead to moisture absorption in the decking underside, especially near to an overhang, because the relative humidity rises when the temperature drops. To avoid black mould, mould-proof plywood should be used in the overhang. Alternatively, 25 mm non-flammable thermal insulation may be used on top of the plywood, thereby raising the temperature of the plywood sheet (see Figure 223).

Figure 224 shows an example of how to flash an eave with a gutter in one-ply and two-ply roof covering.

Figure 223. An example of a roof overhang of wood-based roofing slab in a warm roof assembly. Anti-condensation insulation (in the form of a thin layer of thermal insulation) has been installed on the upper side of the plywood in the overhang to avoid black mould on the underside of the plywood.

Figure 224. Examples of eave flashing using cleat-edge flashing and bituminous felt.

- Eave flashing with cleat-edge flashing and a covering of two-ply bituminous felt. The underfelt is installed prior to the cleat-edge flashing.

- Eave flashing with cleat-edge flashing and roofing foil covering. The cleat-edge flashing must extend for a min. of 100 mm up the roof covering to ensure close adhesion, otherwise a horizontal cant strip must be fitted.

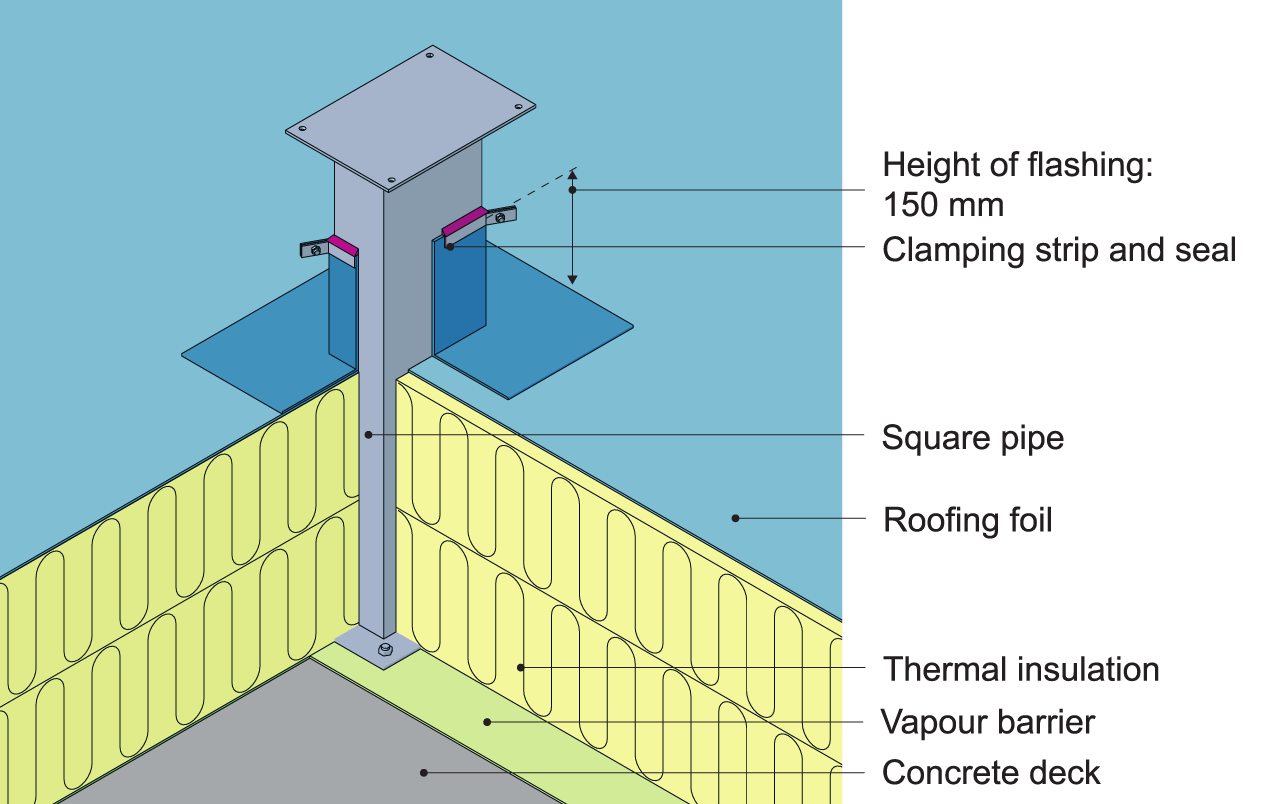

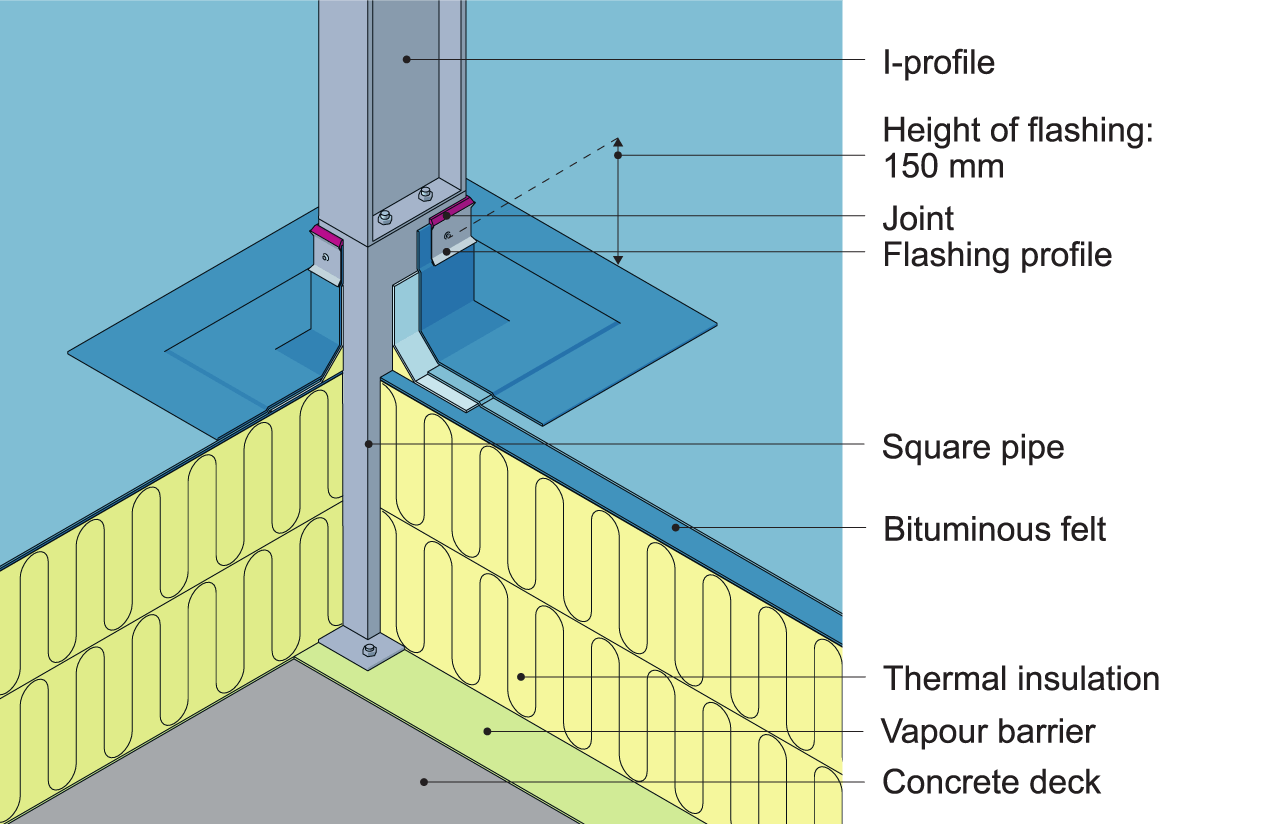

7.3.6 Flashing Stands and Bearings

Ventilation systems (and similar systems) placed on the roof must be flashed at the stands and bearings penetrating the roofing membrane when fixing them to the roof.

Systems and installations often have stands with a panel intended for fixing. In this case, the area under the panel must be flashed and the flashing must be fixed to the roof covering. All bearings must be executed as round or square pipes, as it is impossible to flash tightly around I-profiles (and other atypical shapes).

Figures 225 and 226 show examples of flashing at bearing intersections for installations on warm roofs with a membrane covering.

Figure 225. An example of bearing flashing on a warm roof with foil covering.

Figure 226. An example of flashing around a square pipe as a bearing for an I-profile in a warm roof with two-ply bituminous felt covering.

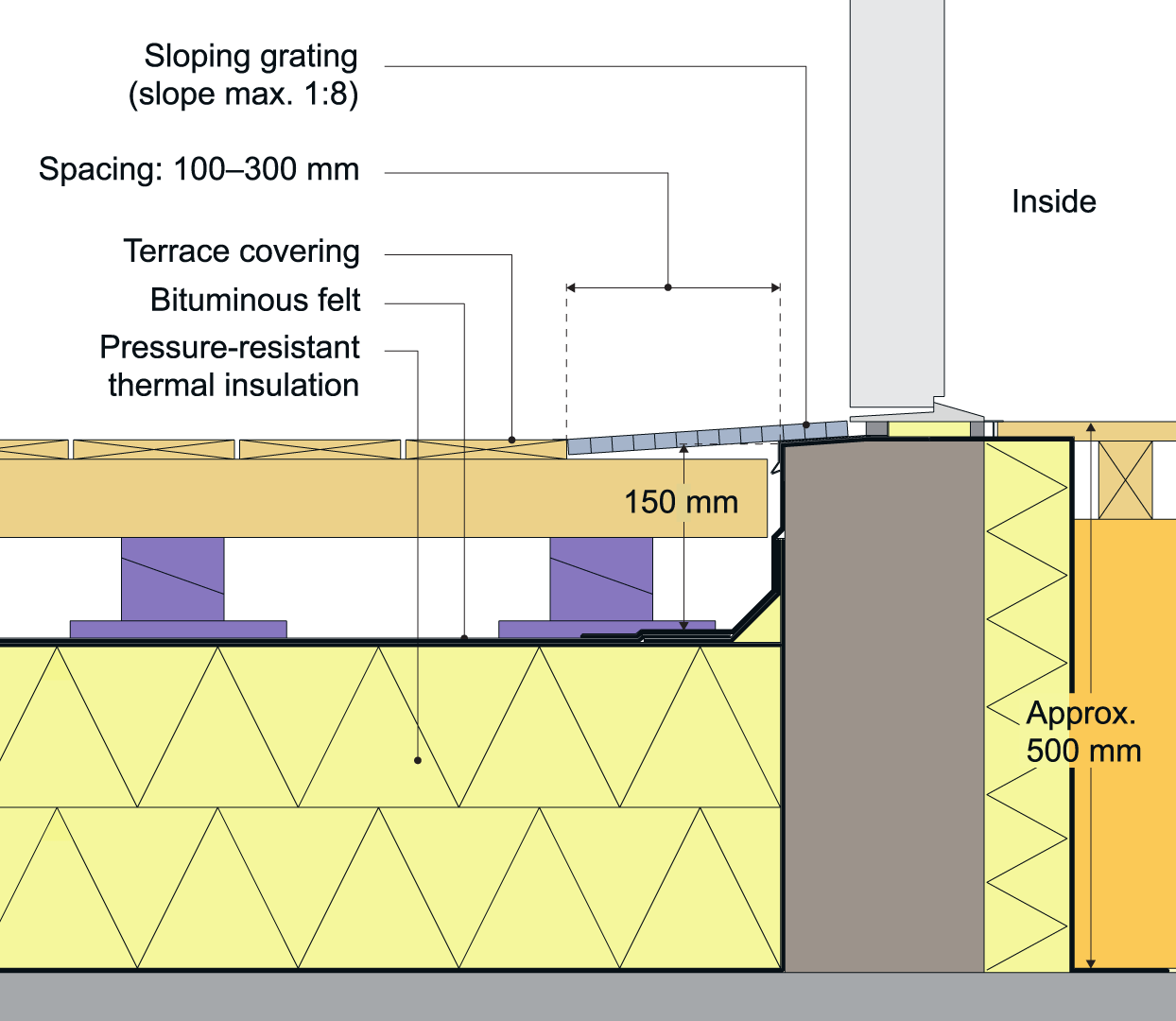

7.3.7 Flashing Roof Terraces

External doors in roof terraces are often required to provide level-free access to the building (BR18, § 51). To achieve the required flashing height of 150 mm at the roof level interface, it is important that the floor assembly inside the building is sufficiently high (a height of 500 mm is often necessary) due to the thick thermal insulation layer in the roof below the roof terrace.

To avoid spray on the facade, a 200-mm-wide grating is normally used along the facade.

If using paving slabs set in sand, the flashing height must be measured from the top of the slabs, which makes it difficult to establish level-free access.

Figure 227. An example of roof terrace flashing for level-free access by an outward-opening door. To achieve the required flashing height of 150 mm, a high floor assembly is needed inside the building (e.g., approx. 500 mm, as shown). The terrace decking in this example is made from wood boards on joists laid on blocking above pressure-resistant thermal insulation with bituminous felt.

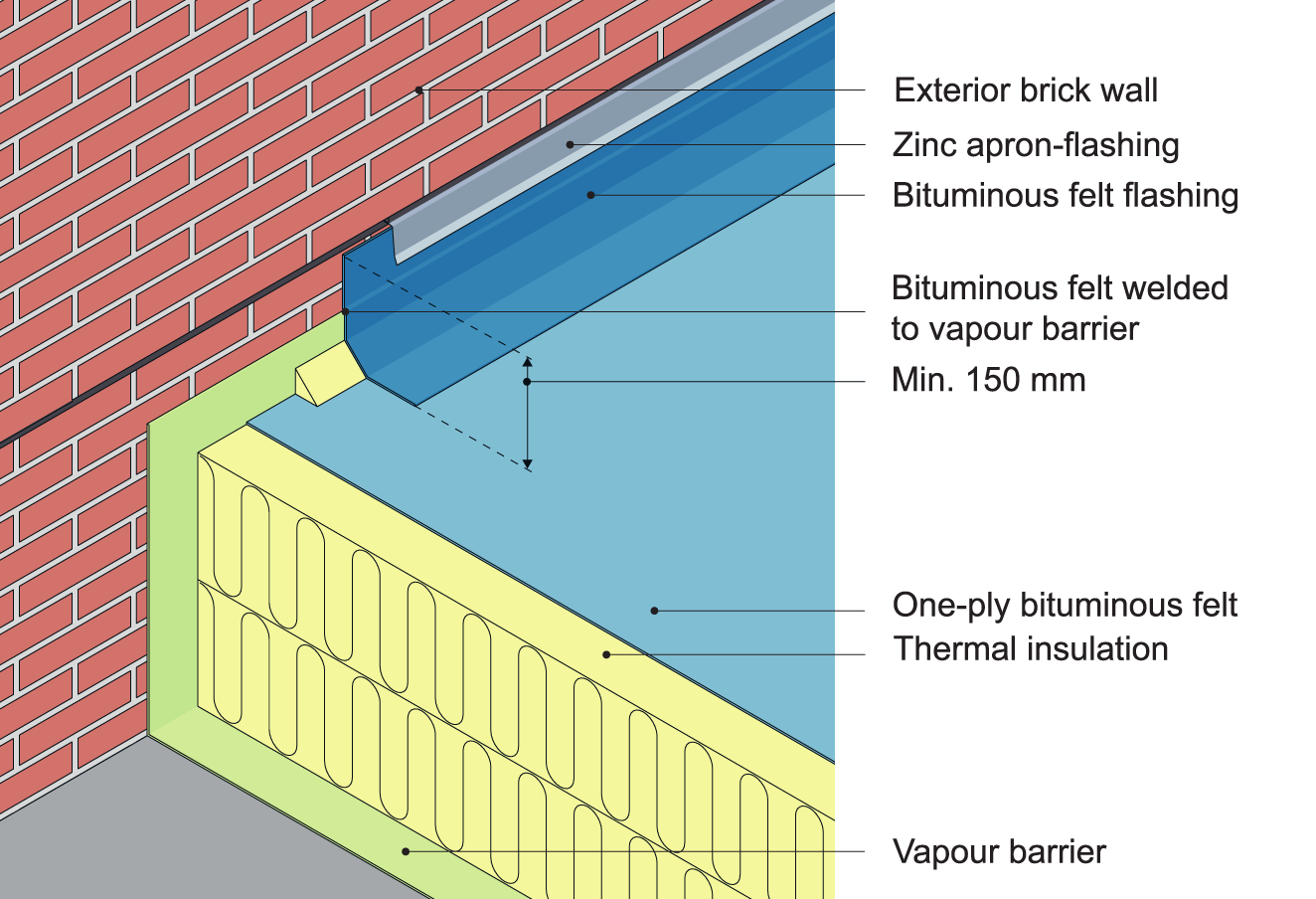

7.3.8 Flashing Facades

Normally, a flashing height of 150 mm is estimated for roofing membrane facade flashing.

Flashing at brick facades must be terminated with counter-flashing and a joint. This should be positioned so that any water from faulty cross joints is discharged to the flashing (see Figure 228).

Smooth concrete wall flashing (and similar assemblies), can be fixed using flashing termination bars or clamping strips (see Figure 229).

General guidelines for roofing membrane flashings to adjoining building parts are outlined in Section 5.7.7, Details – Roofing Membranes.

Special guidelines apply for roofing membrane flashing against adjoining building parts in a green roof (see Section 5.11, Green Roofs).

Figure 228. An example of flashing at the intersection of a brick facade and warm roof with counter-flashing and a sealed joint in one-ply bituminous felt roof covering.

Figure 229. An example of flashing using a flashing termination bar between concrete facade and warm roof with roofing foil covering. The joint between vapour barrier and roofing foil must be tight.

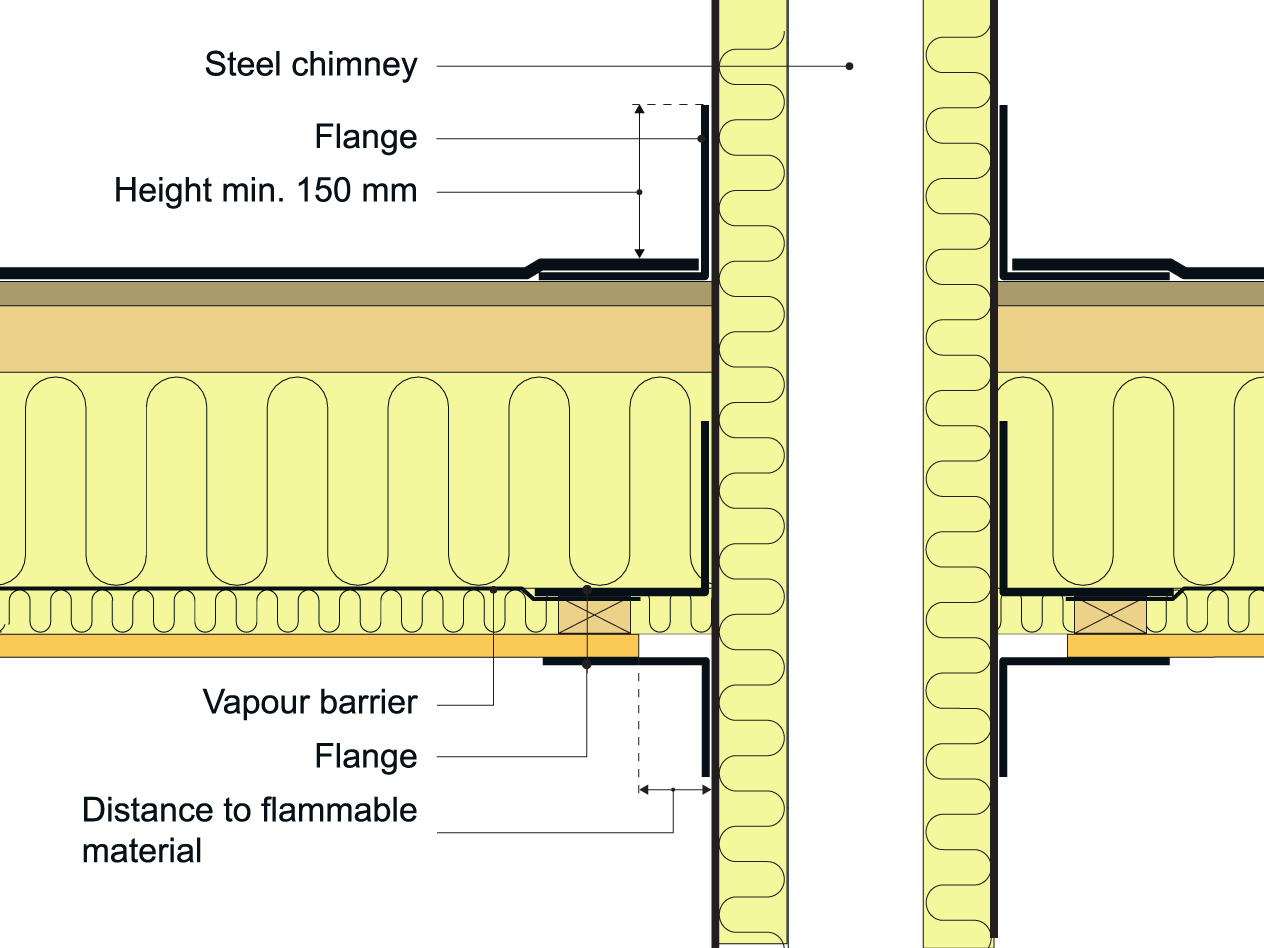

7.3.9 Flashing a Steel Chimney

When flashing a steel chimney, issues of fire safety and moisture must be considered.

CE-labelled steel chimneys provide a min. distance to flammable material. In roof structures, the requirements specifying distance to flammable material apply to both supporting structural parts and the loft. Vapour barriers in roofs are often installed with airtight joints (e.g., using a fire-safe sealing gland) (see Figure 230).

Figure 230. A schematic of a steel chimney penetration in a warm roof. The distance to flammable material is stated in the manufacturer instructions.

7.3.10 Roof Light Flashing

Roof lights must be flashed at the roof-covering and vapour-barrier level.

Issues concerning the installation of roof lights in flat membrane roofs are outlined in Section 6.1, Roof Lights for Flat Roofs.